Hydro-pneumatic spring for amphibious vehicles and hydraulic regulating device for hydro-pneumatic spring for amphibious vehicle

A technology of oil-pneumatic springs and amphibious vehicles, applied in the field of hydraulic machinery, can solve the problems of adjusting the adjustment speed, many internal components, and high cost, and achieve the effects of reducing spring stiffness, improving damping characteristics, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

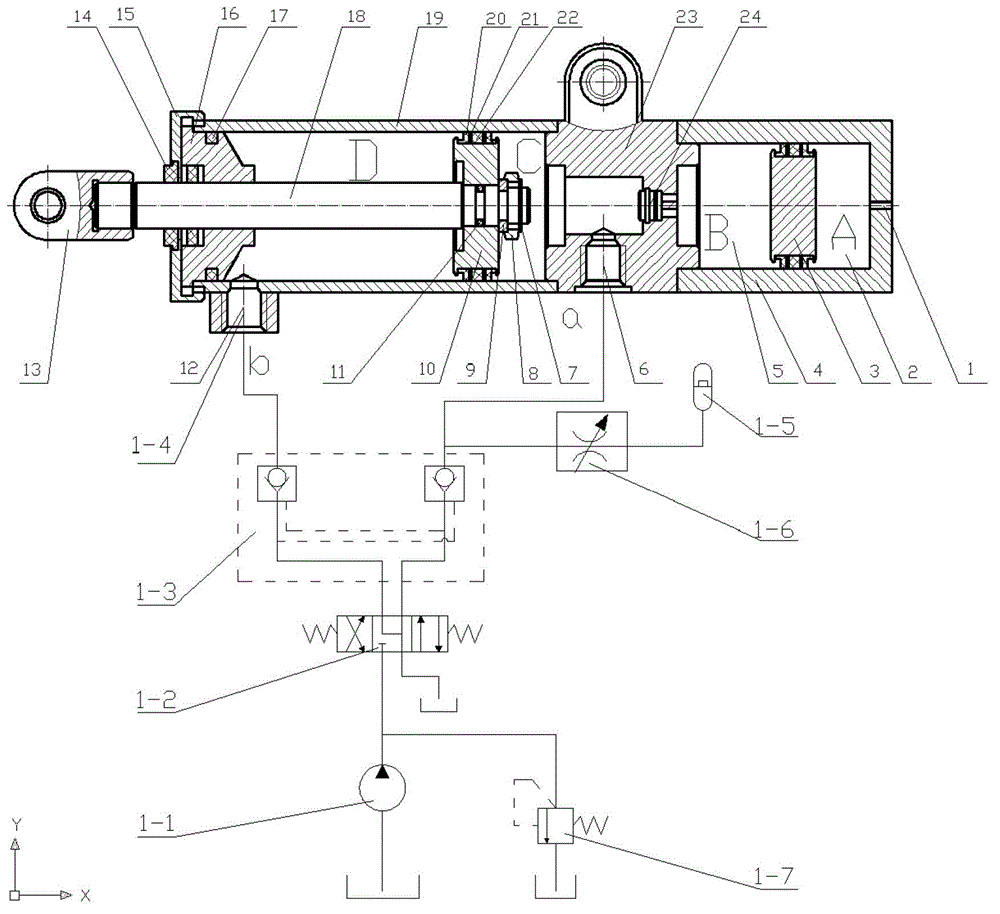

[0018] A kind of oil-pneumatic spring for amphibious vehicle and hydraulic adjustment device thereof of the present invention are described in detail below in conjunction with accompanying drawing:

[0019] Such as figure 1 As shown, a kind of oil-pneumatic spring used for amphibious vehicle comprises one end fixedly connected with one end of cylinder head 23, the other end is provided with cylinder barrel 19 of cylinder cover 15, piston 10 and piston rod 18, and one end of said piston rod 18 A piston 10 closely matched with the inner wall of the cylinder 19 is sleeved, and the piston 10 is fixed on the piston rod 18 through the spring retaining ring 7 , the collar 8 and the snap ring 9 . O-shaped sealing ring 11 is installed on the piston rod 18 to ensure the tightness of piston rod 18 and piston 10 . The piston 10 is in contact with the cylinder 19 through the support ring 22, and the sealing of the piston 10 and the cylinder 19 is guaranteed through the Y sealing ring 20; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com