Digitally controlled leading type proportional flow valve

A proportional flow valve and digital control technology, which is applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve problems such as high cost, low precision, and poor oil pollution resistance, and achieve low cost and high work efficiency. Reliable, pollution-resistant results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

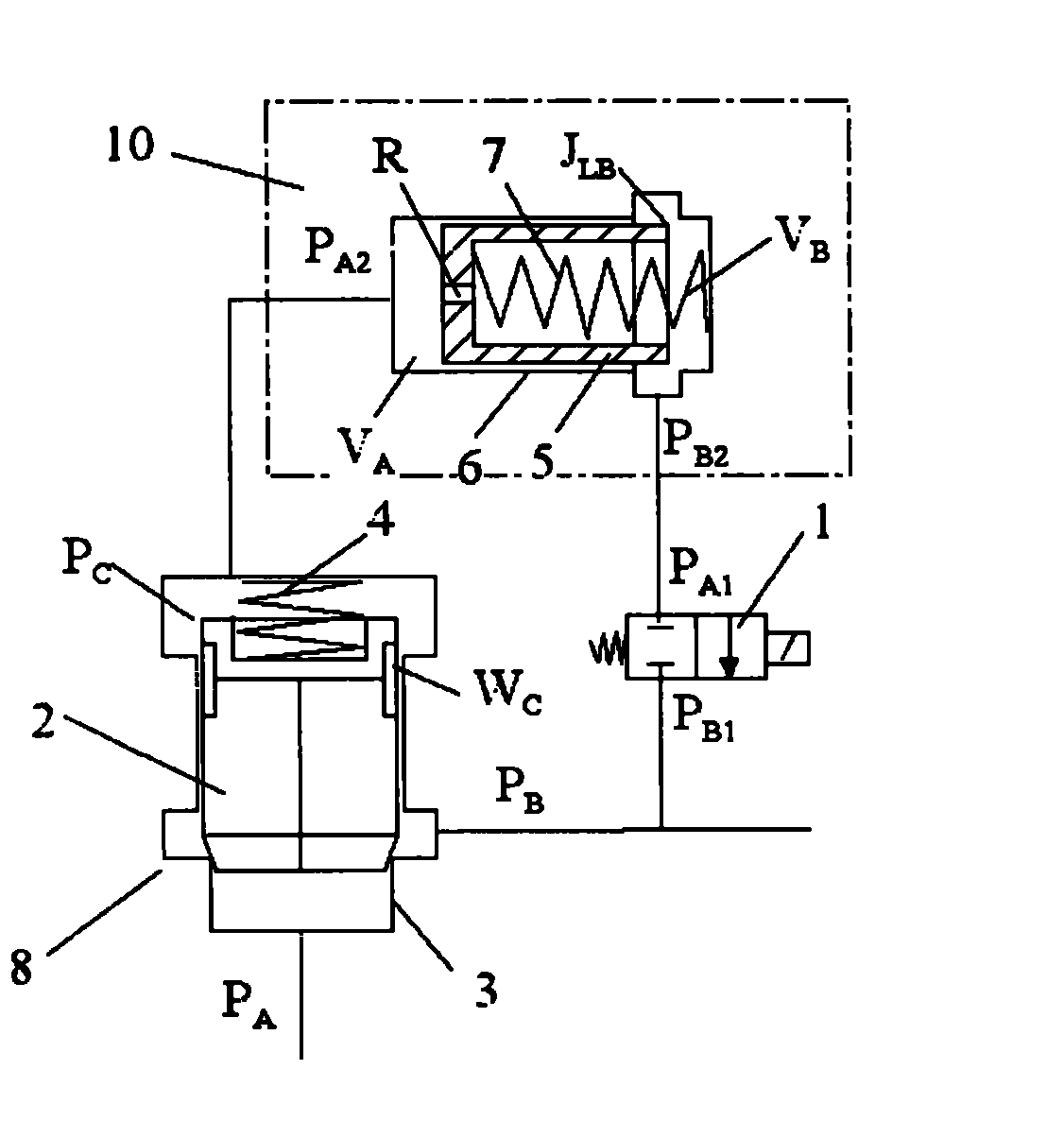

[0020] Such as figure 2 As shown, the digitally controlled pilot-operated proportional flow valve in this embodiment includes a two-position two-way high-speed switching valve 1, which consists of a main valve core 2, a main valve sleeve 3, a main valve spring 4, and a main valve oil inlet P A , main valve oil outlet P B , Main valve control chamber P C and flow feedback throttle slot W C The main valve 8 consists of: it also includes a valve core 5, a valve sleeve 6, a spring 7, a fixed orifice R, a first control chamber V A , the second control chamber V B , variable throttle edge J LB , fixed value flow meter oil inlet P A2 And fixed value flowmeter oil outlet P B2 The fixed-value flowmeter 10 constituted, the valve core 5 is arranged in the valve sleeve 6 and the bottom end of the valve core 5 and the bottom inside the valve sleeve 6 constitute the first control chamber V A , the spring 7 is installed in the second control chamber V set in the middle of the spool 5...

Embodiment 2

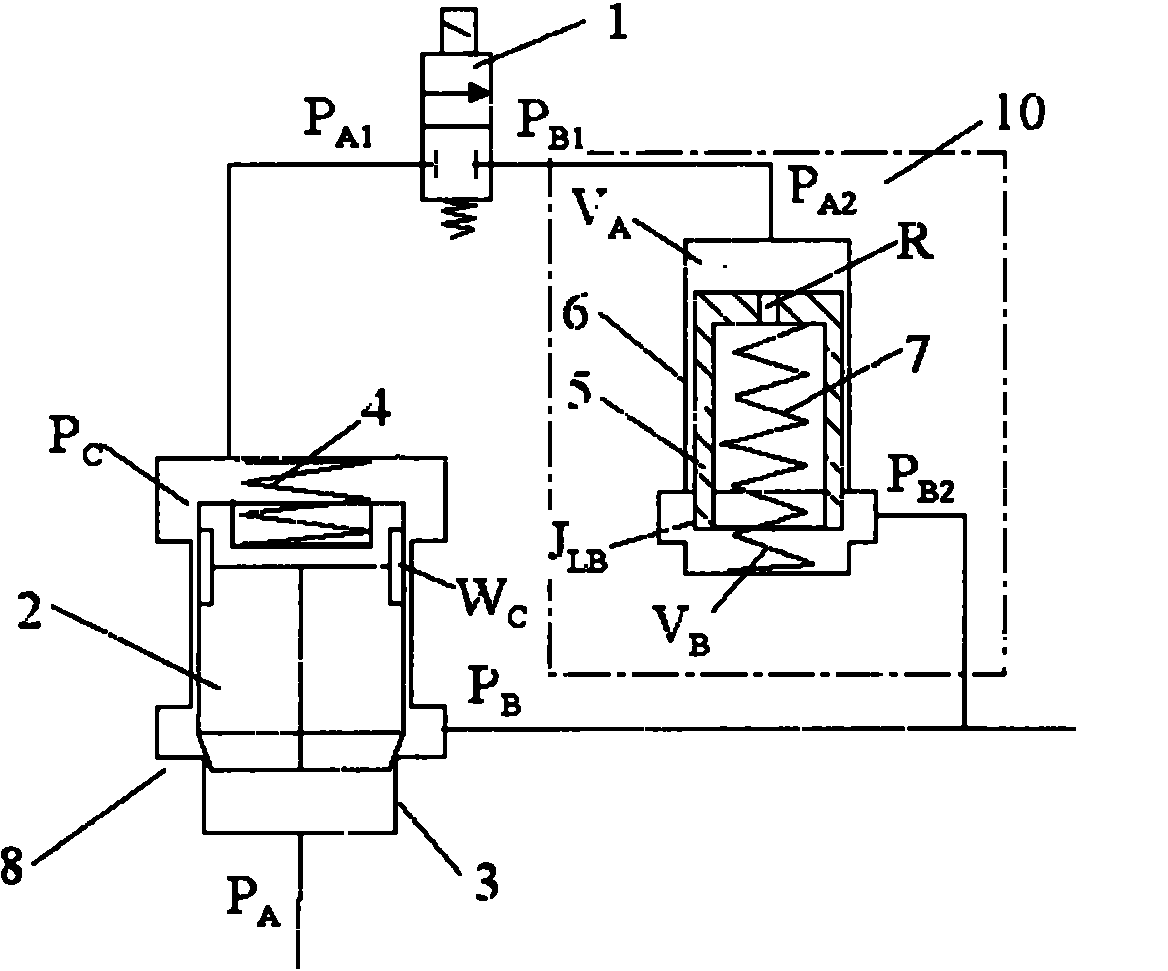

[0023] Such as image 3 As shown, the digitally controlled pilot-operated proportional flow valve in another embodiment of the present invention has the same structure as that in Embodiment 1, and the connection between the two-position two-way high-speed switch valve 1 and the main valve 8 and the fixed value flow device 10 In different ways, the main valve control chamber P C With two-position two-way high-speed switch valve 1 oil inlet P A1 Connection, oil inlet P of fixed value flowmeter A2 With two-position two-way high-speed switch valve 1 oil outlet P B1 Connection, fixed value flow meter outlet P B2 and main valve oil outlet P B connect.

Embodiment 3

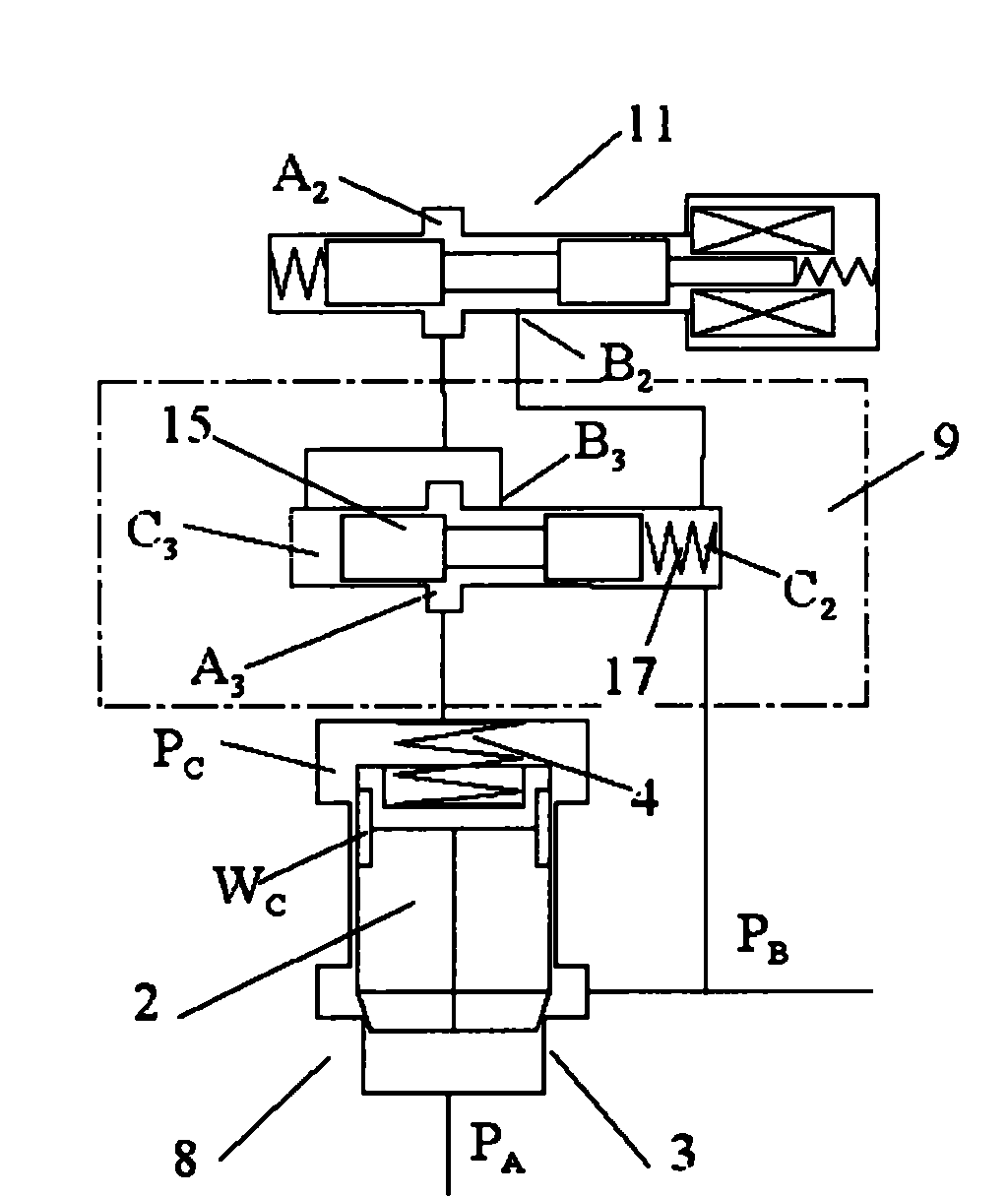

[0025] Such as Figure 4 As shown, the digitally controlled pilot proportional flow valve in another embodiment of the present invention is used in combination with two digitally controlled pilot proportional flow valves. It includes two two-position two-way high-speed switching valves 1 and 1', composed of the second main valve core 12, two second main valve sleeves 13 and 13', two second main valve springs 14 and 14', the total Oil inlet P, first oil outlet A, second oil outlet B, oil return tank port T, main valve first control chamber P C1 , The second control chamber P of the main valve C2 , the first flow feedback throttle slot W C1 , the second flow feedback throttling groove W C2 Composed of the second main valve 18 and two fixed value flowmeters 10 and 10'; two second main valve sleeves 13 and 13' are coaxially arranged at both ends of the second main valve core 12, and the first main valve spring 14 Set in the first control chamber P of the main valve C1 , the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com