Method for preparing biomedical titanium and titanium alloy surface antibacterial coatings

A surface antibacterial, titanium alloy technology, applied in the direction of surface reaction electrolytic coating, metal material coating process, coating, etc., can solve the problems of silver content reduction, difficult antibacterial effect, etc., achieve high production efficiency, avoid bacterial infection, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

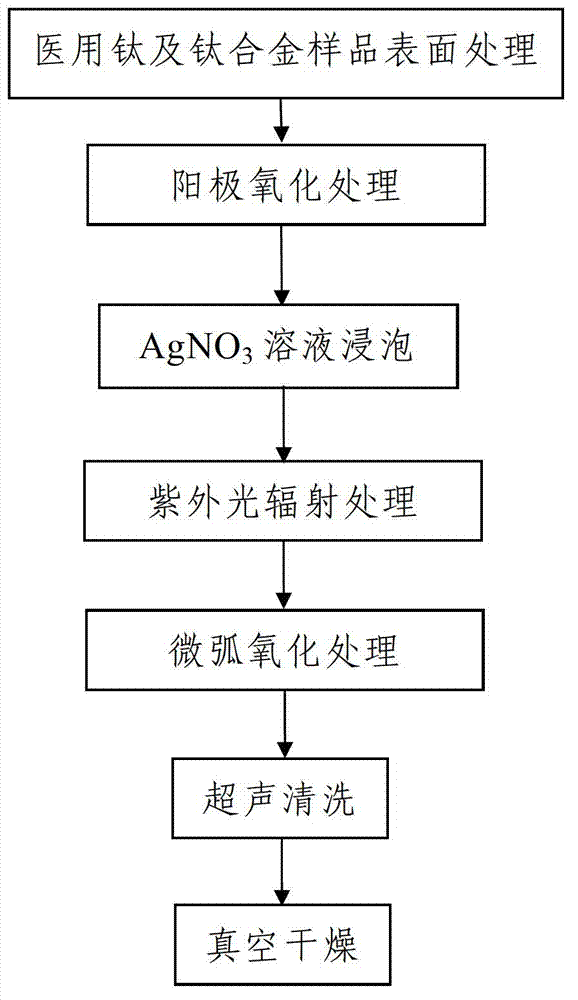

Method used

Image

Examples

Embodiment 1

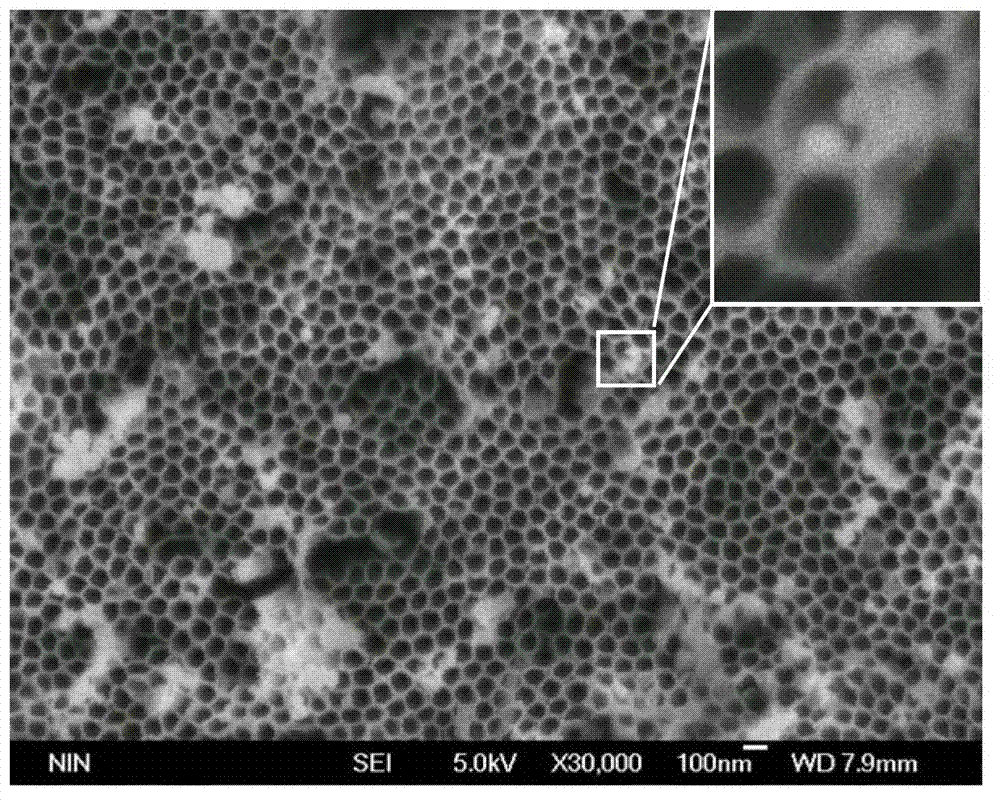

[0029] Step 1. Preparation of TiO on the surface of the medical pure titanium sample to be treated 2 Nanotube Precoat:

[0030] 101. Polish the medical pure titanium sample to be treated to the mirror surface, then ultrasonically clean the polished medical pure titanium sample with distilled water, acetone and absolute ethanol in sequence, and then vacuum dry the medical pure titanium sample after ultrasonic cleaning with absolute ethanol ;

[0031] 102. Completely immerse the medical pure titanium sample after vacuum drying in 101 in the 4 In the ethylene glycol aqueous solution of F, the anodic oxidation treatment was carried out under the condition of 50V constant potential for 1h; the said containing NH 4 The mass concentration of ethylene glycol in the ethylene glycol aqueous solution of F is 95%, and the NH 4 The mass concentration of F is 2%, and the balance is water;

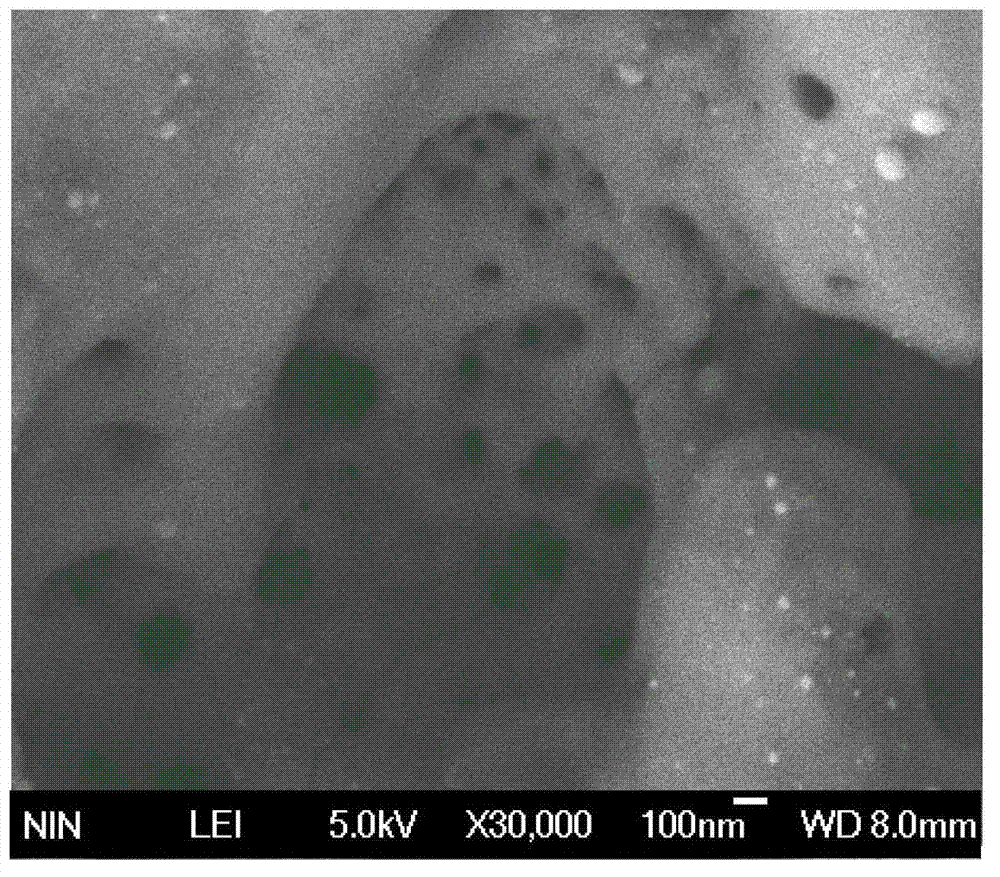

[0032] Step 2, TiO 2 Nanotube pre-coating surface silver-loaded treatment:

[0033] 201. AgNO ...

Embodiment 2

[0042] Step 1. Preparation of TiO on the surface of the Ti6Al4V titanium alloy sample to be treated 2 Nanotube Precoat:

[0043] 101. Polish the surface of the medical Ti6Al4V titanium alloy sample to be treated to a mirror surface, then ultrasonically clean the polished medical Ti6Al4V titanium alloy sample with distilled water, acetone and absolute ethanol in sequence, and then clean the medical Ti6Al4V titanium alloy after ultrasonic cleaning with absolute ethanol. Alloy samples were dried in vacuum;

[0044] 102. Completely immerse the medical Ti6Al4V titanium alloy sample after vacuum drying in 101 in the ethylene glycol aqueous solution containing KF, and perform anodic oxidation treatment under 30V constant potential condition for 1h; the ethylene glycol aqueous solution containing KF The mass concentration of alcohol is 85%, the mass concentration of KF is 5%, and the balance is water;

[0045] Step 2, TiO 2 Nanotube pre-coating surface silver-loaded treatment:

[...

Embodiment 3

[0055] Step 1. Preparation of TiO on the surface of the Ti6Al7Nb titanium alloy sample to be treated 2 Nanotube Precoat:

[0056] 101. Polish the surface of the medical Ti6Al7Nb titanium alloy sample to be treated to a mirror surface, then ultrasonically clean the polished medical Ti6Al7Nb titanium alloy sample with distilled water, acetone and absolute ethanol in sequence, and then clean the medical Ti6Al7Nb titanium alloy after ultrasonic cleaning with absolute ethanol Alloy samples were dried in vacuum;

[0057] 102. Completely immerse the medical Ti6Al7Nb titanium alloy sample after vacuum drying in 101 in the 4 In the ethylene glycol aqueous solution of F and KF, under the condition of 40V constant potential, anodic oxidation treatment 4h; Said containing NH 4 The mass concentration of ethylene glycol in the ethylene glycol aqueous solution of F and KF is 90%, NH 4 The mass concentration of F is 2.5%, the mass concentration of KF is 2.5%, and the balance is water;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com