Frequency-conversion pump controlled steering hydraulic system for loader

A technology for steering hydraulics and loaders, which is applied to fluid pressure actuating system components, mechanical equipment, accumulator devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

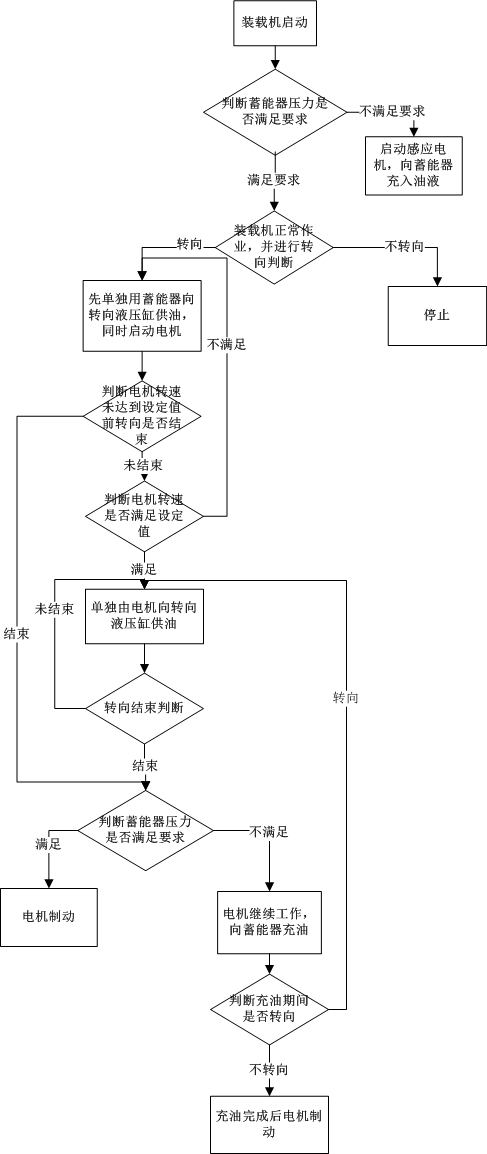

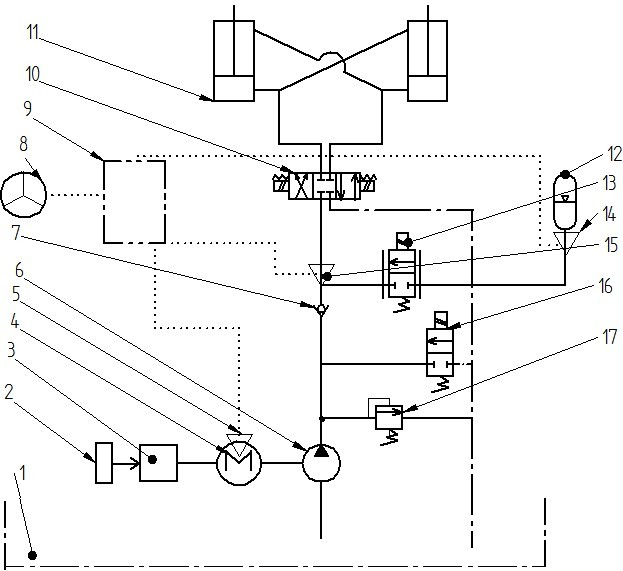

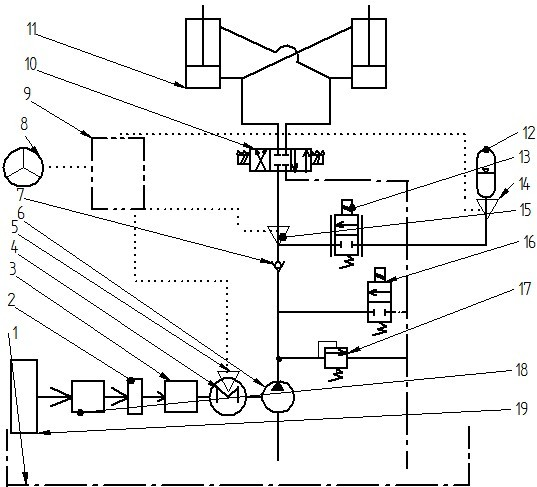

[0014] Specific implementation of technical solution 1 of the present invention: when the loader is started, the pressure sensor (14) transmits the pressure signal of the accumulator (12) to the controller (9), and the controller (9) determines that the accumulator ( 12) Whether the pressure meets the requirements. When the pressure in the accumulator (12) is low, the controller (9) controls the AC motor (4) to start, and controls the proportional valve (13) to open, and the three-position four-way reversing valve (10) and the on-off valve (16) are closed, at this time, the quantitative pump (6) is driven by the AC motor (4) to fill the accumulator (12) with high-pressure oil; when the pressure of the accumulator (12) is higher When it is high, the loader can start normal operation. The highest pressure in the accumulator (12) is the overflow pressure of the overflow valve (17), and the lowest pressure should be greater than the average pressure of the steering hydraulic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com