A kind of catalyst and preparation method thereof, and a kind of method for preparing laurolactam by gas phase rearrangement reaction

A catalyst and fluoride technology, applied in the preparation of lactam, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as equipment corrosion and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

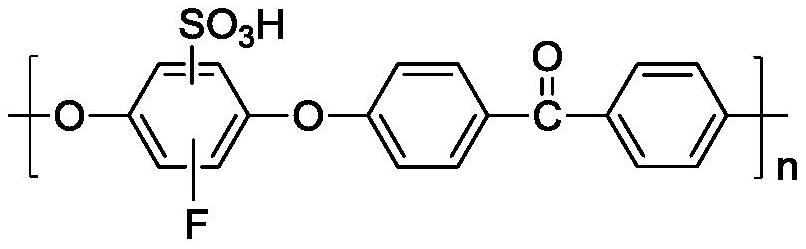

[0047] 1) Rare earth doped fluorine-containing SPEEK / Al 2 O 3 -SiO 2 -ZrO 2 Preparation of composite catalysts

[0048] a) Maintain the system at 0-5°C, dissolve 2g TPAOH in 300g deionized water; at the same time, slowly add 0.042g (tri)scandium nitrate hexahydrate, 0.008g yttrium trichloride, 10g Al(NO) to the deionized aqueous solution of the template agent 3 ) 3 ·9H 2 O, 10g ZrOCl 2 ·8H 2 O, 20g TEOS, feeding time 1h; under stirring condition, slowly add 25% ammonia water dropwise to adjust pH=10, continue stirring for 2h, stop stirring and ageing for 1h; filter under reduced pressure, wash with deionized water to medium The filter cake was dried at 120°C for 28h, then calcined at 500°C for 2h, ground and sieved to obtain rare earth-doped Al 2 O 3 -SiO 2 -ZrO 2 vector.

[0049] b) Take 10 g of rare earth doped Al 2 O 3 -SiO 2 -ZrO 2 The carrier was added to 30 g of a sodium fluoride aqueous solution with a mass fraction of 1%, soaked at 50 °C for 30 min, fil...

Embodiment 2

[0066] 1) Rare earth doped fluorine-containing SPEEK / Al 2 O 3 -SiO 2 -ZrO 2 Preparation of composite catalysts

[0067] a) Maintain the system at 0-5°C, dissolve 3g TPAOH in 300g deionized water; at the same time, slowly add 0.09g (tri)scandium nitrate hexahydrate, 0.01g yttrium trichloride, 12g Al(NO) to the deionized water solution of the template agent 3 ) 3 ·9H 2 O, 10g ZrOCl 2 ·8H 2 O, 25g TEOS, feeding time 1h; under stirring condition, slowly add 25% ammonia solution dropwise to adjust pH=9, continue stirring for 2h, stop stirring and ageing for 1h; filter under reduced pressure, wash with deionized water until Neutral; the filter cake was dried at 120°C for 24h, then calcined at 550°C for 2h, ground and sieved to obtain rare earth-doped Al 2 O 3 -SiO 2 -ZrO 2 vector.

[0068] b) Take 10 g of rare earth doped Al 2 O 3 -SiO 2 -ZrO 2 The carrier was added to 20 g of a sodium fluoride aqueous solution with a mass fraction of 1%, soaked at 50 °C for 30 min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com