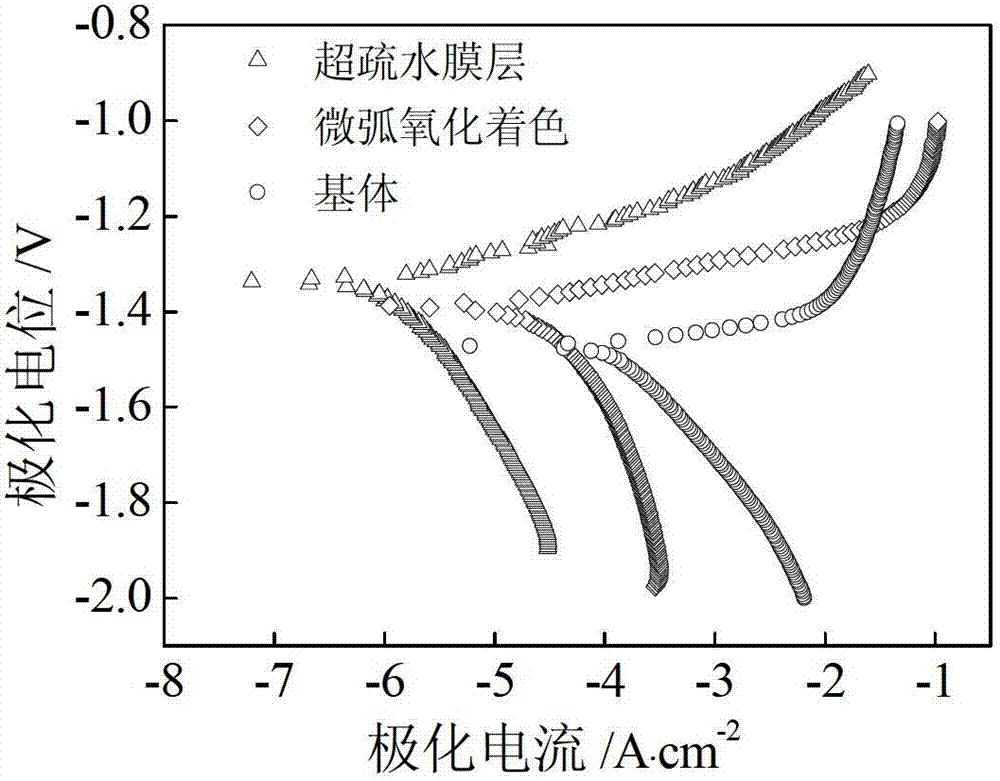

Preparation method for light green superhydrophobic corrosion-resistant film on surface of magnesium-lithium alloy

A magnesium-lithium alloy, light green technology, which is applied in the field of preparation of light green superhydrophobic corrosion-resistant coatings on the surface of magnesium-lithium alloys, can solve the problems of limited corrosion resistance and low corrosion resistance of the coating, and achieve improved corrosion resistance. The effect of corrosion resistance, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the light green superhydrophobic corrosion-resistant film layer on the surface of the magnesium-lithium alloy includes the preparation of the light green ceramic film layer by micro-arc oxidation coloring and the hydrophobic treatment by organic coating. The steps and process conditions are as follows:

[0026] Step 1: Preparation of light green ceramic film layer by micro-arc oxidation coloring

[0027] (1) Pre-treatment of magnesium-lithium alloy:

[0028] Process the magnesium-lithium alloy plate into a thin plate with a size of 50×30×2mm, remove the oxide film after pickling, and then ultrasonically clean it in acetone solution to remove oil and dirt, and dry it with a hair dryer;

[0029] (2) Preparation of micro-arc oxidation colored electrolyte: sodium silicate 20g / L, sodium molybdate 5g / L, sodium hydroxide 10g / L, potassium dichromate 2g / L, polyethylene glycol 2g / L, triethanolamine 5mL / L;

[0030] (3) The micro-arc oxidation coloring t...

Embodiment 2

[0036] Step 1: Preparation of light green ceramic film layer by micro-arc oxidation coloring

[0037] (1) Pre-treatment of magnesium-lithium alloy:

[0038] Process the magnesium-lithium alloy plate into a thin plate with a size of 50×30×2mm, remove the oxide film after pickling, and then ultrasonically clean it in acetone solution to remove oil and dirt, and dry it with a hair dryer;

[0039] (2) Preparation of micro-arc oxidation colored electrolyte: potassium silicate 5g / L, sodium molybdate 10g / L, sodium hydroxide 20g / L, sodium dichromate 4.5g / L, polyethylene glycol 1g / L, three Ethanolamine 10mL / L;

[0040] (3) The micro-arc oxidation coloring treatment is carried out by AC step-increasing and constant-voltage method. The process conditions are: voltage 70-160V, frequency 40Hz, treatment time 30min, and a low-temperature constant temperature bath to control the reaction temperature at 20-40°C.

[0041] Step 2: Hydrophobic treatment of organic coating

[0042] (1) prepare o...

Embodiment 3

[0046] Step 1: Preparation of light green ceramic film layer by micro-arc oxidation coloring

[0047] (1) Pre-treatment of magnesium-lithium alloy:

[0048] Process the magnesium-lithium alloy plate into a thin plate with a size of 50×30×2mm, remove the oxide film after pickling, and then ultrasonically clean it in acetone solution to remove oil and dirt, and dry it with a hair dryer;

[0049] (2) Preparation of micro-arc oxidation colored electrolyte: sodium silicate 40g / L, potassium molybdate 2g / L, sodium hydroxide 5g / L, potassium dichromate 0.5g / L, polyethylene glycol 5g / L, three Ethanolamine 1mL / L;

[0050] (3) The micro-arc oxidation coloring treatment is carried out by AC step-increasing and constant-voltage method. The process conditions are as follows: voltage is 80-160V, frequency is 60Hz, processing time is 10min, and the reaction temperature is controlled by a low-temperature constant temperature bath at 20-40°C.

[0051] Step 2: Hydrophobic treatment of organic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com