SCR reprocessing piping device of large-duty engine

An engine and large-displacement technology, applied to exhaust devices, engine components, combustion engines, etc., can solve problems such as low uniformity, decomposition and release of ammonia, and short reaction time between ammonia and NOx compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

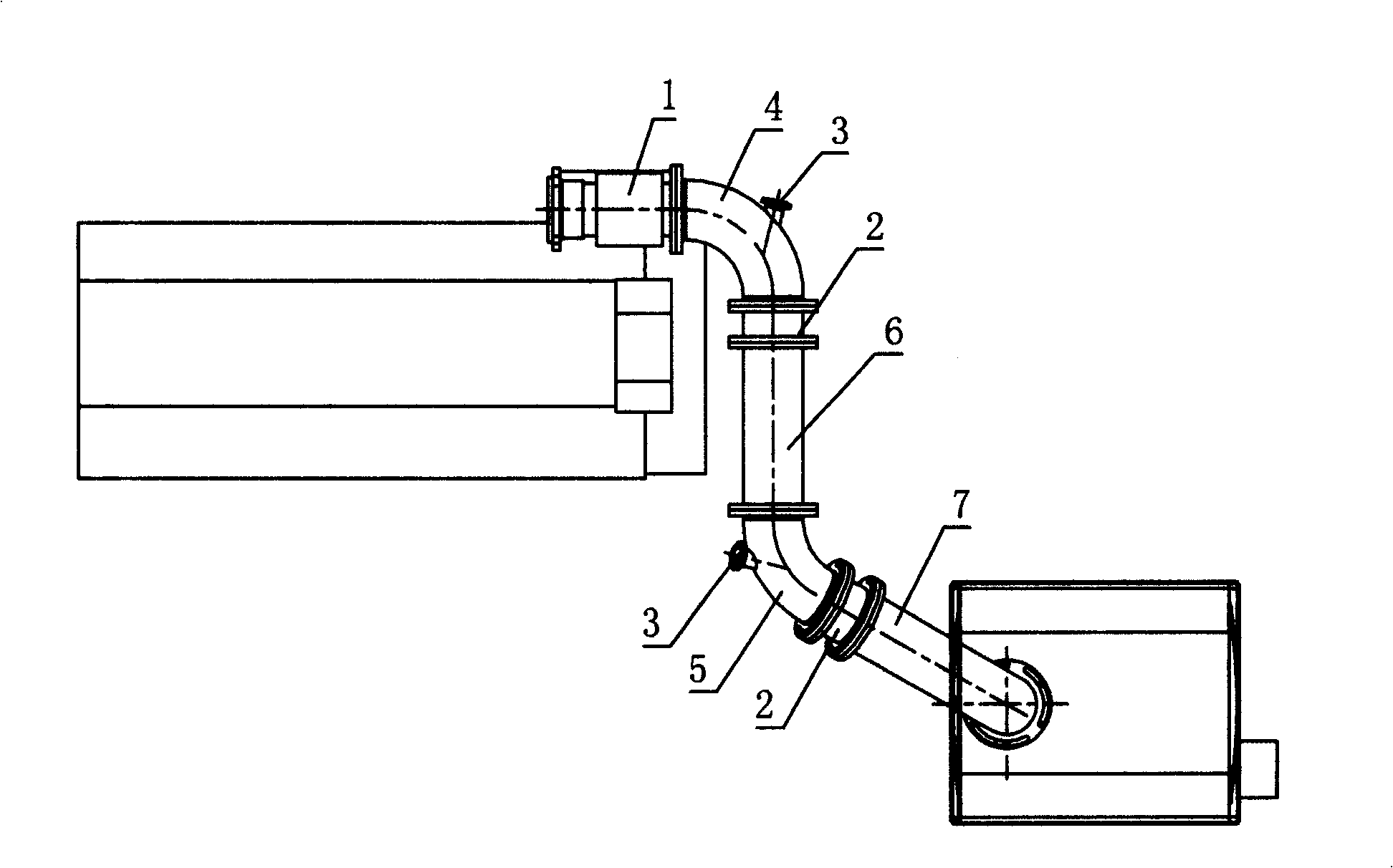

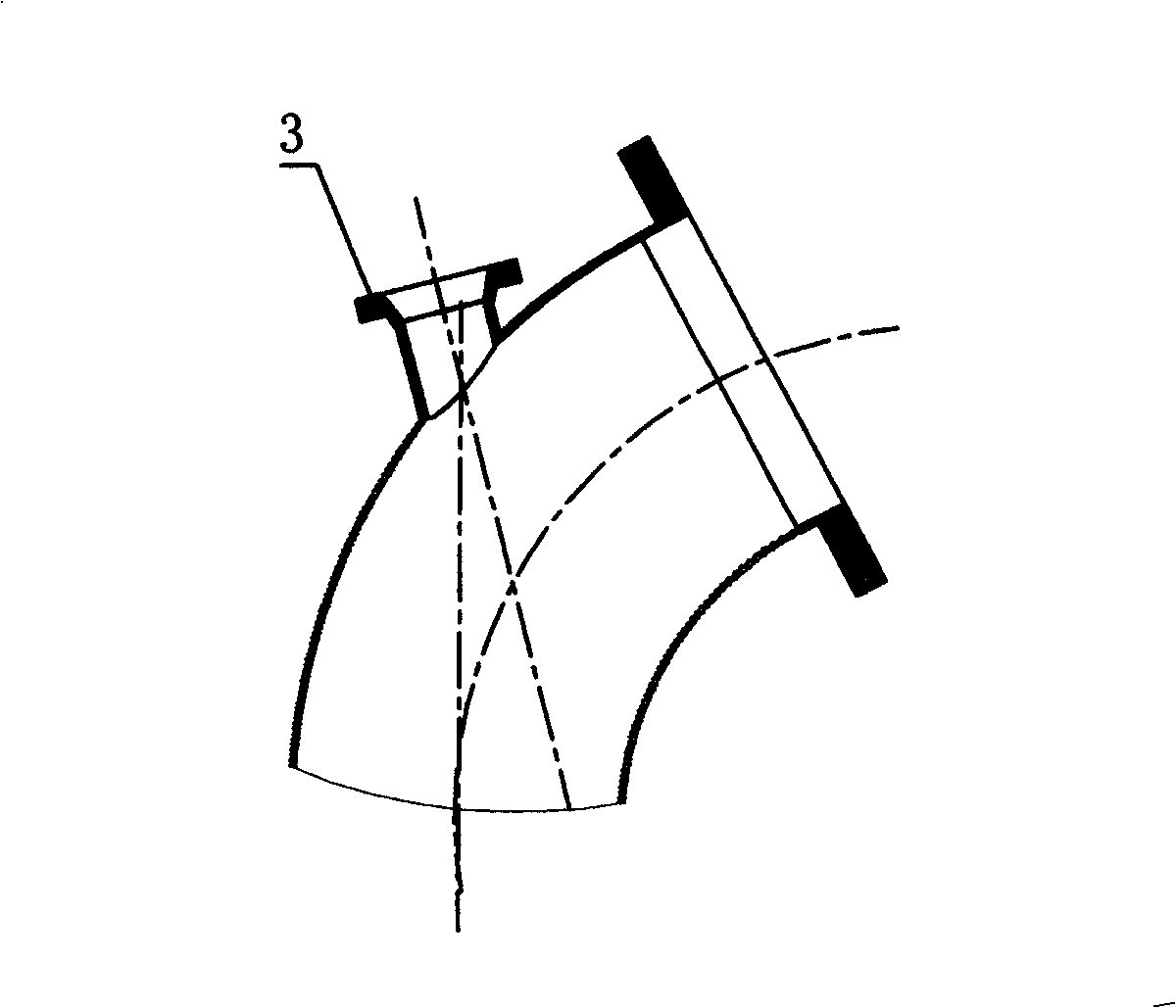

[0015] Such as figure 1 As shown, the SCR post-treatment pipeline device of a large-displacement engine is arranged on the exhaust gas discharge pipeline of the engine to effectively remove NOx compounds and other harmful substances contained in the exhaust gas, which includes a set between the engine and the SCR after-treatment device The injection pipeline is equipped with at least one nozzle 3 that can spray urea solution into the injection pipeline. The nozzle 3 is installed on the injection pipeline in such a way that the injection direction follows the flow direction of the smoke in the injection pipeline, and the nozzle 3 The injection axis forms an included angle with the axis of the injection pipeline located in its injection direction. In the injection pipeline, a mixer 2 is respectively arranged on the injection direction of the nozzle 3. The mixer 2 can be provided with a sieve in the injection pipeline. It is in the form of a sieve with holes, and the sieve on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com