Refrigerating system using swirling flow ejector

A refrigeration system and ejector technology, which is applied in the field of refrigeration systems and refrigeration systems using vortex ejectors, can solve the problems that the expansion work has not been fully recovered and is difficult to apply on a large scale, and achieve the effect of reducing throttling loss and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following Example.

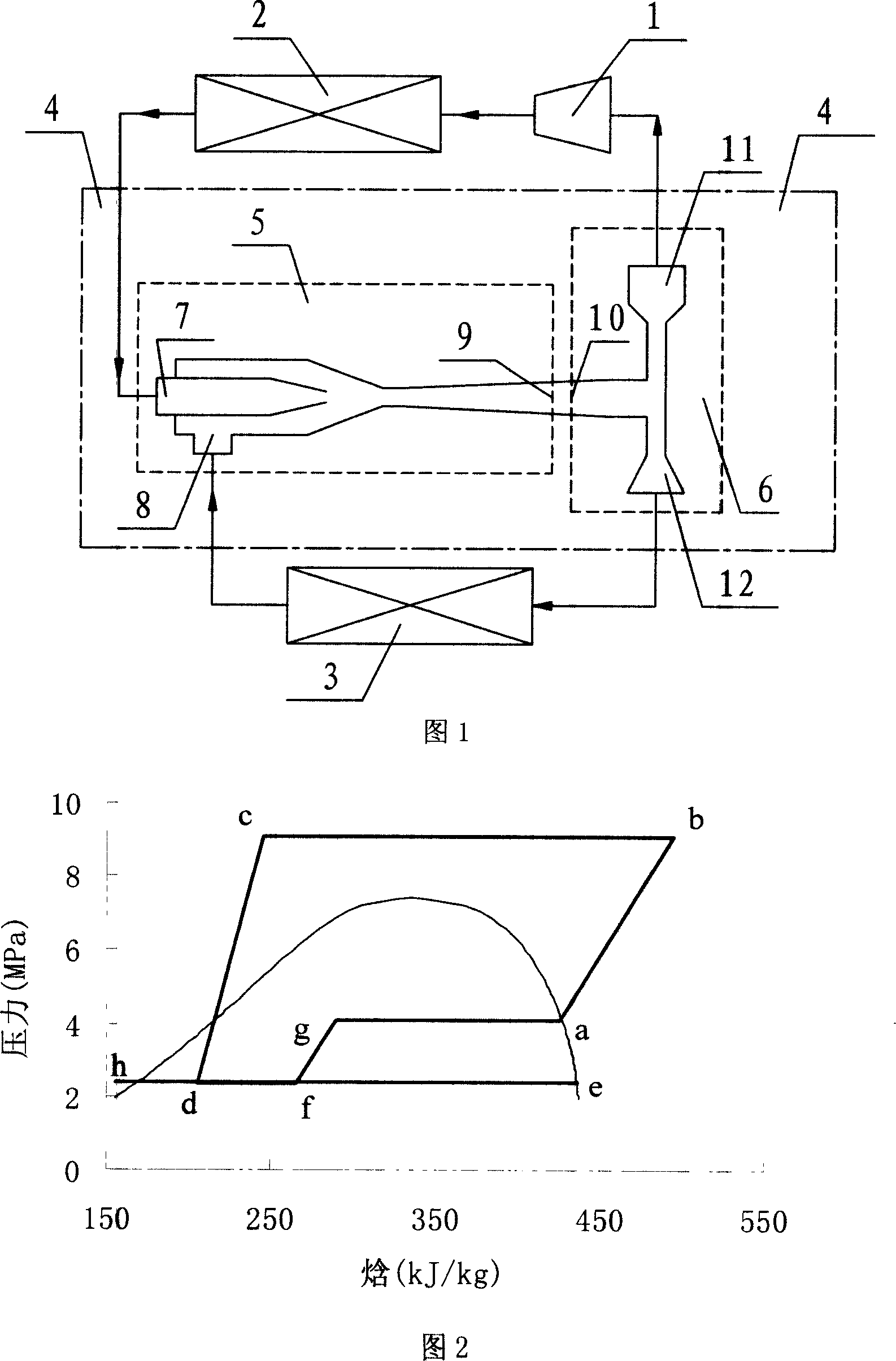

[0015] As shown in FIG. 1 , this embodiment is composed of a compressor 1 , a condenser 2 , an evaporator 3 , and a vortex injector 4 , and the vortex injector 4 is the part included in the dotted line box in FIG. 1 . The outlet of compressor 1 is connected to the inlet of condenser 2, the outlet of condenser 2 is connected to the nozzle 7 of vortex injector 4, the outlet 11 of the high-temperature end of the vortex tube of vortex injector 4 is connected to the inlet of compressor 1, and the vortex tube of vortex injector 4 The outlet 12 of the low temperature end is connected with the inlet of the eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com