Particle filter and method for the purification of an exhaust-gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

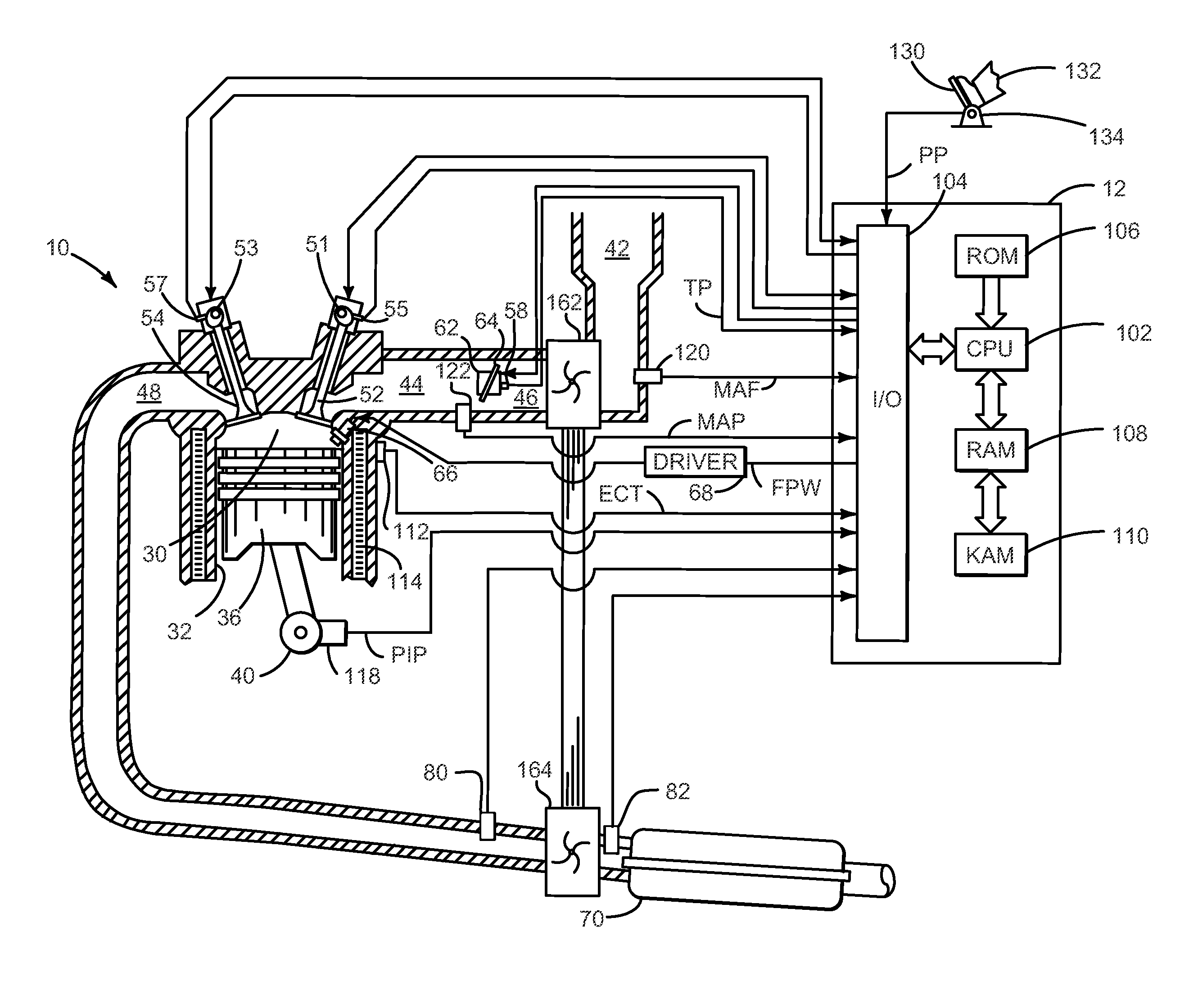

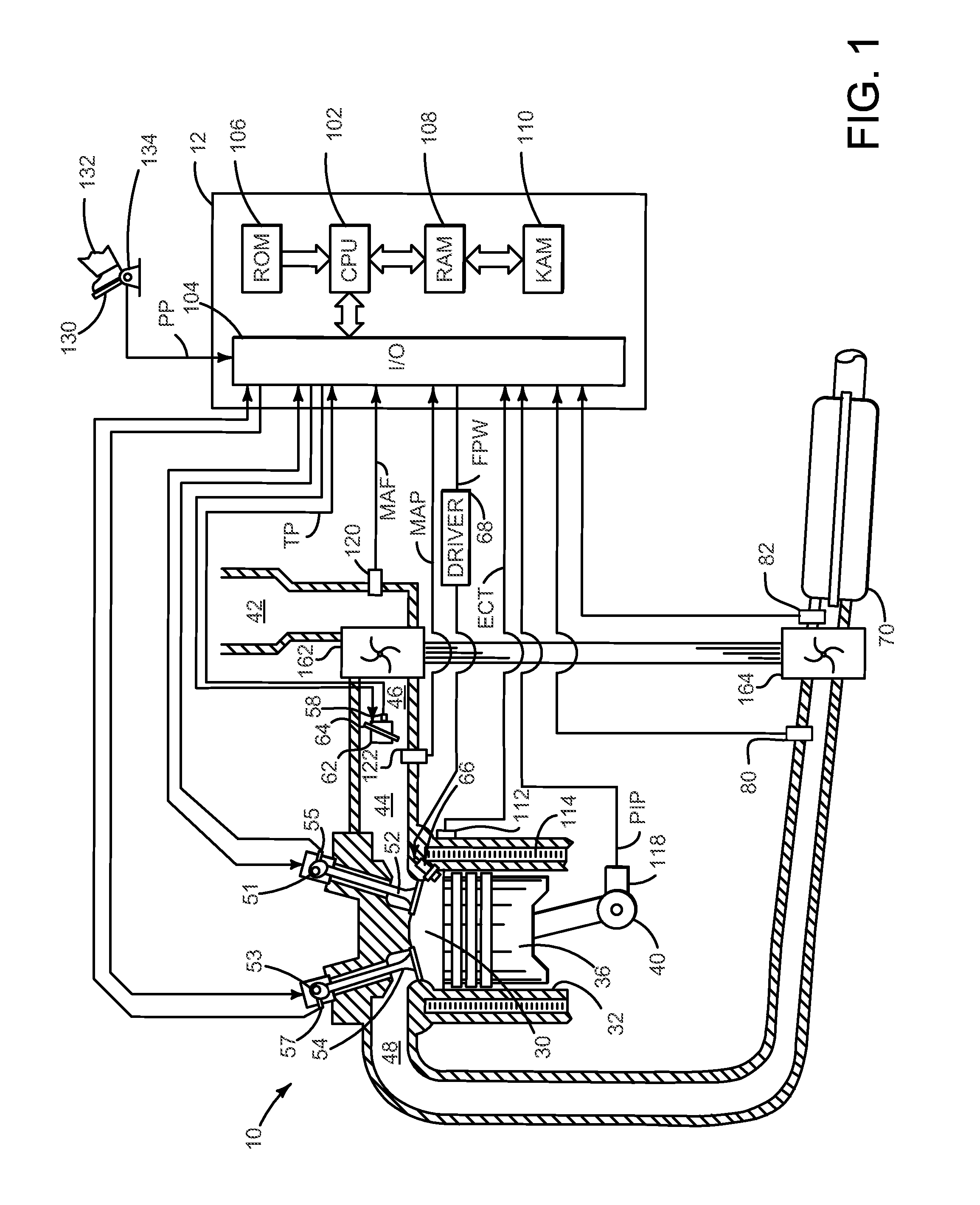

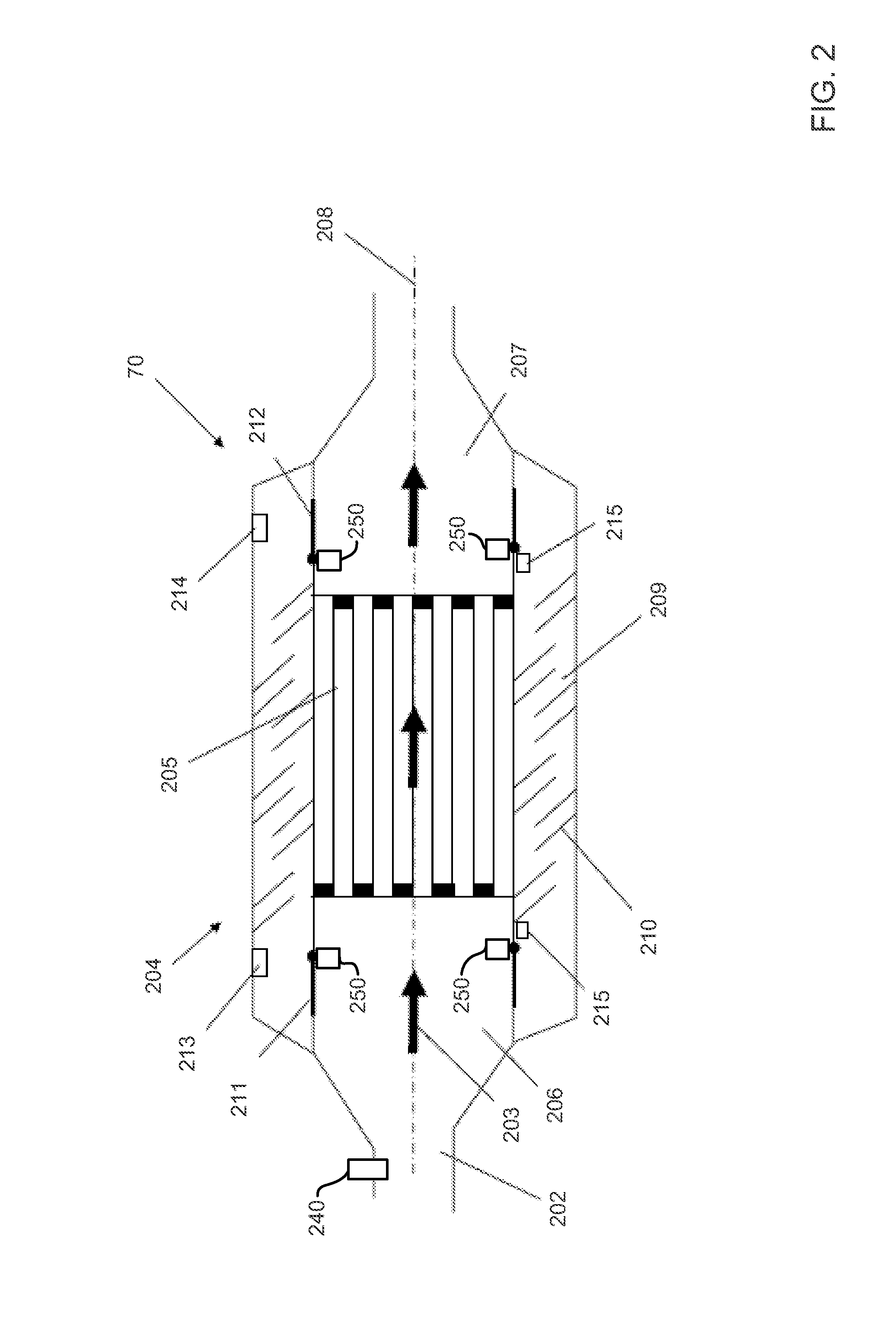

[0017]The present description is related to operating an engine that directs exhaust gas to a particulate filter. In one non-limiting example, the engine may be configured as illustrated in FIG. 1. FIGS. 2 and 3 provide a detailed view of two particulate filters and an exhaust gas routing system that directs exhaust gas through the two particulate filters. Exhaust gases may flow substantially solely through the first particulate filter as is shown in FIG. 2 when particulate matter stored in the first particulate filter is less than a threshold amount. Exhaust gases may flow through the second particulate filter as is shown in FIG. 3 when particulate matter stored in the first particulate filter is greater than the threshold amount. FIG. 4 provides a method for operating an engine and purifying engine exhaust gases via first and second particulate filters.

[0018]Referring to FIG. 1, internal combustion engine 10, comprising a plurality of cylinders, one cylinder of which is shown in F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com