Multifunctional concrete structure steel bar corrosion ratio detector

A concrete structure and steel bar corrosion technology, applied in the field of measuring instruments, can solve the problems of concrete influence, difficult ions, inapplicability of in-service concrete structures, etc., and achieve the effect of improved convenience, easy maintenance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

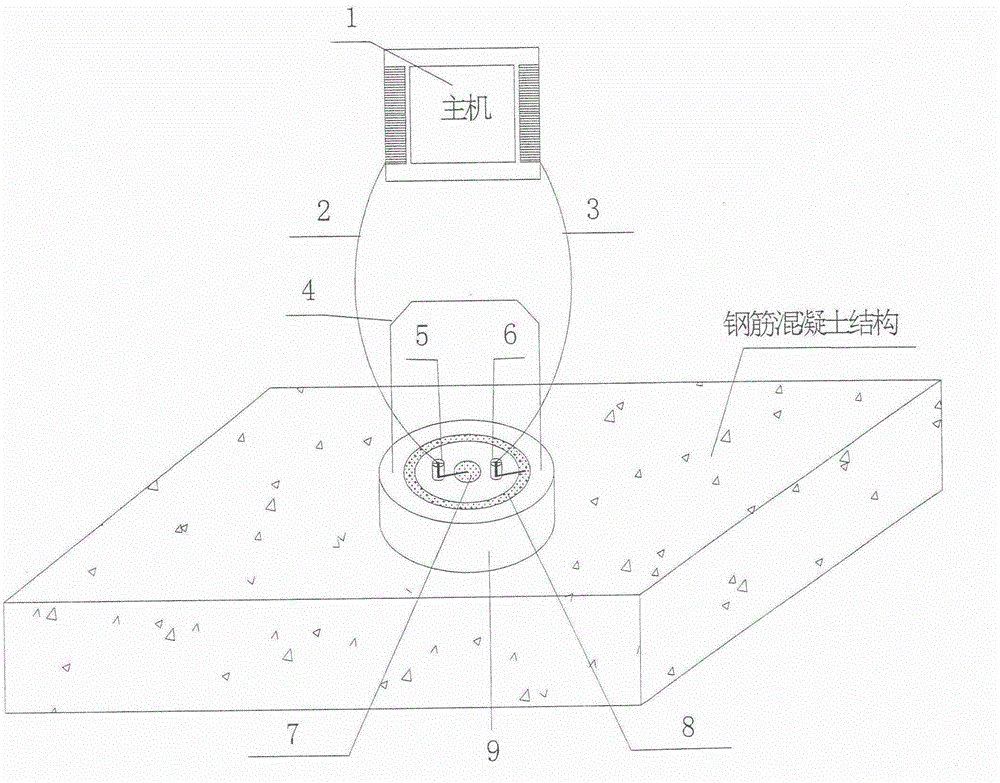

[0025] as attached figure 1 As shown, the multifunctional concrete structure steel bar corrosion rate detector is mainly used to measure the corrosion current density, the average corrosion section loss rate, the carbon dioxide concentration, temperature, and humidity of the environment where the concrete structure is located, and to determine the location, scope, and location of rust pits. degree distribution law. In order to make the instrument more reliable in detecting the corrosion degree of steel bars, the following requirements must be met during actual measurement: the concrete components to be tested must be fully wet, and when the concrete is in a dry state, water should be sprayed on the concrete surface for about 0.5 hours before testing. Control it at 7% to 12%. At this time, the corrosion current density and potential difference are more stable, and the measured corrosion current density, potential difference, and corrosion average section loss rate are more accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com