System and method of back pressure type small steam turbine driving water supply pump for power frequency electric generator speed adjustment

A technology for small steam turbines and generators, which is applied in machine/engine, pump, pump control and other directions to reduce throttling losses, increase electricity sales revenue, and improve operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

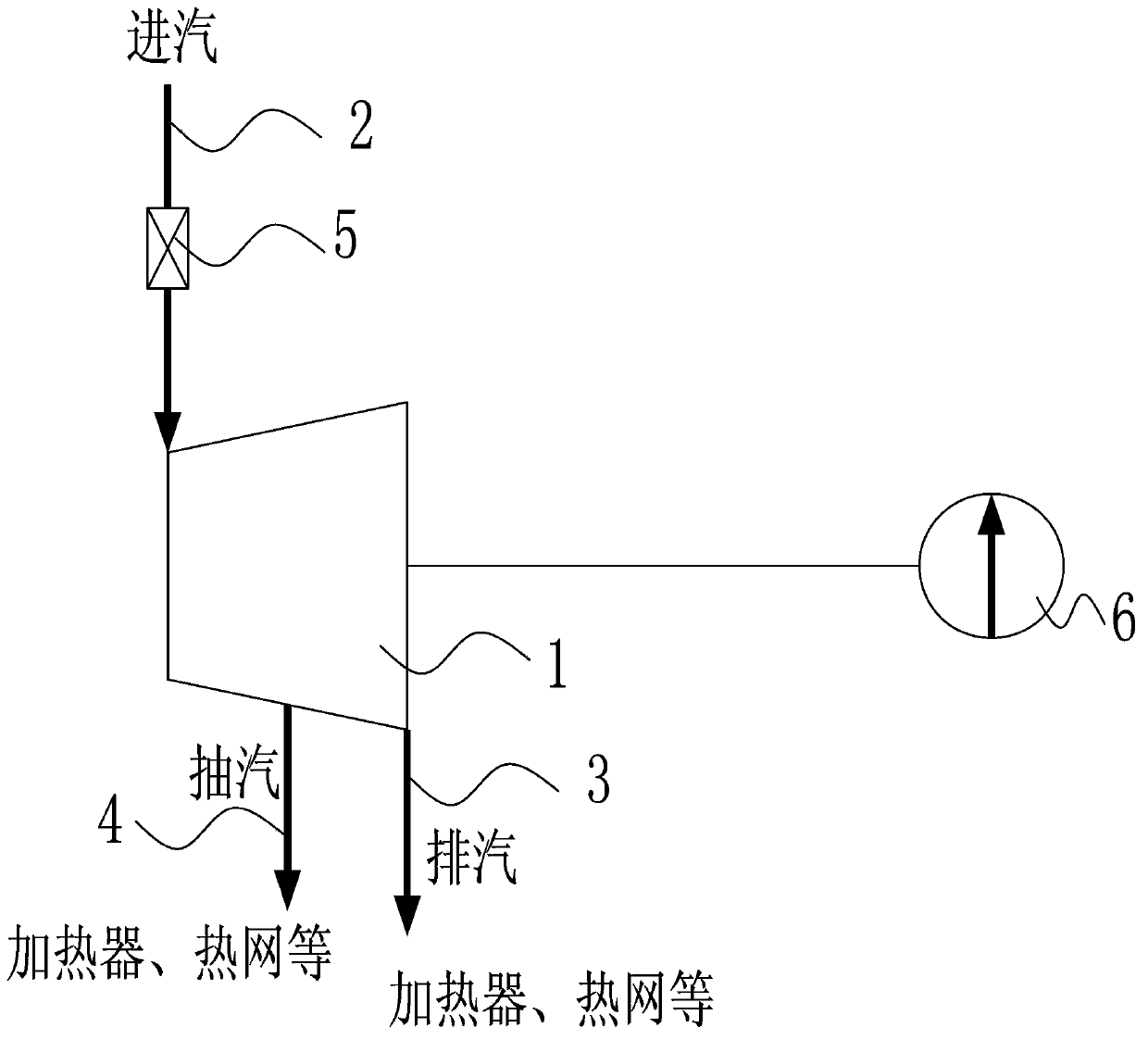

[0047] Such as Figure 4 As shown, the back-pressure small steam turbine-driven feed water pump system for power frequency generator speed regulation in this embodiment includes a small steam turbine 1, steam inlet pipeline 2, exhaust steam pipeline 3, steam extraction pipeline 4, regulating valve 5, feed water pump ( or other pumps) 6, speed control gearbox 7, power frequency generator 8, transformer 9 components. The steam inlet of the small steam turbine 1 is connected to the steam inlet pipeline 2, and the steam in the steam inlet pipeline comes from the high-pressure steam of the thermal system of the generating set, and the steam exhaust port of the small steam turbine 1 is connected to the exhaust steam pipeline 3, and the steam exhaust pipeline is connected to a low-temperature heat source ( Low pressure steam source) heater or heat exchanger (not shown in the figure) connection. A regulating valve 5 is installed at the steam inlet pipe to adjust the steam flow rate o...

Embodiment 2

[0055] Such as Figure 5 As shown, the difference between the back-pressure small steam turbine-driven feed pump system of this embodiment and the system of Embodiment 1 is that:

[0056] The feed water pump 6 and the industrial frequency generator 8 are located at the same shaft end of the small steam turbine 1, the input end of the feed water pump 6 is connected with the shaft end of the small steam turbine 1, the output end of the feed water pump 6 is connected with the input end of the speed regulating gear box 7, The output end of the speed regulating gearbox 7 is coaxially connected with the input end of the power frequency generator 8 . The working principle of the system of this embodiment is as follows:

[0057] When the steam pushes the small steam turbine 1 to rotate, it simultaneously drags the coaxial feedwater pump 6 to rotate, and the rotation of the feedwater pump 6 drives the power frequency generator 8 to rotate and generate electricity through the adjustmen...

Embodiment 3

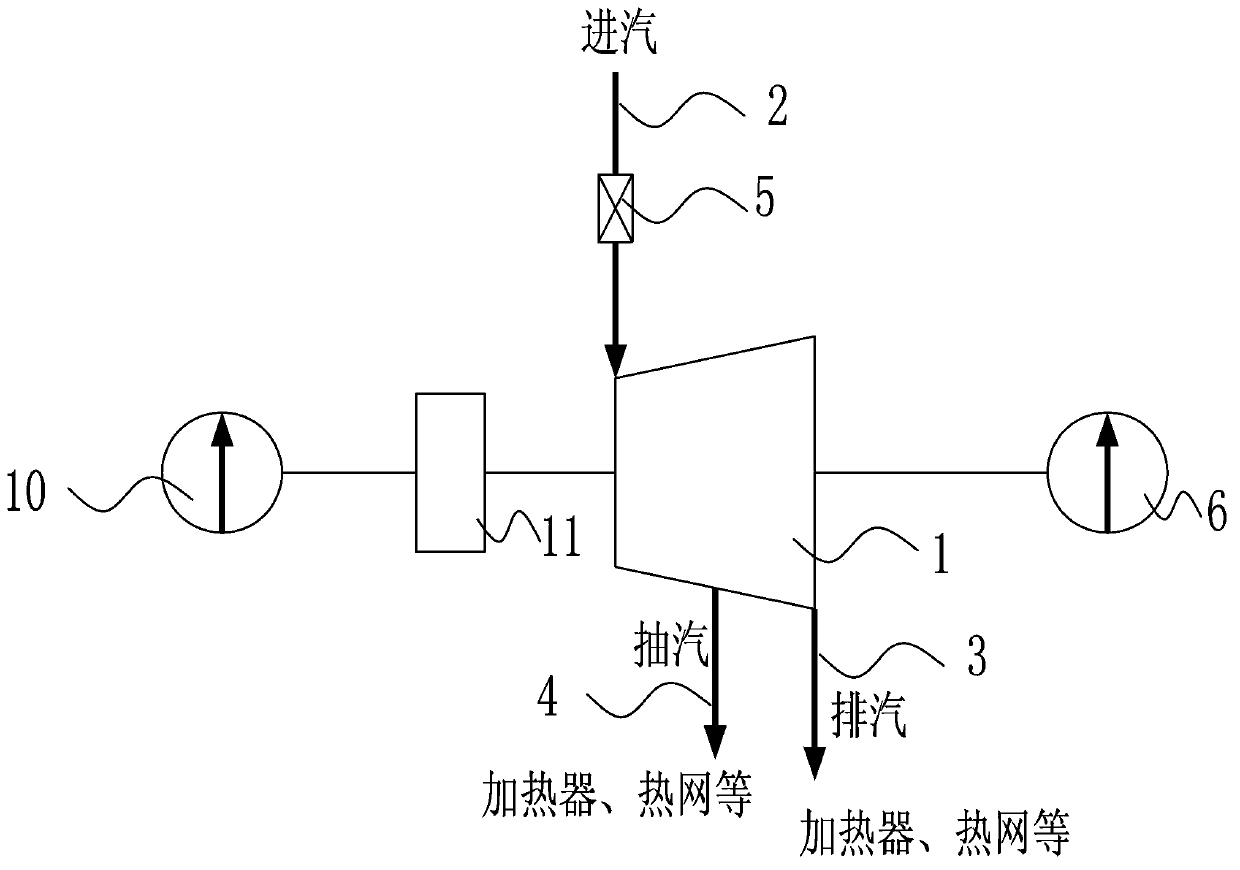

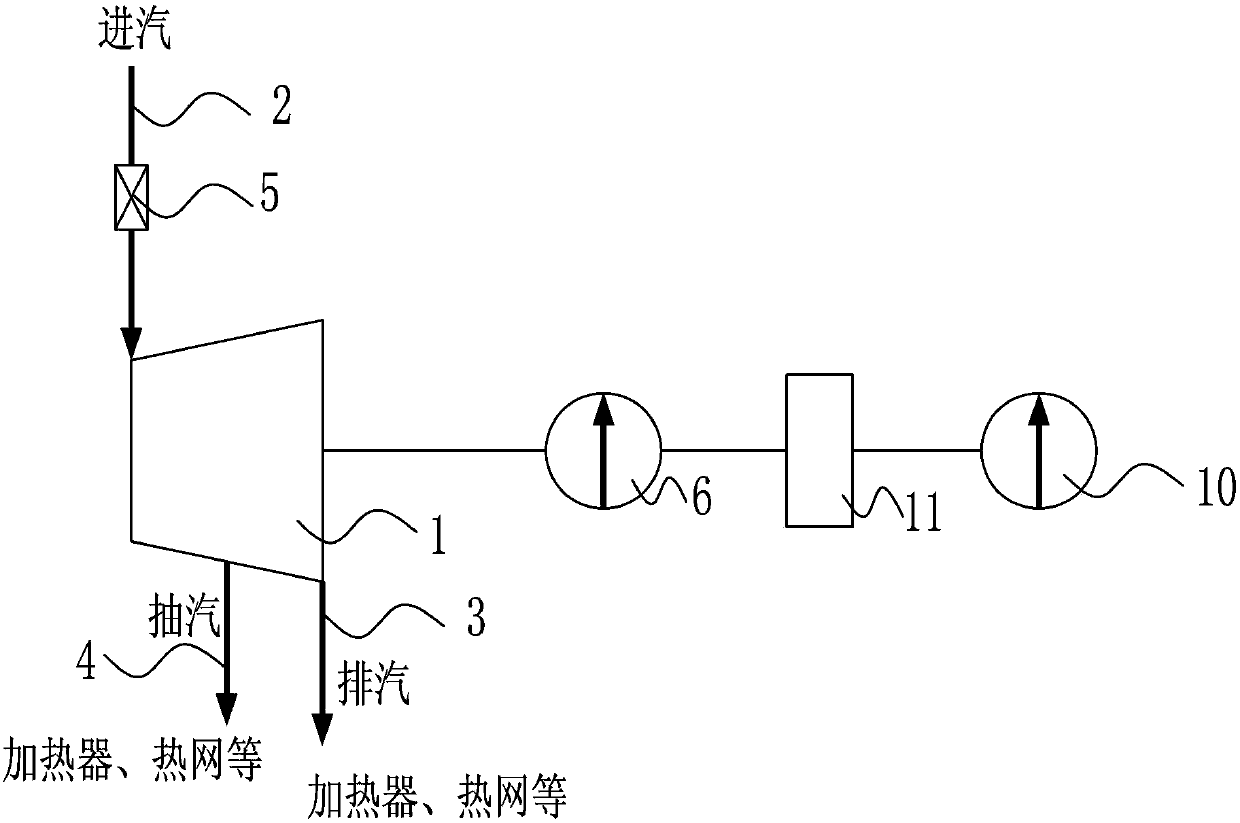

[0059] Such as Image 6 As shown, the difference between the back-pressure small steam turbine-driven feed pump system of this embodiment and the system of Embodiment 1 is that:

[0060] In this embodiment, the small steam turbine 1 drives not only a feedwater pump, but a feedwater pump set, which consists of a front pump (or other pump) 10 and a feedwater pump (or other pump) 6, And the feed water pump group is located at the same shaft end of the small steam turbine. According to the speed ratio between the front pump 10 and the feed water pump 6, a fixed speed ratio gearbox 11 is selectively installed between the front pump 10 and the feed water pump 6, and the fixed speed ratio gearbox 11 is coaxially connected with the feed water pump 6 , the constant speed ratio gearbox 11 is also coaxially connected with the front pump 10, and the input end of the constant speed ratio gearbox 11 is connected with the output end of the feed water pump 6, and the output end of the consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com