Magnesium alloy surface hydrophobization compound processing method

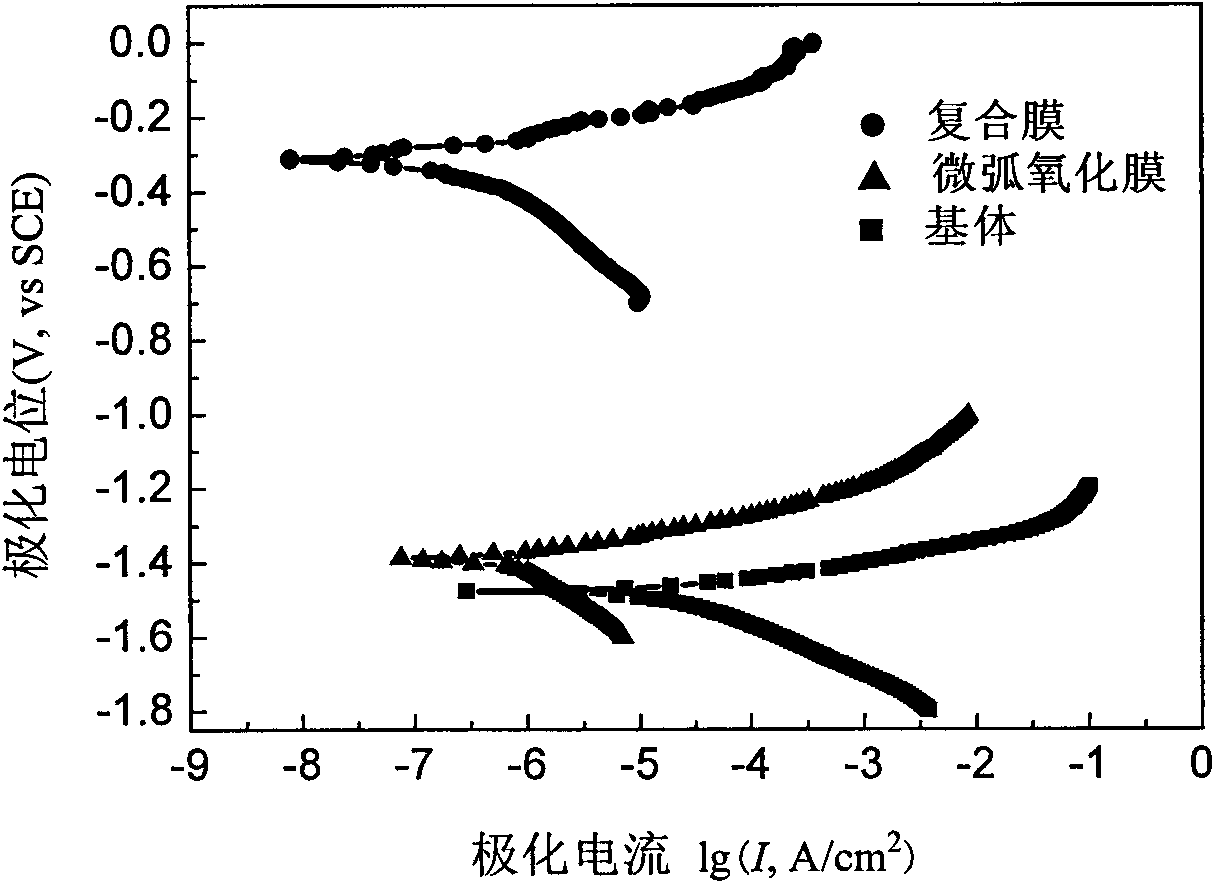

A composite treatment, magnesium alloy technology, applied in the direction of anodic oxidation, etc., can solve the problems of super-hydrophobic surface service life limit, complex process, not ideal, etc., to achieve the effect of smooth and delicate hand feeling, high processing efficiency, dense and orderly growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The implementation workpiece is Mg-Al-Zn series AZ31 magnesium alloy plate, the size is 50×30×1.5 (mm), and the magnesium alloy surface hydrophobization composite treatment method using the combination of micro-arc oxidation and organic coating technology specifically includes the following steps and processes condition:

[0037] Step 1: Micro-nanoporous superhydrophilic surface prepared by micro-arc oxidation

[0038] (1) Pretreatment of magnesium alloy workpieces

[0039]Grind the AZ31 magnesium alloy workpiece with 120#, 360#, 800# sandpaper, put it in acetone solution and ultrasonically clean it for 10 minutes to remove oil stains, take it out and dry it with cold air for later use;

[0040] (2) Micro-arc oxidation treatment

[0041] The pre-treated magnesium alloy workpiece is used as the working electrode. Both electrodes are working electrodes and film is formed at the same time. The micro-arc oxidation treatment is carried out in the form of AC constant voltag...

Embodiment 2

[0051] The implementation workpiece is Mg-Al-Zn series AZ31 magnesium alloy plate, the size is 50×30×1.5 (mm), and the magnesium alloy surface hydrophobization composite treatment method using the combination of micro-arc oxidation and organic coating technology specifically includes the following steps and processes condition:

[0052] Step 1: Micro-nanoporous superhydrophilic surface prepared by micro-arc oxidation

[0053] (1) Pretreatment of magnesium alloy workpieces

[0054] Grind the AZ31 magnesium alloy workpiece with 120#, 360#, 800# sandpaper, put it in acetone solution and ultrasonically clean it for 10 minutes to remove oil stains, take it out and dry it with cold air for later use;

[0055] (2) Micro-arc oxidation treatment

[0056] The pre-treated magnesium alloy workpiece is used as the working electrode. Both electrodes are working electrodes and film is formed at the same time. The micro-arc oxidation treatment is carried out in the way of alternating curren...

Embodiment 3

[0064] The implementation workpiece is Mg-Al-Zn series AZ31 magnesium alloy plate, the size is 50×30×1.5 (mm), and the magnesium alloy surface hydrophobization composite treatment method using the combination of micro-arc oxidation and organic coating technology specifically includes the following steps and processes condition:

[0065] Step 1: Micro-nanoporous superhydrophilic surface prepared by micro-arc oxidation

[0066] (1) Pretreatment of magnesium alloy workpieces

[0067] Grind the AZ31 magnesium alloy workpiece with 120#, 360#, 800# sandpaper, put it in acetone solution and ultrasonically clean it for 10 minutes to remove oil stains, take it out and dry it with cold air for later use;

[0068] (2) Micro-arc oxidation treatment

[0069] The pre-treated magnesium alloy workpiece is used as the working electrode. Both electrodes are working electrodes and film is formed at the same time. The micro-arc oxidation treatment is carried out in the form of AC constant volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com