Enamel coating electrode as well as preparation method and corrosion resistance test method

A technology of coated electrodes and testing methods, applied in the field of electrochemical materials, to achieve the effects of short time consumption, flat sides, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

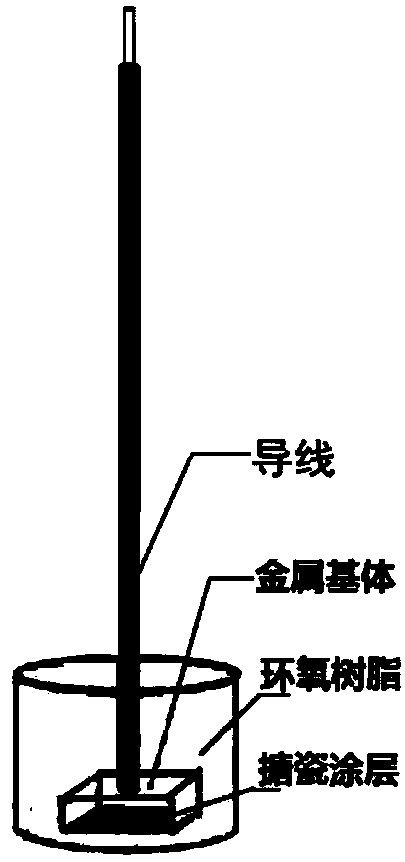

[0046] In the present invention, any enamel coating can be used as a sample to be tested, and the method of the present invention is used to prepare an enamel coating electrode, so as to measure the corrosion resistance of the enamel coating. Further, the metal substrate of the enamel coating is any one of low carbon steel, enamel steel or copper and copper alloy steel. Furthermore, the copper alloy steel is any one of Cu-5Zn, Cu-5Sn or Cu-5Sn-5Zn. Specifically, the present invention firstly provides a method for preparing an enamel-coated electrode, comprising the following steps:

[0047] (1) Carry out cutting, grinding, grinding, water washing, absolute ethanol washing or acetone washing to the enamel coating to remove water, dry for later use;

[0048] (2) wire is welded on the surface of the metal substrate of the enamel coating after the pretreatment in step (1), and the whole body will be put into the PVC container after welding;

[0049] (3) Remove bubbles after mixi...

Embodiment 1

[0075] Preparation of enamel-coated electrode: Prepare a 12mm×12mm sample with the enamel coating on the copper substrate, and grind the edges around to make the side of the enamel coating smooth, free from devitrification and cracking. The back of the enamel coating is ground, polished, cleaned, copper core wire welded, and then put into PVC pipes. Epoxy resin and curing agent ethylenediamine are mixed at a mass ratio of 3.5:1, placed at 50°C for 10 minutes to remove air bubbles, and the mass ratio of epoxy resin to plasticizer dibutyl phthalate is 8:1. Dibutyl phthalate is added to the constant temperature mixture of epoxy resin and ethylenediamine, mixed evenly, and then poured into the PVC model, and the small bubbles around the coating are lightly picked up and removed by floating. The electrode was taken out after curing for 24 hours, polished, eluted with absolute ethanol, and dried to prepare an enamel-coated electrode.

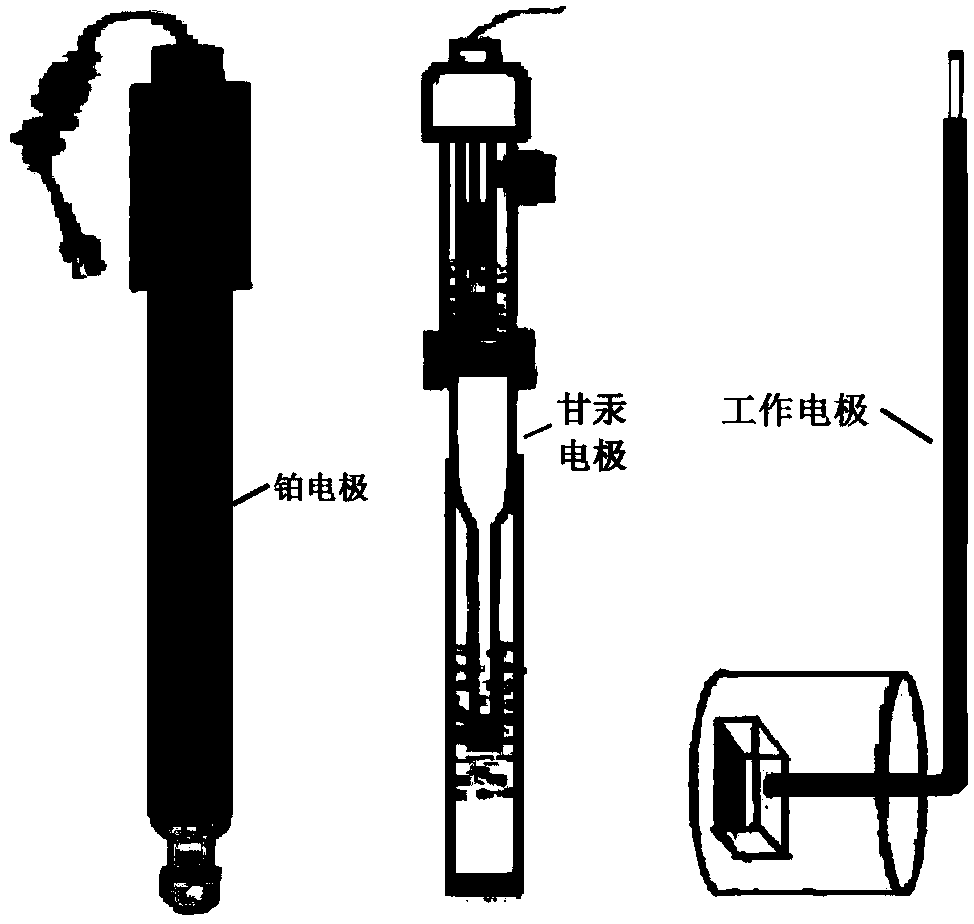

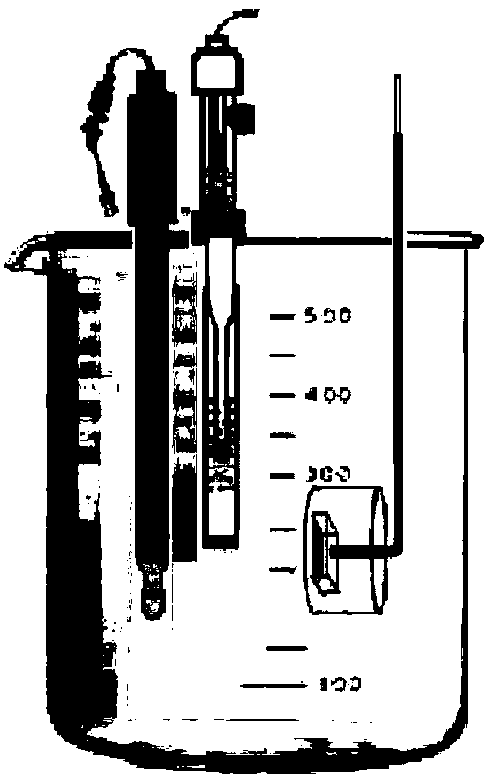

[0076] Acid corrosion test: according to Fig...

Embodiment 2

[0078] Preparation of enamel-coated electrode: The enamel coating of carbon steel Q235 substrate is used to prepare a 12mm×12mm sample, and the edges around it are ground to make the side of the enamel coating smooth, without devitrification and cracking. The back of the enamel coating is ground, polished, cleaned, copper core wire welded, and then put into PVC pipes. Epoxy resin and curing agent ethylenediamine are mixed at a mass ratio of 4:1, placed at 50°C for 10 minutes to remove air bubbles, and the mass ratio of epoxy resin to plasticizer dibutyl phthalate is 7.8:1. Dibutyl phthalate is added to the constant temperature mixture of epoxy resin and ethylenediamine, mixed evenly, and then poured into PVC pipes, and the small bubbles around the coating are lightly picked up and removed by floating. The electrode was taken out after curing for 24 hours, polished, eluted with absolute ethanol, and dried to prepare an enamel-coated electrode.

[0079] Acid corrosion test: acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com