Direct blowing type double-inlet and double-outlet steel ball grinding energy conservation optimization system and method thereof

A dual-in, dual-out, optimization method technology, applied in combustion methods, air supply regulation, indirect carbon dioxide emission reduction, etc., can solve problems such as increased output of primary fans, large throttling losses, and inability to fully open the capacity air adjustment damper. , to achieve the effect of reducing throttling loss and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

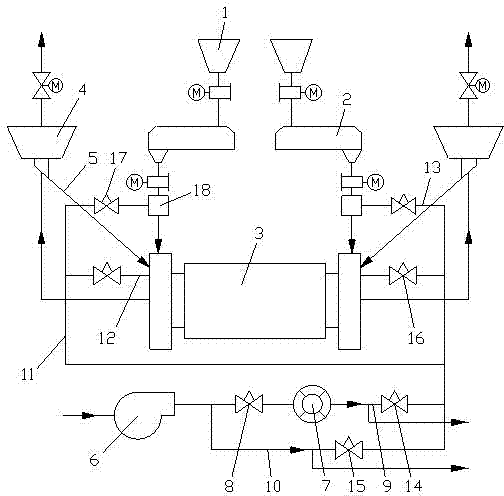

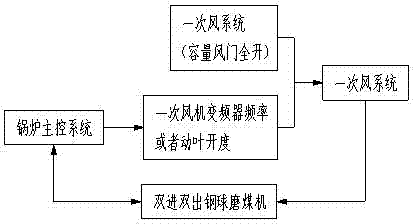

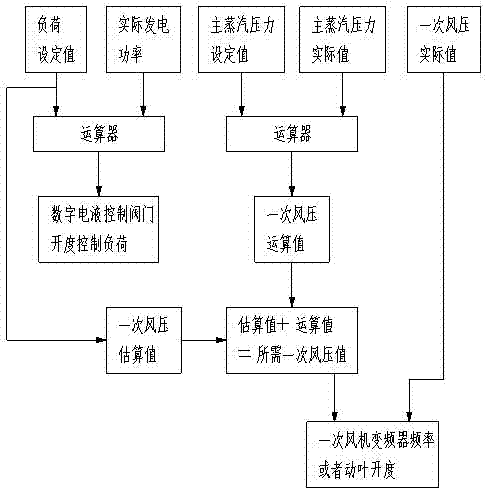

[0016] like Figure 1~3 As shown, a direct-blown double-inlet and double-outlet steel ball mill energy-saving optimization system includes a direct-blown double-inlet and double-outlet steel ball mill, a primary air system and a boiler main control system. The primary air system is mainly composed of moving blades The primary fan 6, the air preheater 7, the damper, the air duct, etc., the primary fan 6 outputs the primary air with relatively high pressure, and the primary air passes through the heat exchange of the air preheater 7 and becomes hot primary air. , the other path of the primary air that does not pass through the air preheater 7 is the cold primary air, and the inlet and outlet of the air preheater 7 are generally equipped with dampers, and the hot primary air and the cold primary air are respectively heated once The primary air duct 9 and the cold primary air duct 10 converge to the primary air duct 11, and the primary air duct 10 is divided into the mill air duct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com