Twin scroll turbocharger device with bypass

A turbocharger and vortex technology, applied in the direction of machines/engines, stators, engine components, etc., can solve problems such as leakage, increased resistance, and decreased efficiency of internal combustion engines, so as to offset compressor surge and increase energy utilization. , the effect of increasing the overall internal combustion engine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

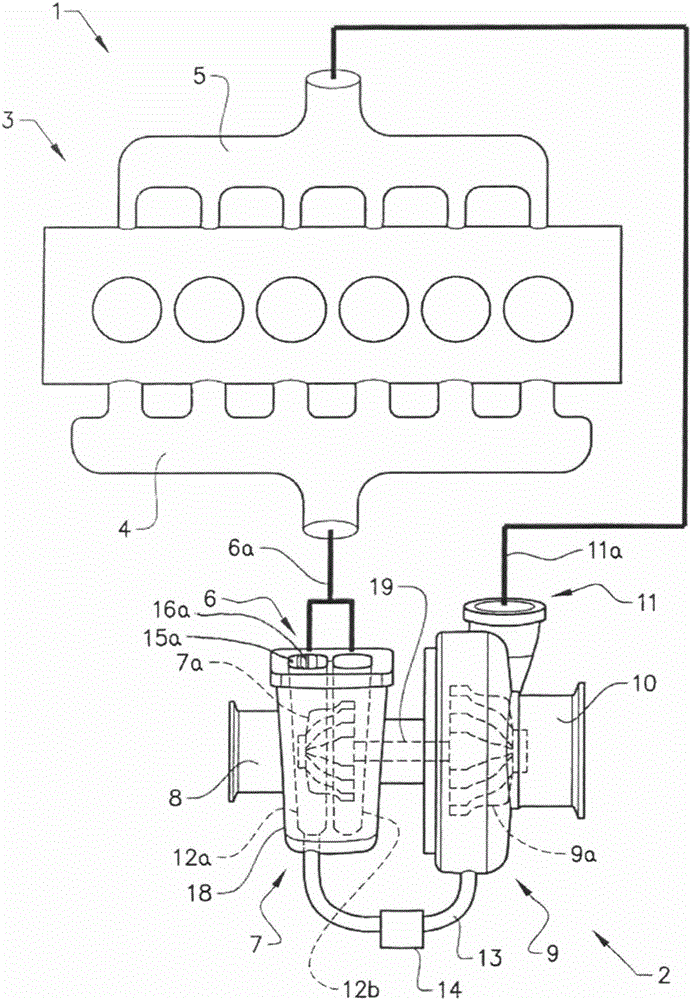

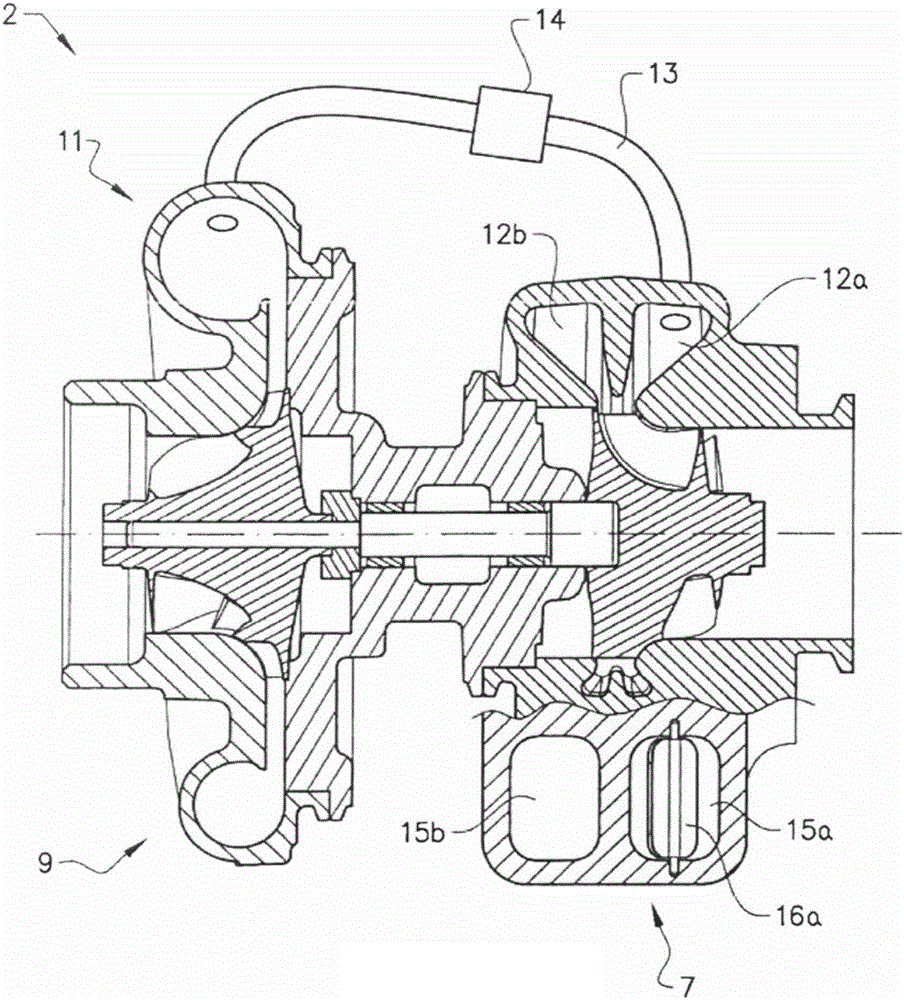

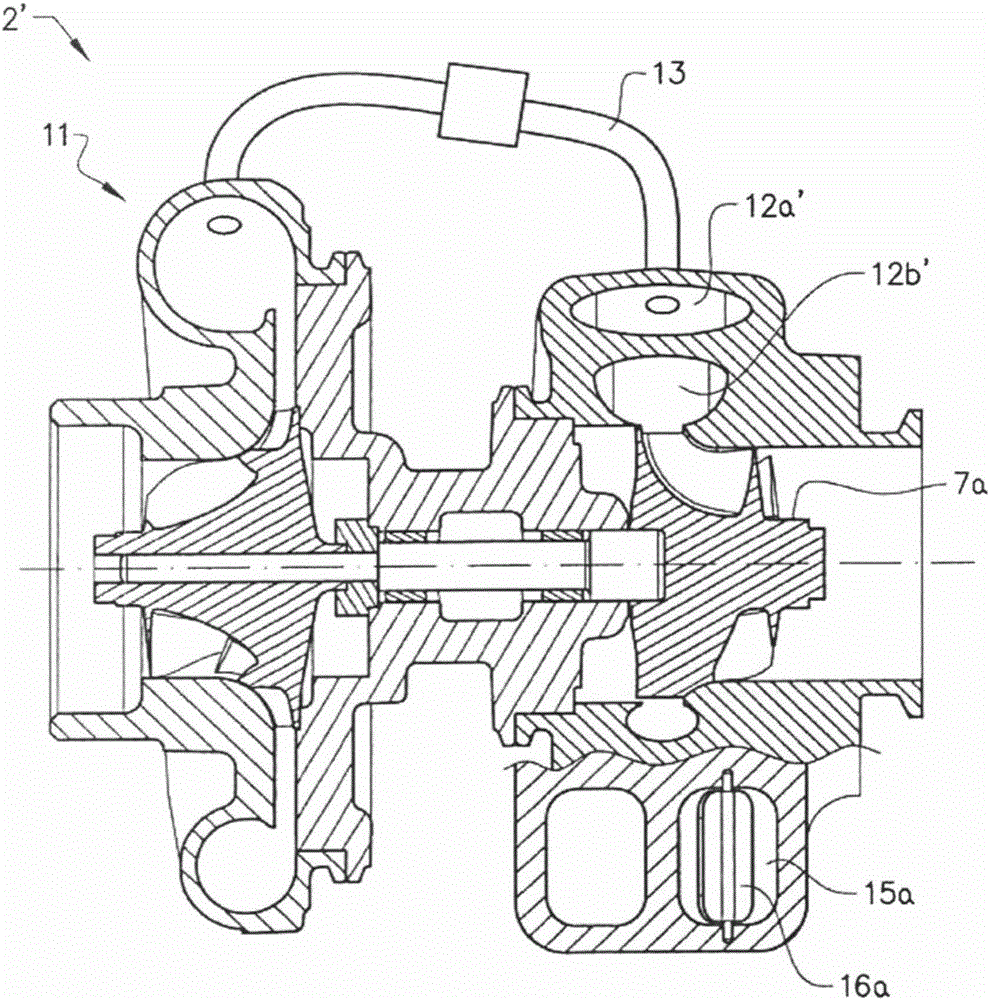

[0091] figure 1 An exemplary engine arrangement 1 comprising an internal combustion engine 3 provided with an exemplary twin-scroll turbocharger arrangement 2 according to the invention is disclosed. The internal combustion engine 3 comprises an exhaust manifold 4 and an intake manifold 5, wherein exhaust gas from the internal combustion engine 3 is expelled from the exhaust manifold into a turbine inlet 6 via one or more ducts 6a. The exhaust gas drives the turbine wheel 7 a of the turbine 7 of the twin-scroll turbocharger arrangement 2 and is then discharged through the turbine outlet 8 . The turbine wheel 7 a is connected to a compressor wheel 9 a of the compressor 9 via a shaft 19 . The twin-scroll turbocharger device 2 is enclosed by a turbocharger casing 18 .

[0092] The compressor is supplied with compressor gas, preferably ambient air, from the compressor inlet 10 . The compressed gas is compressed within the compressor 9 and then discharged from the compressor 9 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com