Winter, summer bi service heat pump apparatus of air source

An air source heat pump technology for both winter and summer, which is applied in the field of winter and summer air source heat pump devices. It can solve the problems affecting the normal operation of the heat pump device and the performance degradation of the heat pump device, so as to reduce energy consumption, reduce throttling loss and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

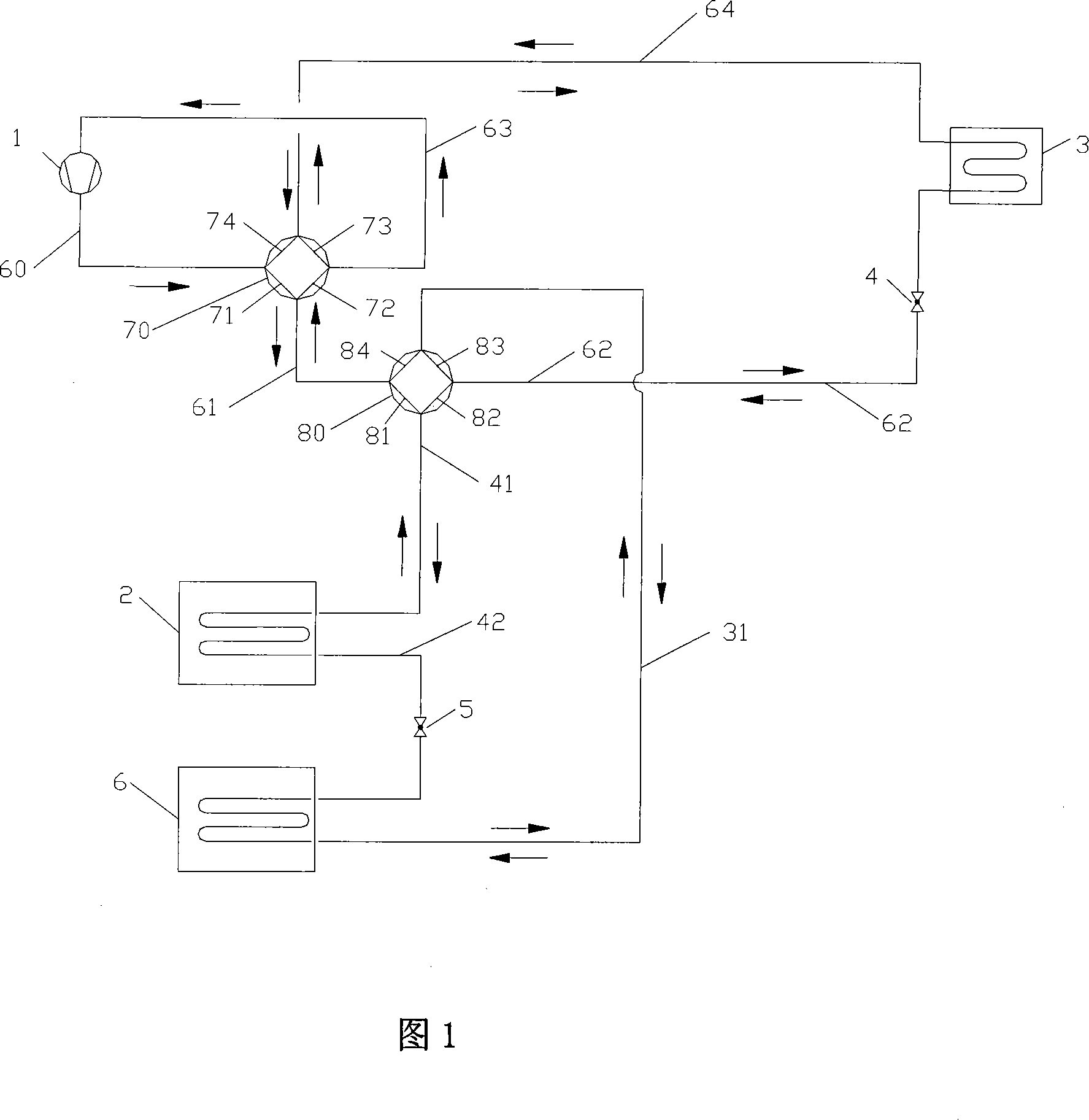

[0023] As shown in Figure 1, the whole device includes the following equipment: compressor 1, outdoor heat exchanger 2, user side heat exchanger 3, throttling mechanism (4, 5), outdoor second heat exchanger 6, four-way Valves (70, 80).

[0024] The four-way valve 70 is provided with four channels 71, 72, 73, 74, and the four-way valve 80 is also provided with four channels 81, 82, 83, 84; the user-side heat exchanger 3 can be a refrigerant-air heat exchanger , can also be a refrigerant-water heat exchanger; the outdoor heat exchanger 2 and the second outdoor heat exchanger 6 are refrigerant-air heat exchangers; the throttling mechanism (4, 5) is an electronic expansion valve.

[0025] The whole device can be divided into three circulation systems according to the different working processes: summer cooling cycle, winter heating cycle, and winter defrosting cycle.

[0026] 1. Summer refrigeration cycle

[0027] In the summer refrigeration cycle, the outlet of the compressor 1...

Embodiment 2

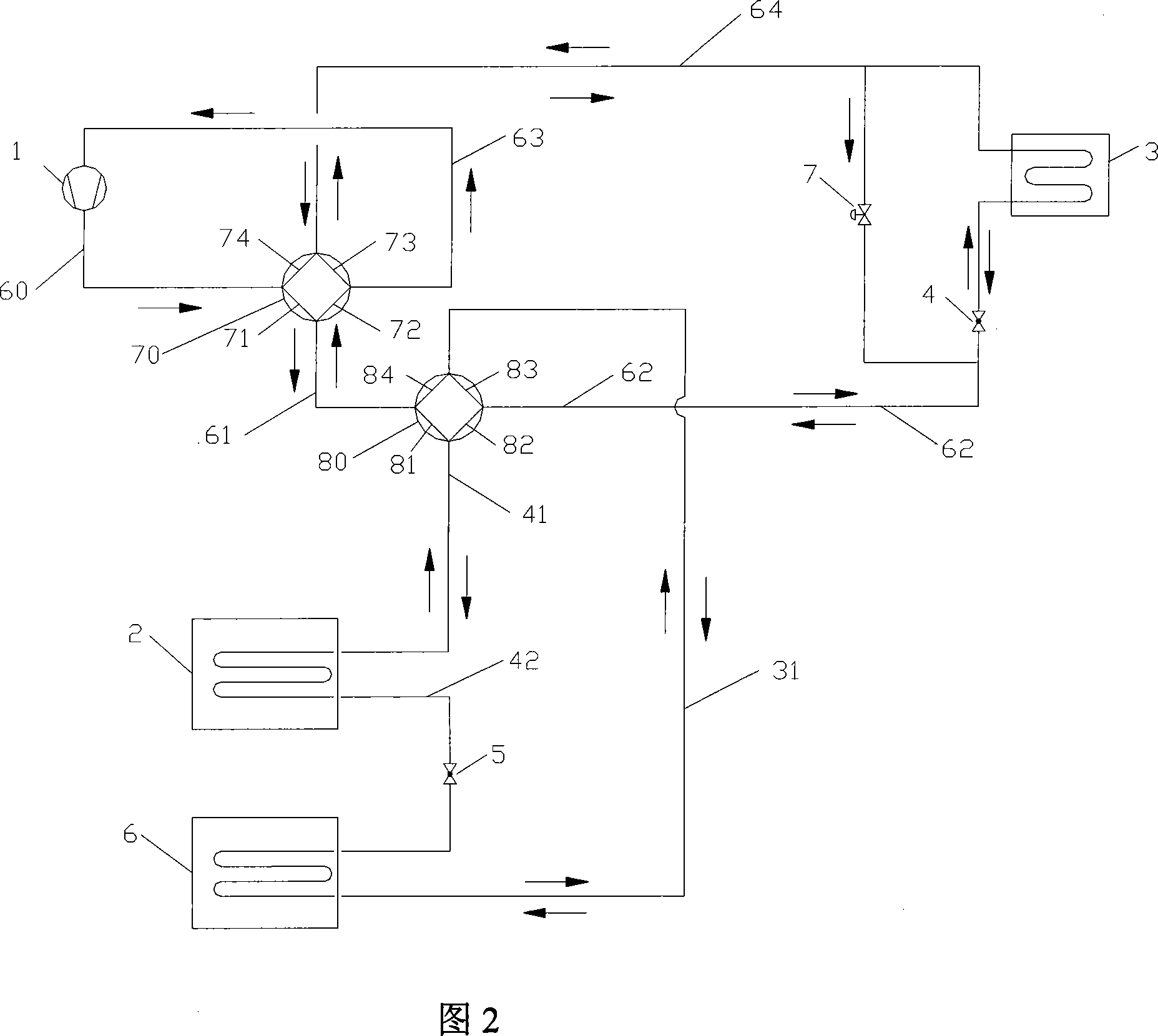

[0039] As shown in Figure 2, compared with Embodiment 1, the only difference is that the flow direction control valve 7 is added, which is connected in parallel with the user-side heat exchanger 3 and the throttling mechanism 4, while other equipment and connection methods in the device Exactly the same as Example 1.

[0040] During the working process of the cooling cycle in summer and the heating cycle in winter in embodiment 2, the flow direction control valve 7 is closed, so the working process of the cooling and heating cycle in embodiment 2 is exactly the same as that in embodiment 1.

[0041] During the working process of the winter defrosting cycle in Example 2, the flow direction control valve 7 is opened, and the throttling mechanism 4 is closed. Therefore, during the defrosting process, the refrigerant superheated vapor from the compressor 1 does not pass through the user-side heat exchanger 3 and the throttling mechanism 4, and bypass the flow control valve 7, so t...

Embodiment 3

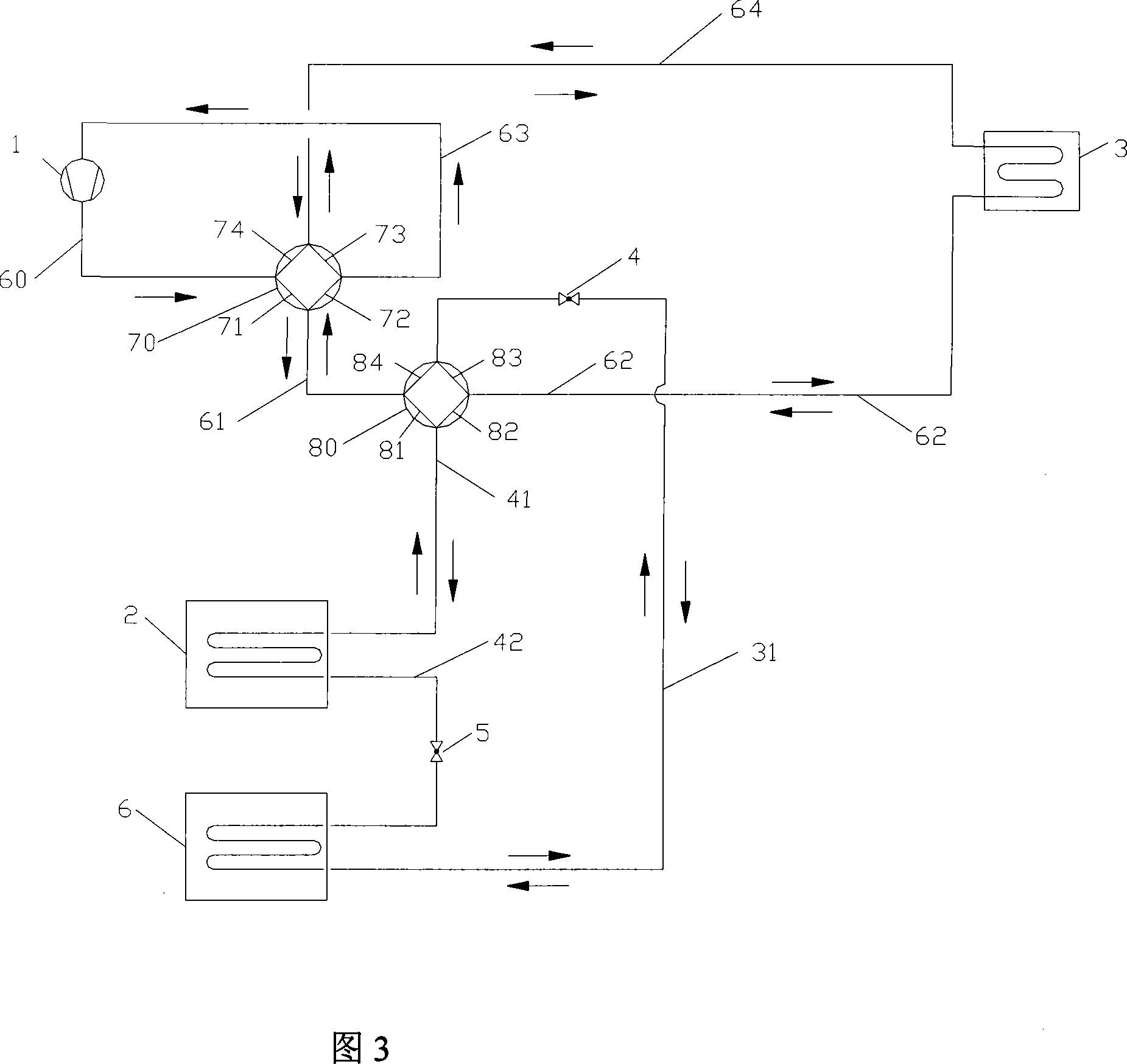

[0044] As shown in Figure 3, the difference between it and Embodiment 1 is: in Embodiment 1, the throttling mechanism 4 is arranged on the pipe connecting the user-side heat exchanger 3 and the four-way valve 80; but in Embodiment 3 , the throttling mechanism 4 is set on the pipeline connecting the second outdoor heat exchanger 6 and the four-way valve 80 , that is, the channel through which the outdoor second heat exchanger 6 passes through the pipeline 31 , the throttling mechanism 4 and the four-way valve 80 (83,84) are connected.

[0045] Apart from that, in Embodiment 3, other devices are connected in the same way as in Embodiment 1. During operation, the functions and working process of each device are also the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com