Method for preparing corrosion protection abrasion resistant ceramic coating with alloy surface differential arc oxidization

A technology of micro-arc oxidation and ceramic coating, applied in anodizing and other directions, can solve the problems of uncovered coating, production capacity limitation, superposition, etc., and achieve the effect of fast film forming speed and low unit power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

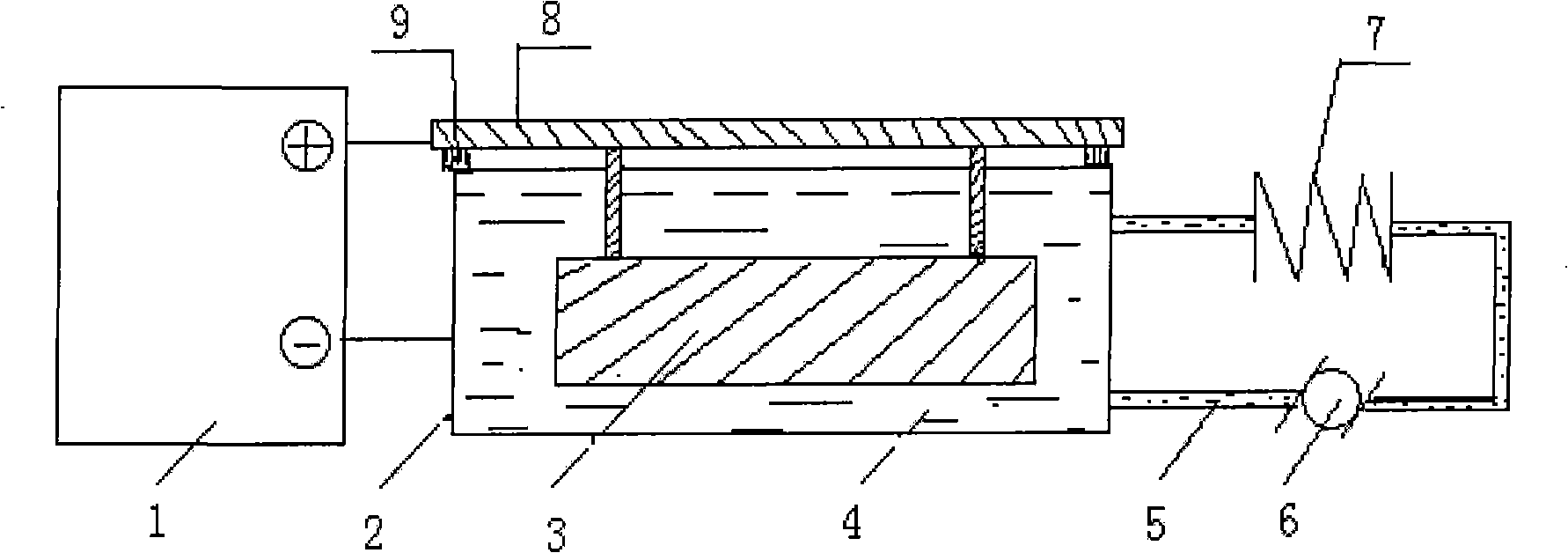

Image

Examples

Embodiment 1

[0021] Example 1: Treat a batch of LY12 aluminum alloy components with a total internal and external surface area of 0.3 square meters

[0022] A method for preparing an anti-corrosion and anti-wear ceramic coating by micro-arc oxidation on the surface of an aluminum alloy, comprising the following steps and process conditions:

[0023] (1) Prepare electrolyte: prepare 100L electrolyte solution, electrolyte composition: sodium silicate 50g / L, sodium hydroxide 5g / L, organic amine 5ml / L (among which ethylenediamine accounts for 50%, triethanolamine accounts for 50%) And other auxiliary additives 11g / L (among them, ethylenediaminetetraacetic acid disodium salt 2g / l, borax 5g / l, sodium tungstate 3g / l and sodium tripolyphosphate 1g / l).

[0024] (2) Set the electrical parameters of the power supply: the output of the power supply is an asymmetrical AC pulse, the minimum voltage is set to -500V, and the pulse height is controlled by the current size: the maximum current is set to 3...

Embodiment 2

[0027] Example 2: processing a batch of LY12 aluminum alloy components with a total internal and external surface area of 0.3 square meters

[0028]A method for preparing an anti-corrosion and anti-wear ceramic coating by micro-arc oxidation on the surface of an aluminum alloy, comprising the following steps and process conditions:

[0029] (1) Prepare electrolyte: prepare 100L electrolyte solution, electrolyte composition: sodium silicate 50g / L, sodium hydroxide 5g / L, organic amine 5ml / L (among which ethylenediamine accounts for 50%, triethanolamine accounts for 50%) And other auxiliary additives 11g / L (among them, ethylenediaminetetraacetic acid disodium salt 2g / l; borax 5g / l; sodium tungstate 3g / l; sodium tripolyphosphate 1g / l).

[0030] (2) Set the electrical parameters of the power supply: the output of the power supply is an asymmetrical AC pulse, the minimum voltage is set to -500V, and the pulse height is controlled by the current size: the maximum current is set to ...

Embodiment 3

[0034] Embodiment 3: processing a batch of LY12 aluminum alloy components, the total internal and external surface area is 0.3 square meters

[0035] A method for preparing an anti-corrosion and anti-wear ceramic coating by micro-arc oxidation on the surface of an aluminum alloy, comprising the following steps and process conditions:

[0036] (1) Configure electrolyte: configure 100L of electrolyte solution, and the electrolyte components are: sodium silicate 50g / L; sodium hydroxide 5g / L; organic amine 5ml / L, wherein ethylenediamine accounts for 50%, and triethanolamine accounts for 50%; Other auxiliary additives 11g / L (among them, disodium ethylenediaminetetraacetic acid 2g / l; borax 5g / l; sodium tungstate 3g / l; sodium tripolyphosphate 1g / l).

[0037] (2) Set the electrical parameters of the power supply: the output of the power supply is an asymmetrical AC pulse, the minimum voltage is set to -500V, and the pulse height is controlled by the current size: the maximum current s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com