TiC/316L composite and preparing method thereof

A technology of composite materials and materials, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as poor mechanical properties of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

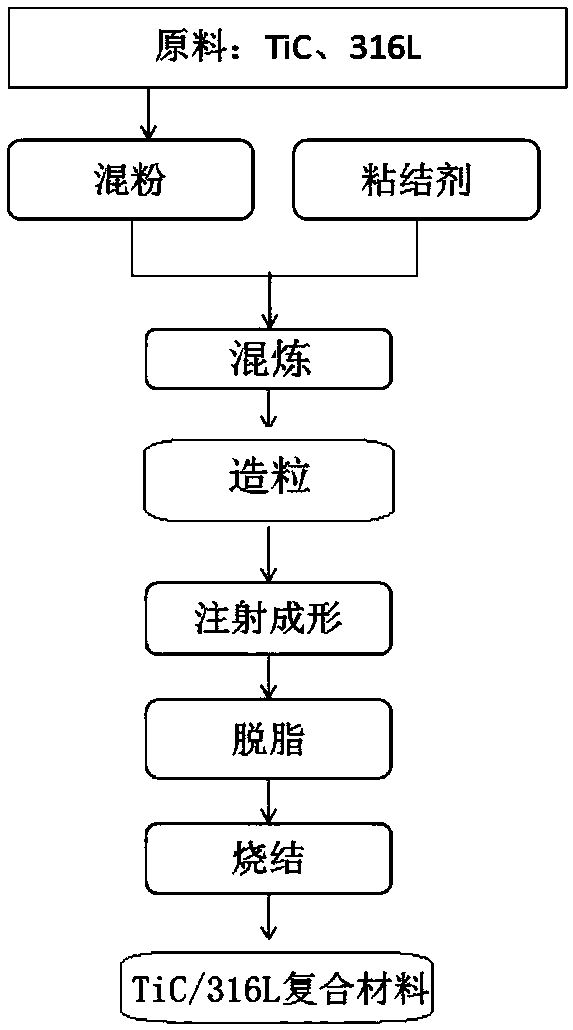

[0029] The invention provides a kind of preparation method of TiC / 316L composite material, comprises the following steps:

[0030] (1) TiC and 316L stainless steel powder are mixed and dried to obtain mixed powder;

[0031] (2) mixing the mixed powder obtained in step (1) with a binder to obtain a mixed material;

[0032] (3) performing granulation and injection molding on the mixed material obtained in step (2) successively to obtain a shaped green body;

[0033] (4) Degreasing and sintering the shaped body obtained in step (3) to obtain a TiC / 316L composite material.

[0034] In the present invention, TiC and 316L stainless steel powder are mixed and dried to obtain mixed powder. In the present invention, the weight percentage of TiC in the mixed powder is preferably 5-8%, more preferably 6-7%; the weight percentage of 316L stainless steel powder in the mixed powder is preferably 92-95%, more preferably 93-94%.

[0035] In the present invention, the 316L stainless steel ...

Embodiment 1

[0063] Mix TiC with a mass percentage of 5% and 316L stainless steel powder with a mass percentage of 95% in a three-dimensional mixing powder machine, the mixing time is 1.5h, and the mixing speed is 20r / min; the TiC / 316L mixture is carried out in a dry box Dry to obtain mixed powder; wherein the drying temperature is 20°C, and the drying time is 1.5h;

[0064] According to the percentage by weight, paraffin wax: high-density polyethylene: stearic acid = 65%: 30%: 5% is formulated as a binder. First, put the binder into the mixing chamber and knead for 10 minutes. One-third of the TiC / 316L mixed powder continued to knead for 15 minutes, when the kneading was uniform, continue to add one-third of the TiC / 316L mixed powder and continued kneading for 15 minutes, and when the kneading was even, continue to add one-third of the TiC / 316L The mixed powder was continuously kneaded for 20 minutes to obtain a kneaded material; wherein, the total time of kneading was 1 h; the kneading t...

Embodiment 2

[0073] Mix TiC with a mass percentage of 5.5% and 316L stainless steel powder with a mass percentage of 94.5% in a three-dimensional mixing powder machine, the mixing time is 2h, and the mixing speed is 21r / min; the TiC / 316L mixture is carried out in a dry box Dry to obtain mixed powder; wherein, the drying temperature is 20°C, and the drying time is 1.2h;

[0074] According to the percentage by weight, it is paraffin wax: high-density polyethylene: stearic acid = 70%: 28%: 2% to prepare a binder, first put the binder into the mixing chamber and knead for 15 minutes, and then add Continue to knead 1 / 3 of the mixed powder for 15 minutes. When the kneading is uniform, continue to add 1 / 3 of the mixed powder and continue kneading for 10 min. Refining material; Wherein, the total time of described mixing is 1h; Described mixing temperature is 145 ℃;

[0075] The mixed material is granulated to obtain granular materials with a particle size of 4mm; the granular materials are injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

| Corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com