Local electrochemical information testing system and method for three-electrode array

A testing method and information testing technology, applied in the field of electrochemical testing, can solve the problems of inability to obtain local current, impedance and other data, inability to use micro-area electrochemical technology, and insufficient testing information to achieve the accuracy of potential testing. High, not easy to break, the effect of uniform distribution of power lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

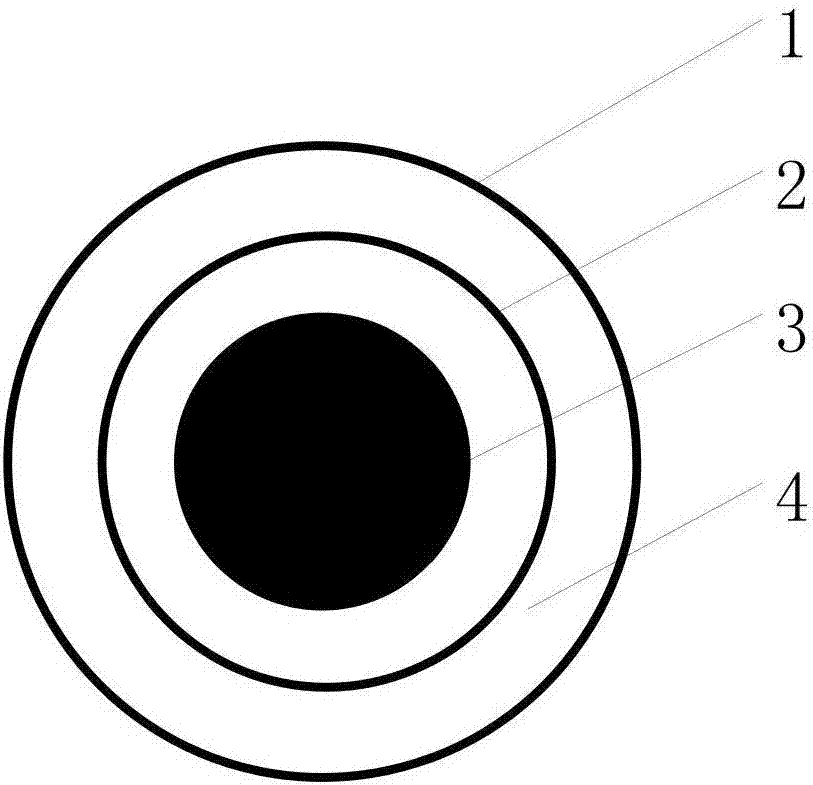

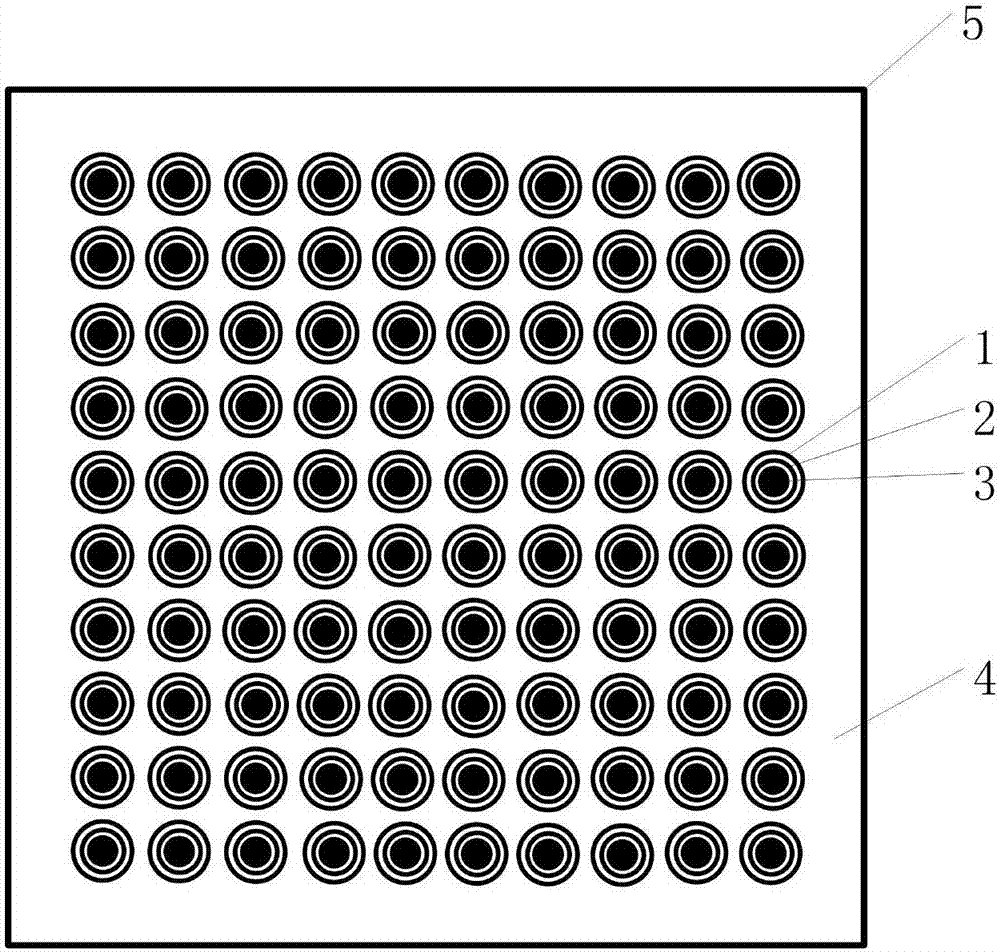

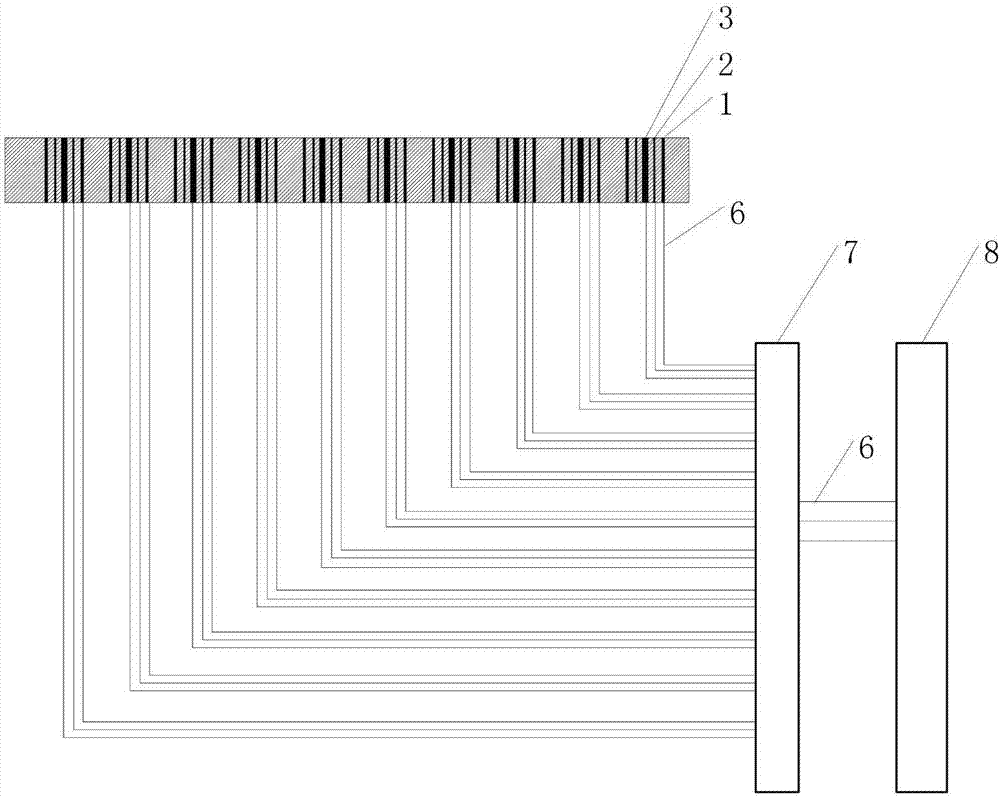

[0040] Embodiment 1 of the present invention: as figure 1 , figure 2 and image 3 As shown, a three-electrode array local electrochemical information testing system includes a concentric three-electrode array 5, a high-speed switch 7, and an electrochemical workstation 8 that are electrically connected by wires 6 in turn. The concentric three-electrode array 5 includes several Concentric three-electrode units, adjacent concentric three-electrode units are separated by insulating material 4; the concentric three-electrode units include annular auxiliary electrodes 1, solid reference electrodes 2 and filamentary working electrodes 3, the The ring-shaped auxiliary electrode 1 and the solid-state reference electrode 2 are both ring-shaped, the wire-shaped working electrode 3 is located in the solid-state reference electrode 2, and the wire-shaped working electrode 3 and the solid-state reference electrode 2 are separated by an insulating material 4; the solid-state reference elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com