Backpressure machine acting and heat supply device for steam exhaust heat supply network of intermediate pressure cylinder of steam turbine

A heating device, steam turbine technology, applied in steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as inability to realize, inability to realize coaxial driving of power equipment, inability to realize power output of back pressure machines, etc. The effect of power supply, coal consumption reduction, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

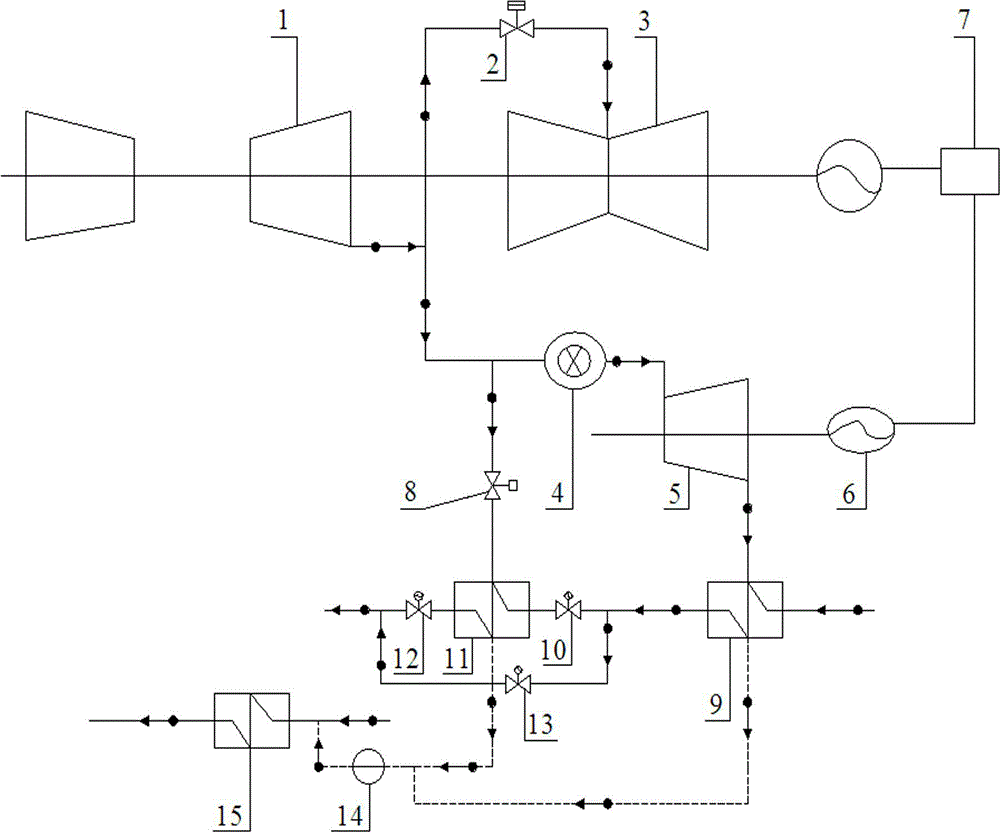

[0047] Such as figure 1 As shown, the back pressure machine power and heat supply device used for the steam turbine medium-pressure cylinder exhaust heat supply network includes the steam turbine medium-pressure cylinder 1 and the steam turbine low-pressure cylinder 3, and the exhaust port of the steam turbine medium-pressure cylinder 1 is provided with Two branch pipelines, one of which is connected to the steam inlet of the low-pressure cylinder 3 of the steam turbine, on which a butterfly valve 2 for adjusting the steam intake of the low-pressure cylinder is installed, and the power output end of the low-pressure cylinder 3 of the steam turbine is connected to the main engine The plant power system 7 is connected to each other, and the other branch pipeline of the exhaust port of the intermediate pressure cylinder 1 of the steam turbine is equipped with a back pressure machine 5 and its control equipment, and a back pressure machine 5 is installed at the steam inlet end of t...

Embodiment 2

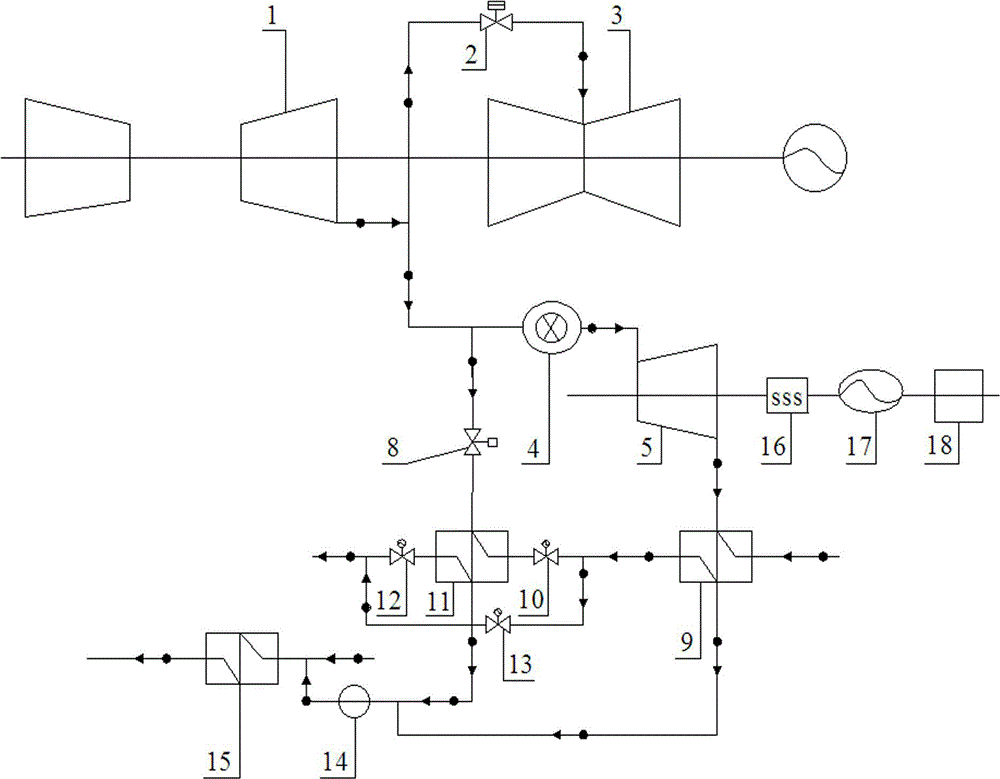

[0051] Such as figure 2 As shown, the back pressure machine power and heat supply device used for the steam turbine medium-pressure cylinder exhaust heat supply network includes the steam turbine medium-pressure cylinder 1 and the steam turbine low-pressure cylinder 3, and the exhaust port of the steam turbine medium-pressure cylinder 1 is provided with Two branch pipelines, one of which is connected to the steam inlet of the low-pressure cylinder 3 of the steam turbine, and a butterfly valve 2 for adjusting the steam inlet of the low-pressure cylinder is installed on the branch pipeline, and the other of the exhaust port of the medium-pressure cylinder 1 of the steam turbine A branch pipeline is equipped with a back pressure machine 5 and its control equipment, and the main steam valve and speed regulating valve 4 of the back pressure machine are installed at the steam inlet end of the back pressure machine 5, and the power of the back pressure machine 5 The output end is co...

Embodiment 3

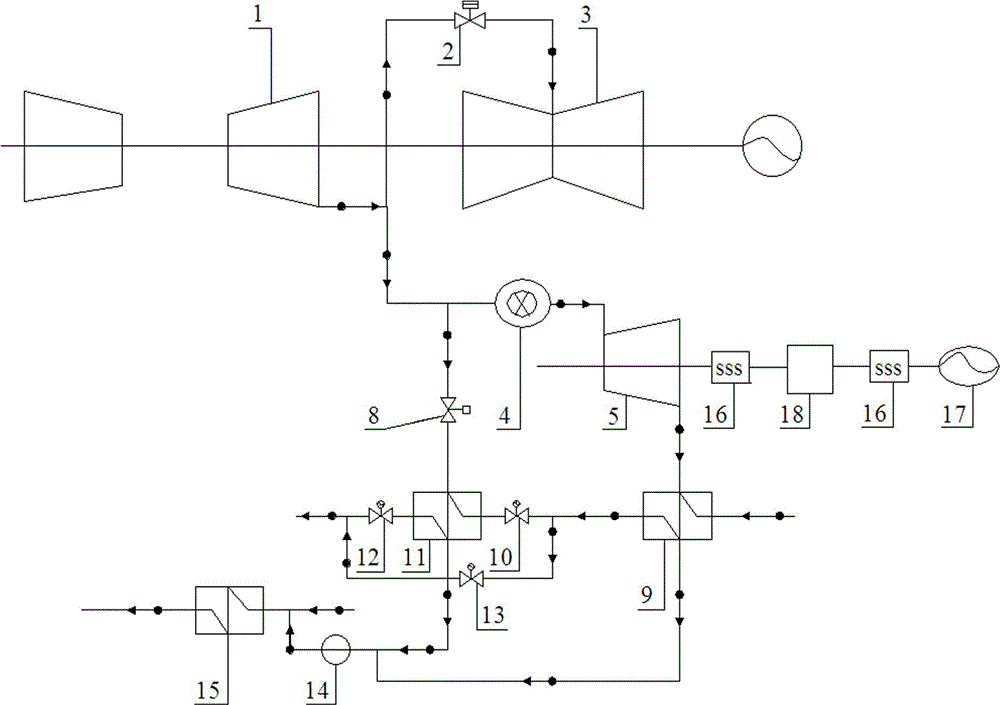

[0056] Such as image 3 As shown, the back pressure machine power and heat supply device used for the steam turbine medium-pressure cylinder exhaust heat supply network includes the steam turbine medium-pressure cylinder 1 and the steam turbine low-pressure cylinder 3, and the exhaust port of the steam turbine medium-pressure cylinder 1 is provided with Two branch pipelines, one of which is connected to the steam inlet of the low-pressure cylinder 3 of the steam turbine, and a butterfly valve 2 for adjusting the steam inlet of the low-pressure cylinder is installed on the branch pipeline, and the other of the exhaust port of the medium-pressure cylinder 1 of the steam turbine A branch pipeline is equipped with a back pressure machine 5 and its control equipment, and the main steam valve and speed regulating valve 4 of the back pressure machine are installed at the steam inlet end of the back pressure machine 5, and the power of the back pressure machine 5 The output end is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com