High-strength bolt delayed fracture test method and apparatus thereof

A technology for high-strength bolts and delayed fracture, which is applied to measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as cumbersome methods and inconvenient mass evaluation tests

Inactive Publication Date: 2014-12-31

BAOSHAN IRON & STEEL CO LTD

View PDF11 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method is scientific to evaluate the performance of bolts from the perspective of fracture toughness, but this method is cumbersome and inconvenient for large-scale evaluation tests

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

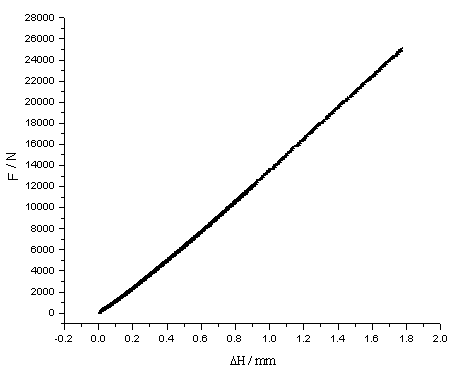

[0022] The implementation cases of the above equipment can be shown in the following table:

[0023]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

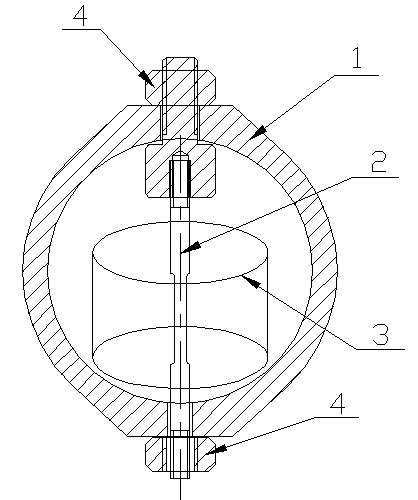

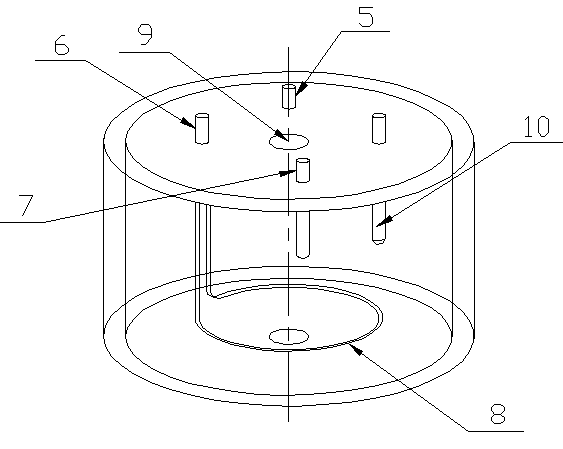

The invention relates to the field of bolt quality control, and especially relates to a method for examining a bolt under simulated actual use conditions, and an apparatus thereof. A high-strength bolt delayed fracture test method comprises the following steps: applying a constant tensile force F to a tested bolt according to the service environment of the tested bolt, simulating the service environment of the tested bolt, and determining the corrosion current density iS under the service environment; and changing the medium solution, the atmosphere and the temperature in an environment container, carrying out acceleration test, determining the corrosion current density iA, calculating to obtain a speed-up ratio, and carrying out acceleration test by using changed parameters to obtain the delay fracture resistance. A high-strength bolt delayed fracture test apparatus comprises a pressure ring and the environment container, the tested bolt is arranged in the environment container, and two ends of the tested bolt are fixedly connected with the pressure ring. The high-strength method and the apparatus thereof can be used for evaluating the delayed fracture resistance of the bolt under the stimulated actual service conditions of the bolt, and predicting the actual service life of the bolt in an acceleration test medium.

Description

technical field [0001] The invention relates to the field of bolt quality control, in particular to a bolt inspection method and device under simulated actual working conditions. Background technique [0002] High-strength bolts used in industrial atmosphere, marine atmosphere and marine environment often face the problem of delayed fracture. Delayed fracture refers to the phenomenon of brittle fracture suddenly occurring after the bolt has been in service for a period of time under stress. Relevant studies have shown that delayed fracture is caused by bolts. The corrosion electrochemical reaction that occurs during service leads to internal hydrogen permeation. In addition, the alternating load and material creep of bolts during service are also important factors that promote delayed fracture. In order to evaluate high-strength bolts, especially high-strength bolts above grade 12.9, research institutions at home and abroad have developed a series of evaluation methods. [...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08G01N17/02

Inventor 杨建强张弛蔡海燕赵社平

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com