Micro-arc oxidation electrolyte and micro-arc oxidation method

A micro-arc oxidation and electrolyte technology, applied in electrolytic coatings, anodic oxidation, surface reaction electrolytic coatings, etc., can solve the problems of cumbersome process and achieve the effect of simple process, easy control and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

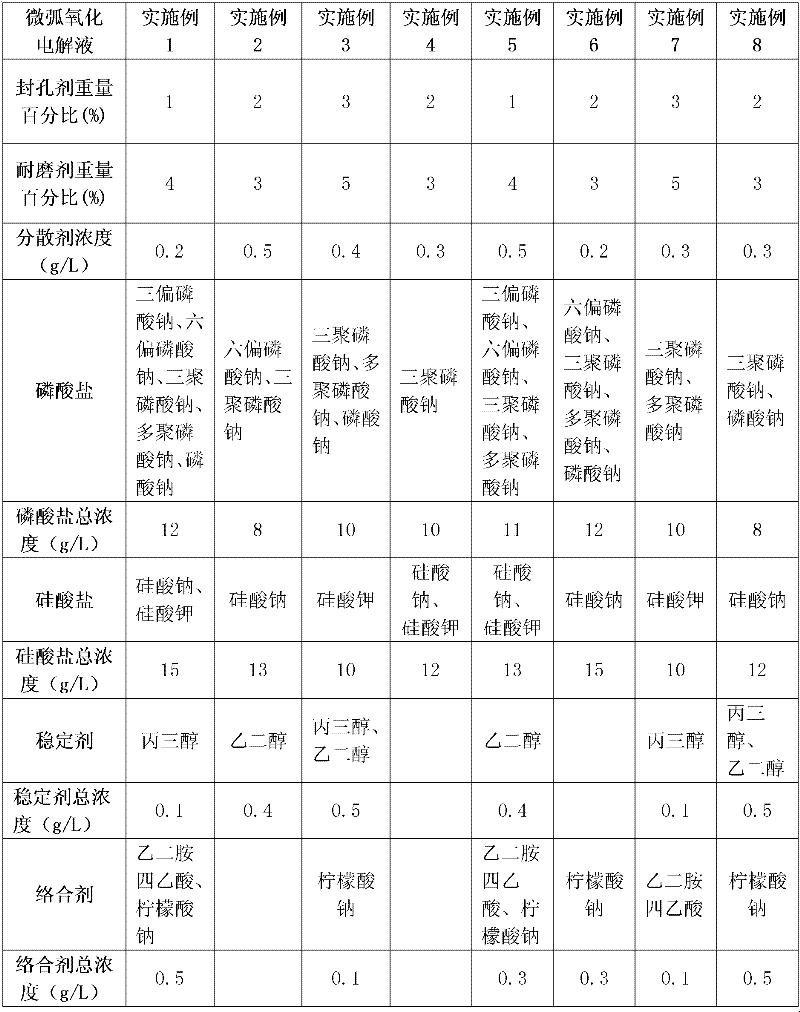

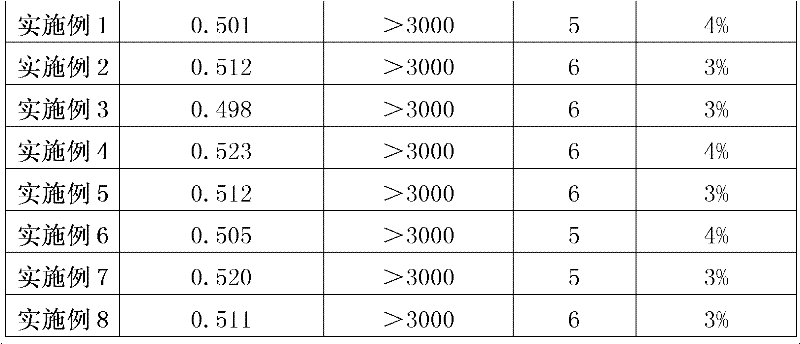

Embodiment 1

[0022] Wear-resistant agent, sealing agent and dispersant are added to the base solution with a pH of 8 at the same time. After adding, ultrasonically vibrate for 20 minutes, and then immerse the parts to be plated made of magnesium alloy in the electrolytic tank filled with micro-arc oxidation electrolyte. The piece to be plated is used as the anode, and the stainless steel plate is used as the cathode. The reaction time is 5 minutes, the electrolyte temperature is 15°C, and the current density is 5A / dm 2 The micro-arc oxidation is carried out under the micro-arc oxidation process with a voltage of 150V, so that a dense micro-arc oxidation film is formed on the surface of the workpiece to be plated. The composition of the micro-arc oxidation electrolyte is shown in Table 1. The obtained micro-arc oxidation The arc oxidation film was tested for performance, and the results are shown in Table 2.

Embodiment 2

[0024] Wear-resistant agent, sealing agent and dispersant are added to the base solution with a pH of 10 at the same time. After adding, ultrasonically vibrate for 25 minutes, and then immerse the piece to be plated made of magnesium alloy in the electrolytic cell filled with the micro-arc oxidation electrolyte. The piece to be plated is used as the anode, and the stainless steel plate is used as the cathode. The reaction time is 25 minutes, the electrolyte temperature is 35°C, and the current density is 12A / dm 2 The micro-arc oxidation is carried out under the micro-arc oxidation process condition with a voltage of 300V, so that a dense micro-arc oxidation film is formed on the surface of the workpiece to be plated. The composition of the micro-arc oxidation electrolyte is shown in Table 1. The obtained micro-arc oxidation The arc oxidation film was tested for performance, and the results are shown in Table 2.

Embodiment 3

[0026] Wear-resistant agent, sealing agent and dispersant are added to the base solution with a pH of 12 at the same time. After adding, ultrasonic vibration is performed for 30 minutes, and then the parts to be plated made of magnesium alloy are immersed in the electrolytic tank filled with micro-arc oxidation electrolyte. The piece to be plated is used as the anode, and the stainless steel plate is used as the cathode. The reaction time is 30 minutes, the electrolyte temperature is 40°C, and the current density is 15A / dm 2 , and the voltage is 550V under the micro-arc oxidation process conditions to carry out micro-arc oxidation, so that a layer of dense micro-arc oxidation film is formed on the surface of the workpiece to be plated. The composition of the micro-arc oxidation electrolyte is shown in Table 1. The obtained micro-arc oxidation The arc oxidation film was tested for performance, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com