Impedance compound muffler

A muffler and composite technology, applied in the direction of mufflers, machines/engines, mechanical equipment, etc., can solve problems such as discounted aerodynamic performance, polluted environment, complex structural design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

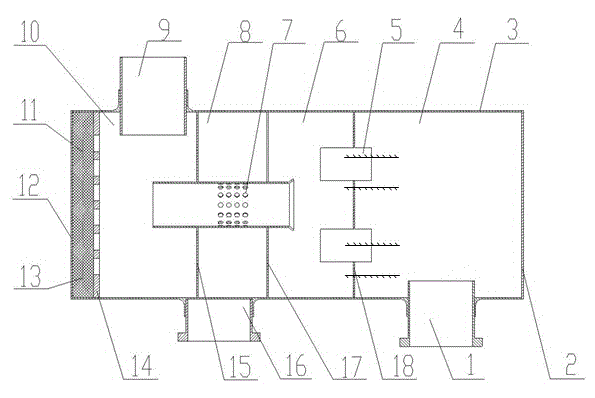

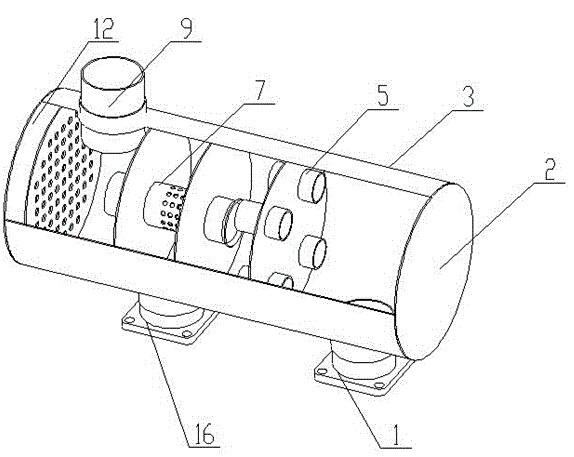

[0017] Such as figure 1 As shown, an impedance compound muffler of the present invention includes a cavity structure composed of a housing 3, a front end cover 12 and a rear end cover 2, and the cavity structure is divided into The first chamber 4, the second chamber 6, the third chamber 8 and the fourth chamber 10; the first chamber 4 is arranged with the inlet pipe 1; the fourth chamber 10 is arranged with the outlet pipe 9; on the partition I18 A plurality of insertion tubes 5 are provided to communicate with the first chamber 4 and the second chamber 6; a perforated tube 7 is fixed on the partition II17 and the partition III15, the inlet of the perforated tube 7 is located in the second chamber 6, and the outlet is located in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com