Elevated operation vehicle and platform leveling hydraulic system thereof

A hydraulic system and platform technology, which is applied in the field of lifting operation vehicle and its platform leveling hydraulic system, can solve the problems of leveling jitter, leveling instability, lag in leveling cylinder movement, and inability to guarantee stable flow, etc. The leveling process is stable and reliable, the response speed is fast, and the reliability is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

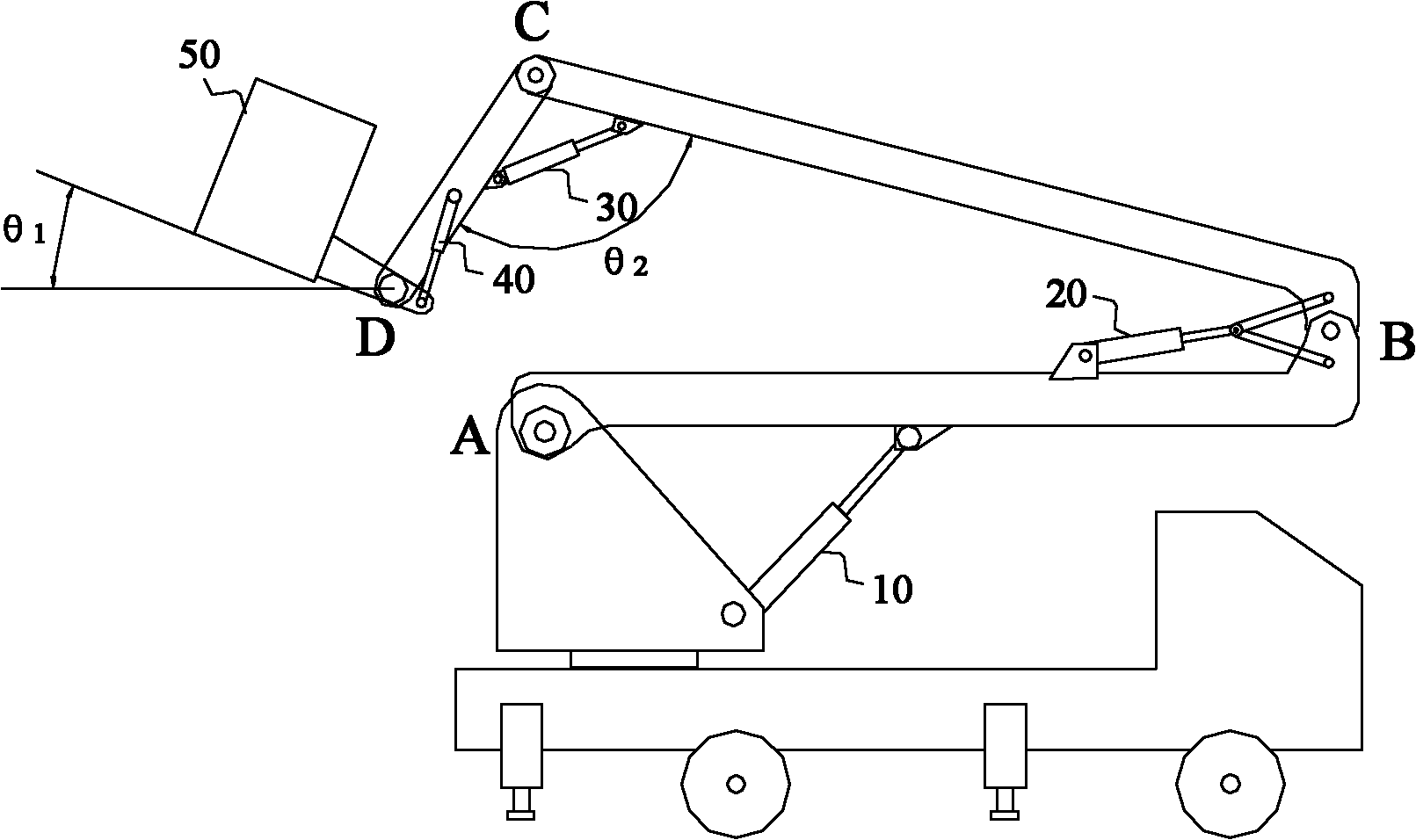

[0033] The core of the present invention is to provide a platform leveling hydraulic system, so that when the vehicle performs boom luffing operations, the system pressure oil first meets the flow requirements of the leveling cylinder, which can effectively avoid the phenomenon of platform leveling leading or lagging Appears to ensure a smooth and reliable leveling process. The specific implementation will be described in detail below with reference to the drawings in the specification.

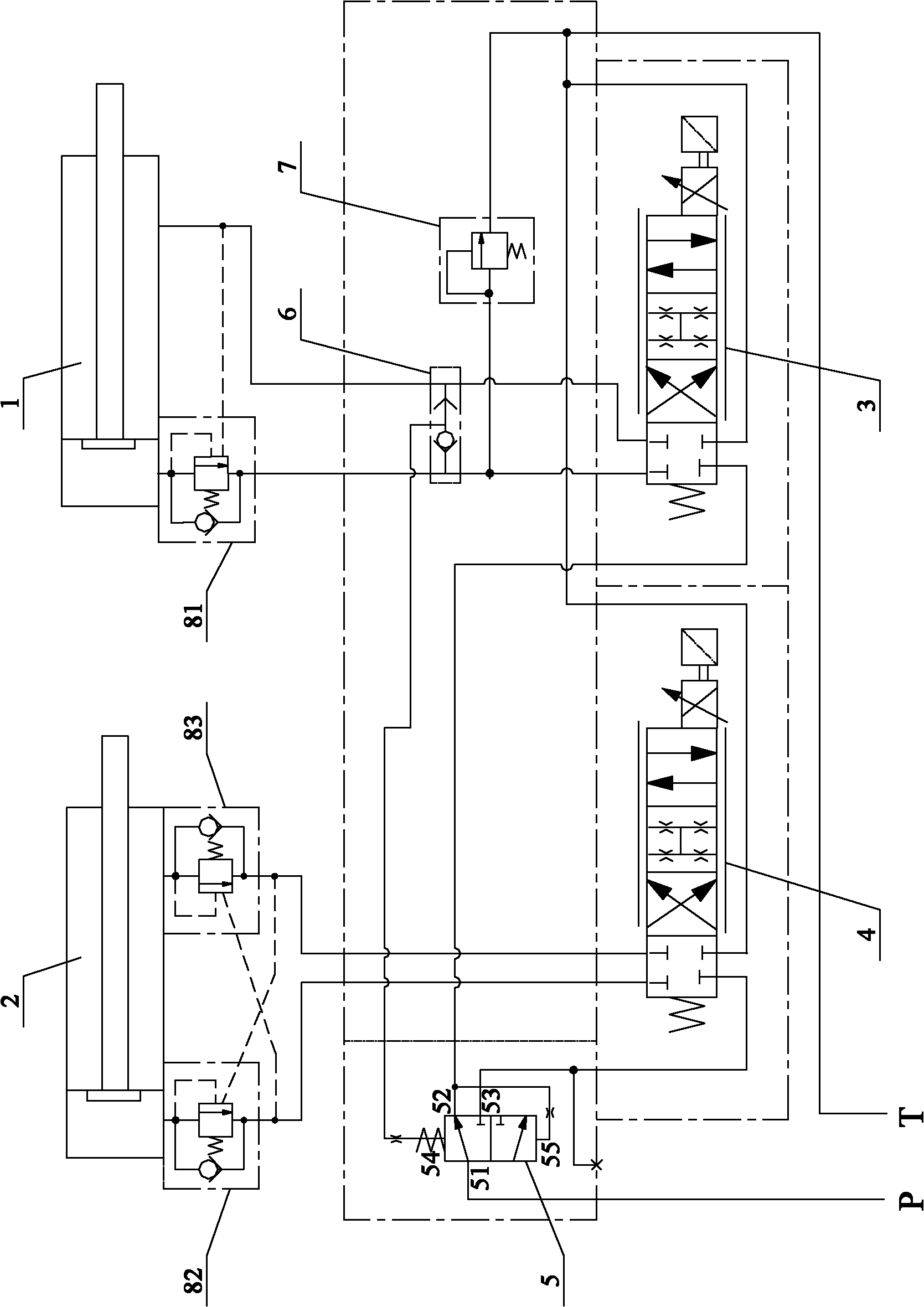

[0034] See image 3 , The figure is the working principle diagram of the first embodiment of the platform leveling hydraulic system.

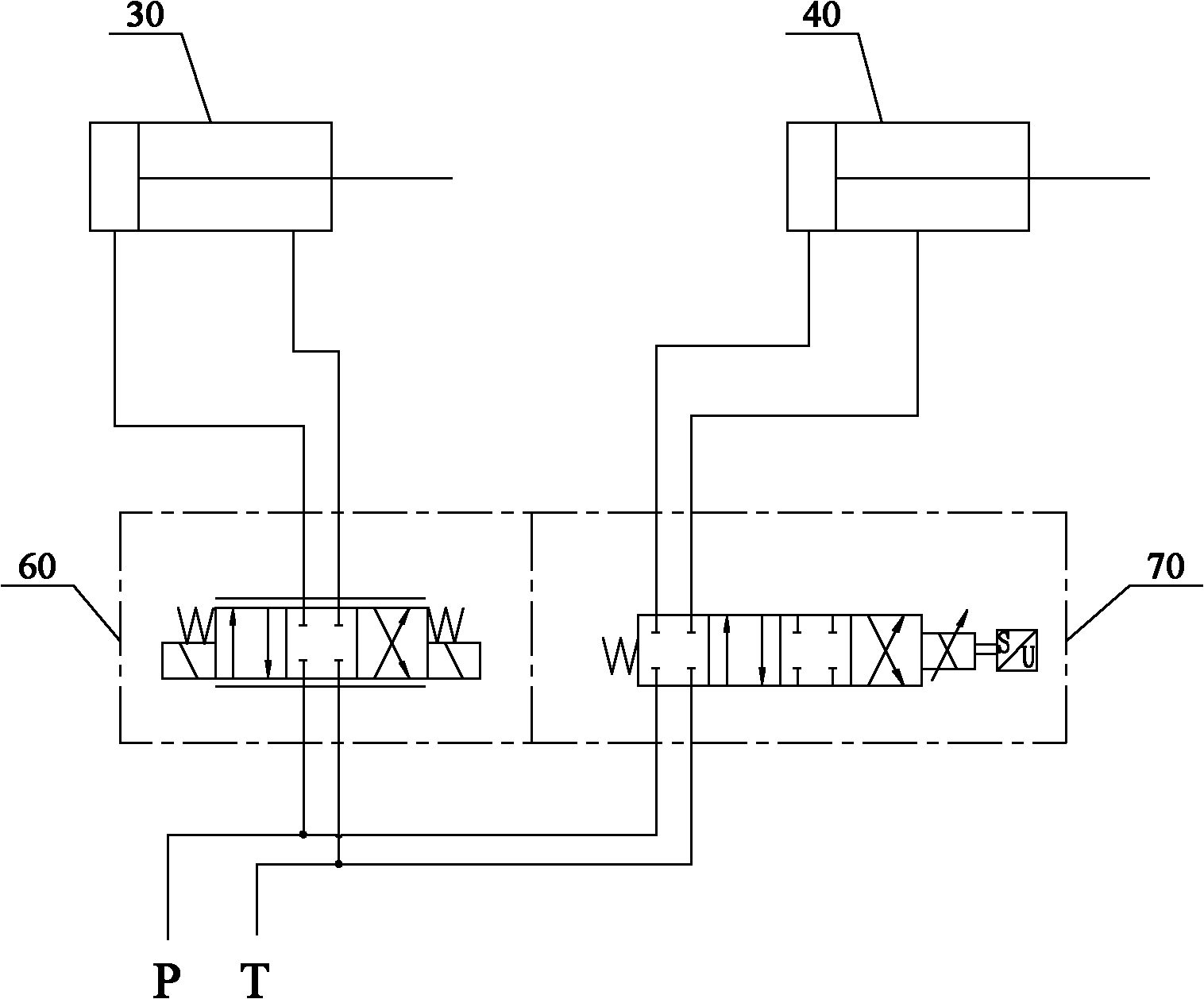

[0035] The platform leveling hydraulic system is used to control the platform articulated to the top section arm to maintain a horizontal state, specifically including: leveling cylinder 1, boom section luffing cylinder 2, two flow control valves (first flow control valve 3 and second Flow control valve 4) and priority valve 5. Similar to the prior art, the level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com