Method capable of improving uniformity of porous silicon film physical micro-structure and optical characteristics

A technology of optical properties and porous silicon, which is applied in the directions of microstructure technology, microstructure devices, and manufacturing microstructure devices, etc., can solve the problems of uneven physical microstructure and optical properties of porous silicon films, and achieve the effect of improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment one: the method (1) that can improve the uniformity of the physical microstructure of the porous silicon film, it comprises the following steps:

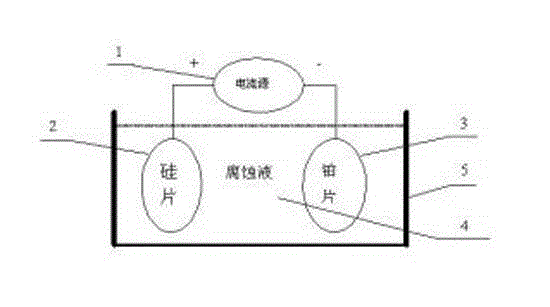

[0019] (1) Connect the circuit as shown in the attached drawing: that is, put the etching solution 4 in the etching tank 5, set the silicon chip 2 at one end of the etching tank, and set the platinum chip 3 at the other end of the etching tank, and the silicon chip 2 and the platinum sheet 3 are immersed in the etching solution 4, and a current source 1 is provided outside the etching tank, the positive pole of the current source is connected to the silicon wafer 2 through a wire, and the negative electrode of the current source is connected to the platinum sheet 3 through a wire;

[0020] (2) The type of silicon chip is P100, the resistivity is 0.01Ω.cm, the silicon chip is used as the anode of electrochemical corrosion, and the thin platinum sheet is used as the cathode of electrochemical corrosion; the silicon c...

Embodiment 2

[0027] Embodiment two: the method (two) that can improve the uniformity of the physical microstructure of the porous silicon film, it comprises the following steps:

[0028] (1) Connect the circuit as shown in the attached figure, that is, put the etching solution 4 in the etching tank 5, set the silicon wafer 2 at one end of the etching tank, and set the platinum wafer 3 at the other end of the etching tank, and the silicon wafer 2 and the platinum sheet 3 are immersed in the etching solution 4, and a current source 1 is provided outside the etching tank, the positive pole of the current source is connected to the silicon wafer 2 through a wire, and the negative electrode of the current source is connected to the platinum sheet 3 through a wire; wherein the current The decreasing corrosion current of the source is completed under computer control;

[0029] (2) The silicon wafer is selected as a P-type silicon wafer, and the resistivity is 0.007~0.01Ω.cm. The corrosion solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com