System and method for testing local corrosion of multi-electrode coupled inhomogeneous structure

A test system and local corrosion technology, applied in the field of electrochemistry, can solve the problem of inability to localize measurement or scan the electrochemical characteristics of different positions on the surface of the electrode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: Carry out partial electrochemical test to microelectrode array by microelectrode array test system, its specific steps are as follows:

[0066] After all the array electrodes are coupled by the high-speed matrix switch of the microelectrode array test system, the galvanic potential and galvanic current of the array electrodes are scanned one by one through the high-speed matrix switch to obtain the galvanic corrosion state and localized corrosion of the microelectrode array current density.

[0067] The test process is: open the microelectrode array test system software, use the high-speed matrix switch to couple all the array electrodes, and then regularly scan the galvanic couple potential and galvanic current of the array electrodes one by one, generally every 2 hours, or 1 Scan every day, or every 5 days.

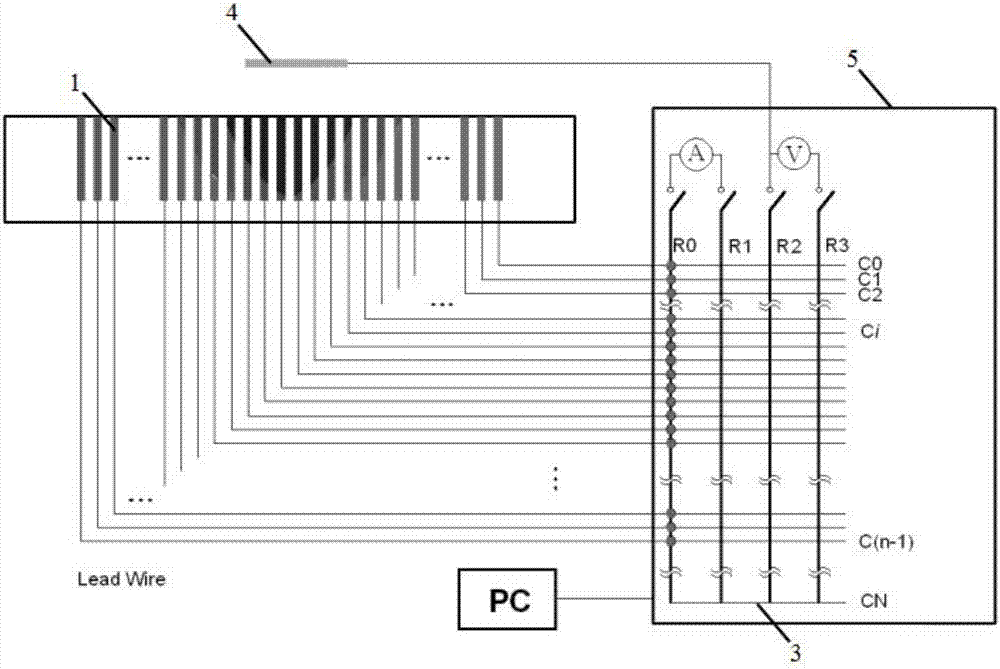

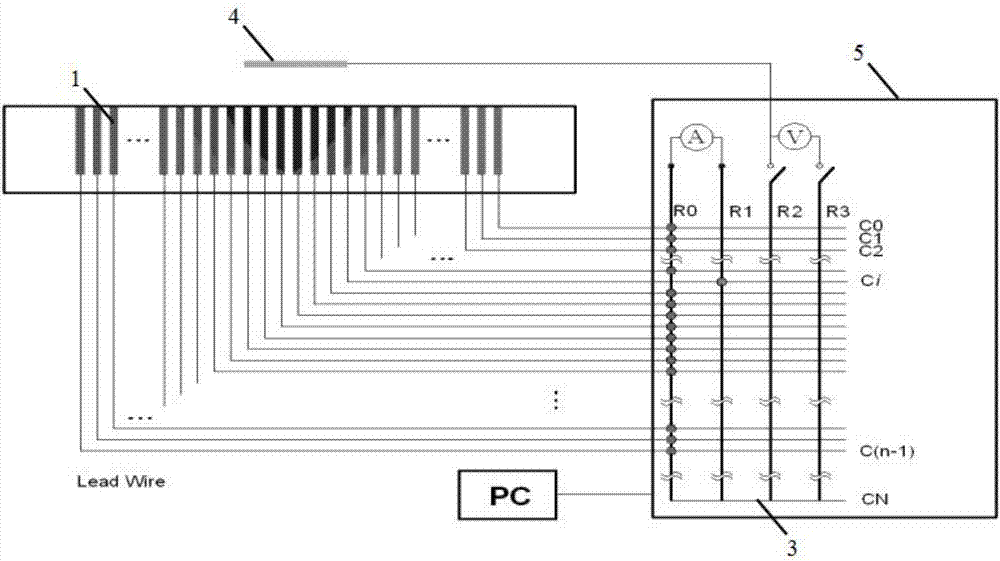

[0068] Take the scanning test of the i-th array electrode as an example to illustrate the above scanning process, see Figure 1a-Figure 1d , Fi...

Embodiment 2

[0069] Embodiment 2: Carry out classical electrochemical test to microelectrode array by microelectrode array test system and classic electrochemical comprehensive test system, its specific steps are as follows:

[0070] see Figure 2a , use the high-speed matrix switch of the microelectrode array test system to couple a certain part of the microelectrode array together as the working electrode, and connect it to the working electrode terminal of the classic electrochemical comprehensive test system. The parameters of the classic electrochemical comprehensive test system The terminal of the specific electrode is connected to the reference electrode, the terminal of the auxiliary electrode of the classic electrochemical comprehensive test system is connected to the auxiliary electrode, the working electrode, reference electrode and auxiliary electrode are placed in the electrolyte solution of the electrolytic cell, and the open circuit potential, Linear polarization resistance,...

Embodiment 3

[0077] Embodiment 3: Carry out classic electrochemical test to microelectrode array by microelectrode array test system and classic electrochemical comprehensive test system, its specific steps are as follows:

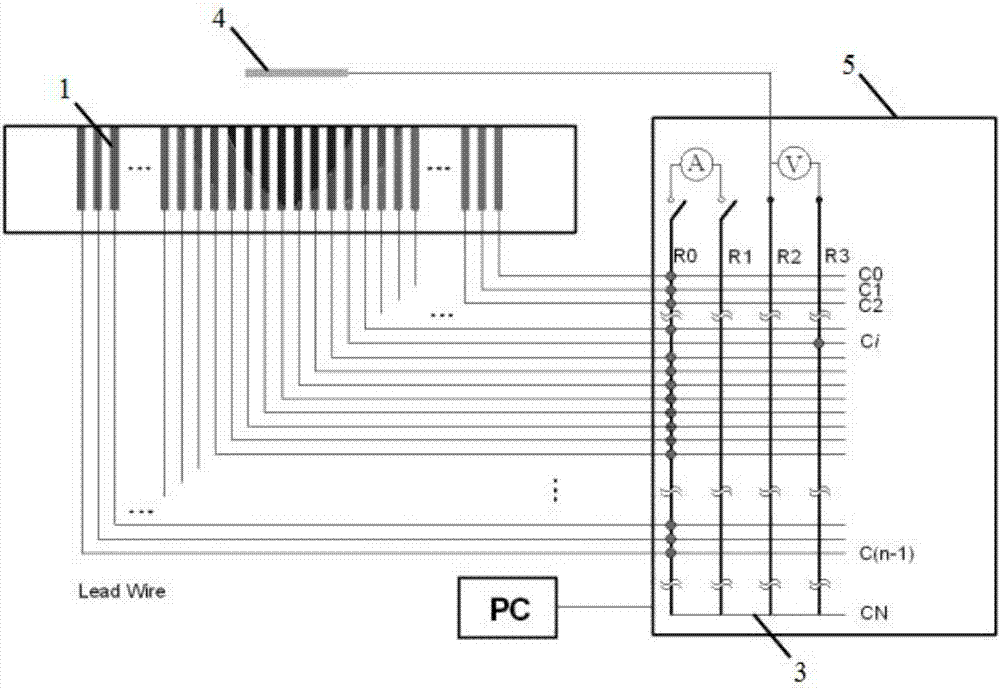

[0078] see Figure 3a , the microelectrode in the local area of interest is switched by the high-speed matrix switch of the microelectrode array test system, and the output end of the high-speed matrix switch is connected to the working electrode terminal of the classic electrochemical comprehensive test system, the classic electrochemical comprehensive test system The reference electrode terminal of the test system is connected to the reference electrode, the auxiliary electrode terminal of the classic electrochemical comprehensive test system is connected to the auxiliary electrode, and the working electrode, reference electrode and auxiliary electrode are placed in the electrolyte solution of the electrolytic cell to perform array electrode The electrochemical imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com