Method for manufacturing photoelectric detection unit or focal plane device by using molecular beam epitaxy method

A technology of molecular beam epitaxy and photoelectric detection, which is applied in the direction of electrical components, semiconductor devices, chemical instruments and methods, etc., can solve the problems of complex process, affecting device performance, and difficulty in uniform material diffusion, and achieve high doping efficiency and atomic radius small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

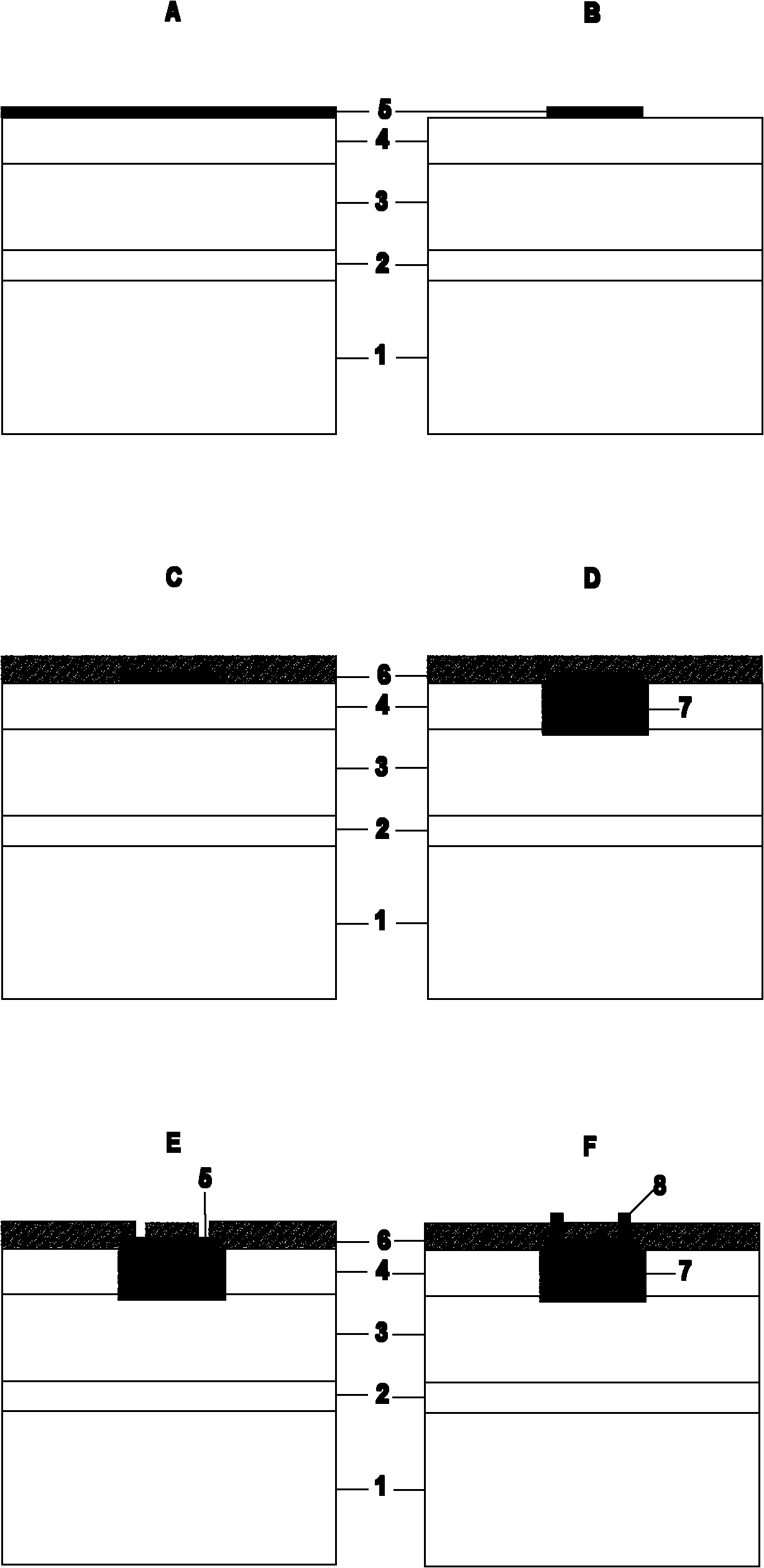

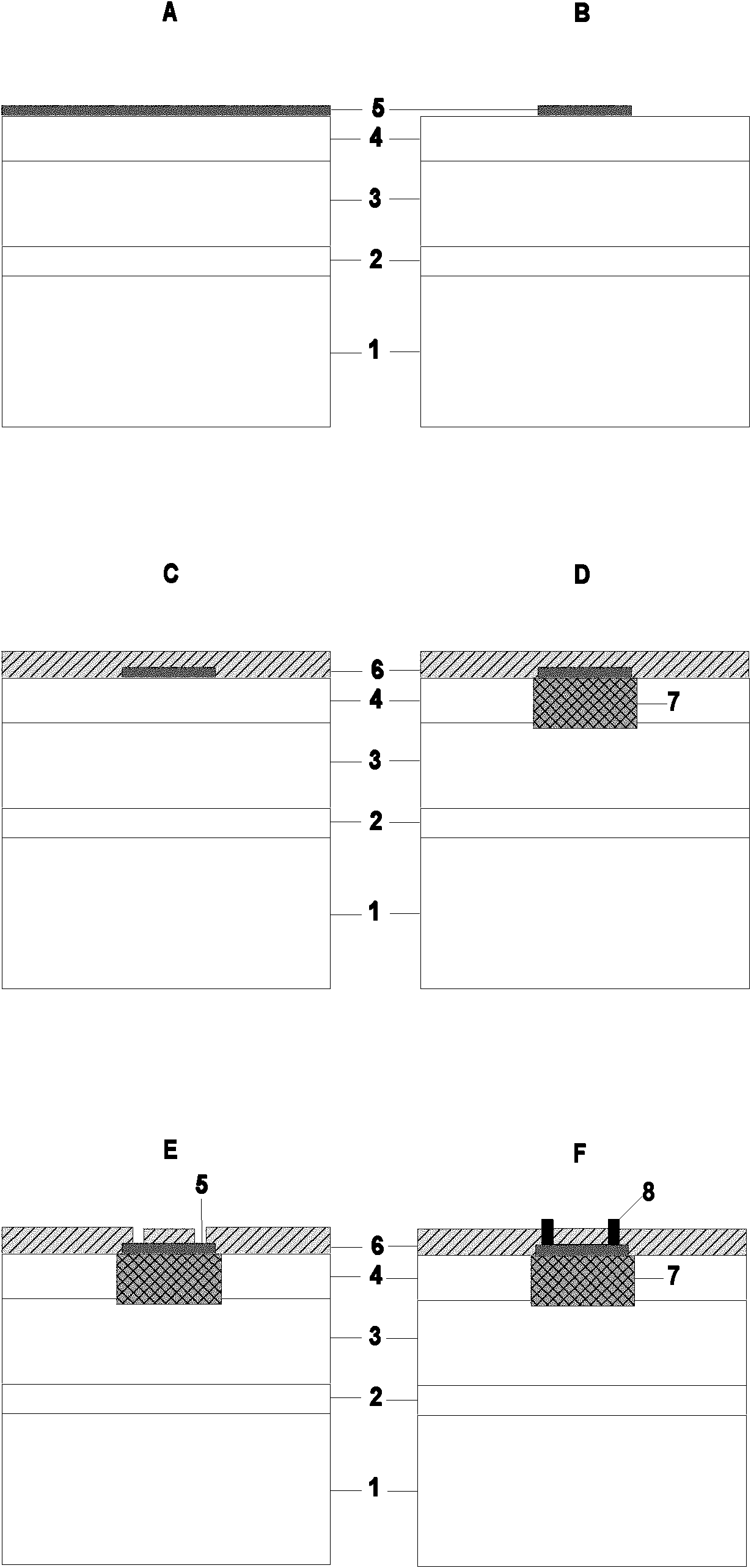

[0023] (1) At first, the molecular beam epitaxy growth technology is used to grow on the InP substrate (1 in the accompanying drawing), including the buffer layer (2 in the accompanying drawing), the InGaAs light absorption layer (3 in the accompanying drawing) and the wide bandgap cap layer (1 in the accompanying drawing). 4) in the figure is suitable for the epitaxial structure of the photodetector device of the planar diffusion process. The InP substrate can be semi-insulating or N-type highly doped conductivity type according to the specific requirements of the device (such as front or back light, packaging and application requirements, etc.); the buffer layer can use wide bandgap such as InP or InAlAs (relative to the absorption layer and The thickness of the material is 500 nanometers, and the doping and its concentration can also be determined according to the final requirements of the device; the InGaAs light absorption layer is unintentionally doped or low-doped n-type...

Embodiment 2

[0031] The embodiment of the present invention is specifically described below by taking the fabrication of a GaAs photodetector device on a GaAs substrate as an example:

[0032] (1) At first, the molecular beam epitaxy growth technique is used to grow on the GaAs substrate (1 in the accompanying drawing), including the buffer layer (2 in the accompanying drawing), the GaAs light absorbing layer (3 in the accompanying drawing) and the wide bandgap AlGaAs cap layer (2 in the accompanying drawing). The epitaxial structure of the photodetection device suitable for planar diffusion process in 4) of the accompanying drawings. The GaAs substrate can use semi-insulating or N-type highly doped conductivity type according to the specific requirements of the device (such as front or back light, packaging and application requirements, etc.); the buffer layer can be GaAs material, the thickness is 500 nanometers, the doping and its concentration It can also be determined according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com