Organic-inorganic composite resistive random access memory and preparation method for same

A resistive memory, inorganic composite technology, applied in static memory, digital memory information, information storage and other directions, can solve the problems of poor device stability, slow switching speed, unfavorable device repeatability and stability, etc. Improve uniformity, uniform and reliable storage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

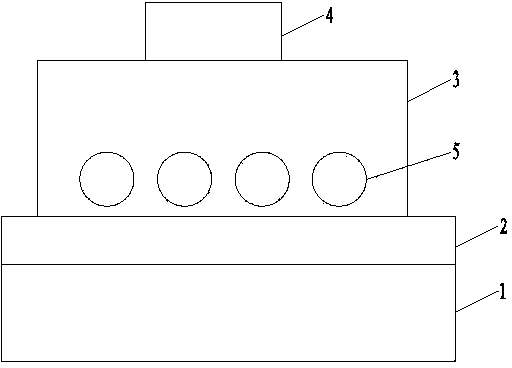

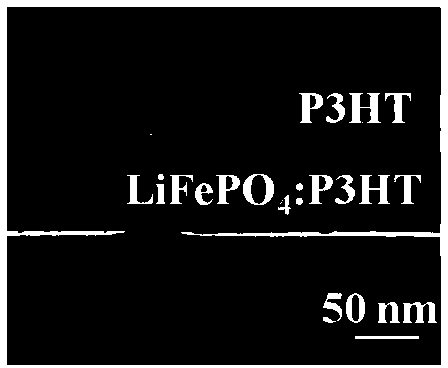

[0024] Such as figure 1 As shown in -4, an organic-inorganic composite resistive variable memory includes a substrate 1, a bottom electrode 2 deposited on the substrate 1 in sequence, an organic-inorganic composite dielectric layer 3 embedded with lithium ion compound particles 5, and a top electrode 4.

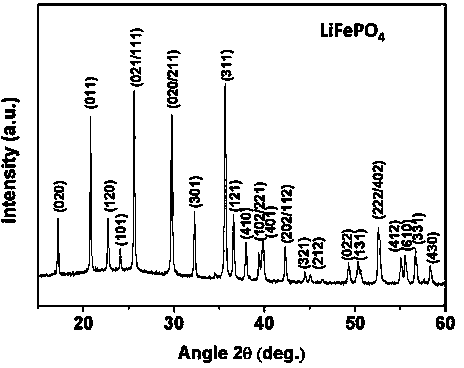

[0025] Mix ferrous iron salt and phosphoric acid solution, pre-calcine at 250-400 °C for 3-15 hours under the protection of inert gas to decompose phosphate and oxalate, and then roast at 450-800 °C for 5-30 hours to obtain Single-phase lithium iron phosphate with an olivine structure is milled at high speed by a nano-grinding machine to particles below 50 nanometers to obtain lithium iron phosphate nanoparticles. figure 2 It is an X-ray diffraction pattern of lithium iron phosphate powder with a particle size of 50nm, and the obtained lithium iron phosphate powder has a pure olivine-type orthorhombic single-phase structure.

[0026] Weigh 1 mg to 1 g of lithium iron phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com