Load-sensitive hydraulic system and power matching control method, device and system

A load-sensitive, hydraulic system technology that is applied to fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve problems such as poor stability, poor dynamic response, and throttle valve leakage, and improve control consistency , Improve the effect of handling and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

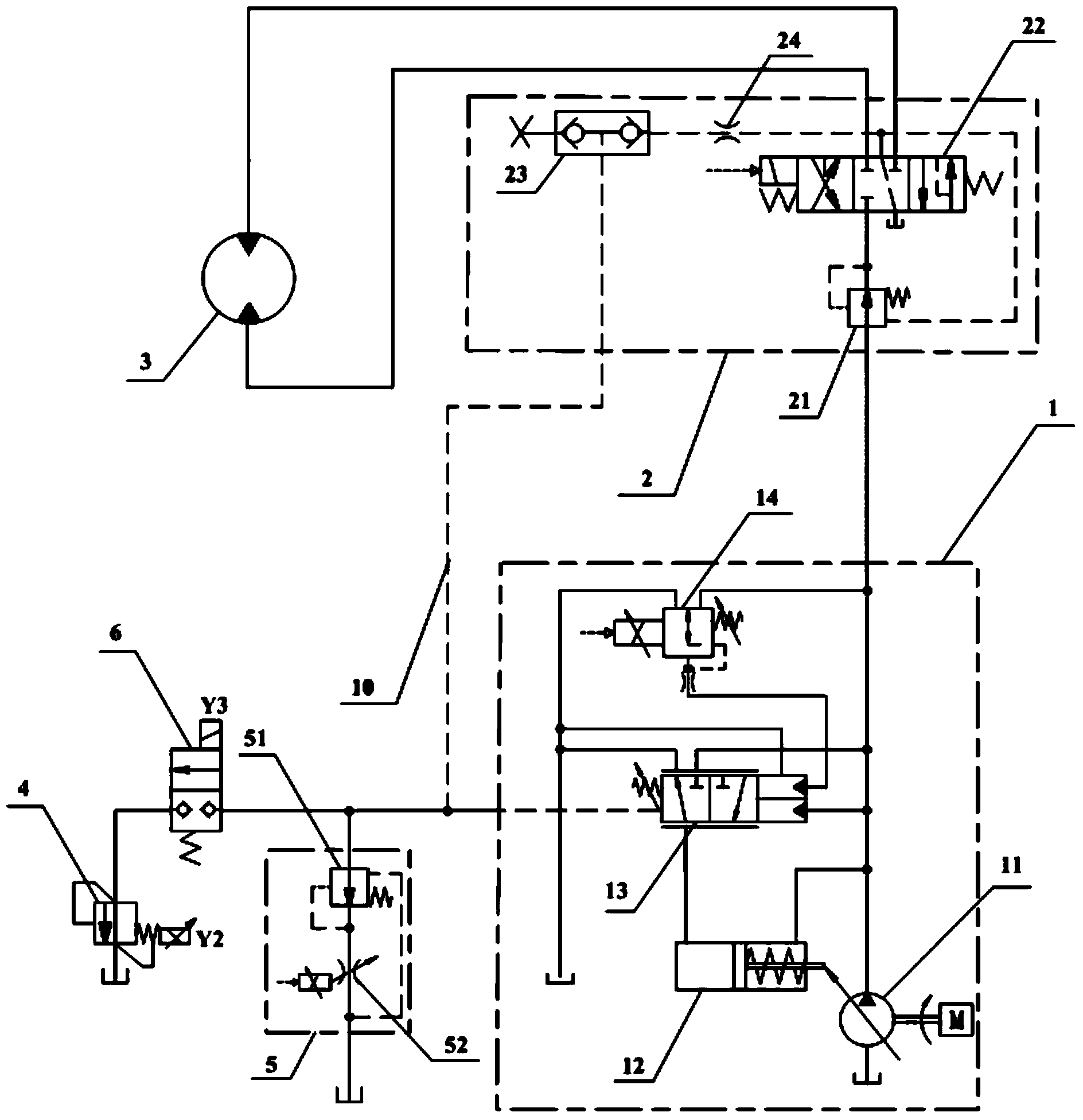

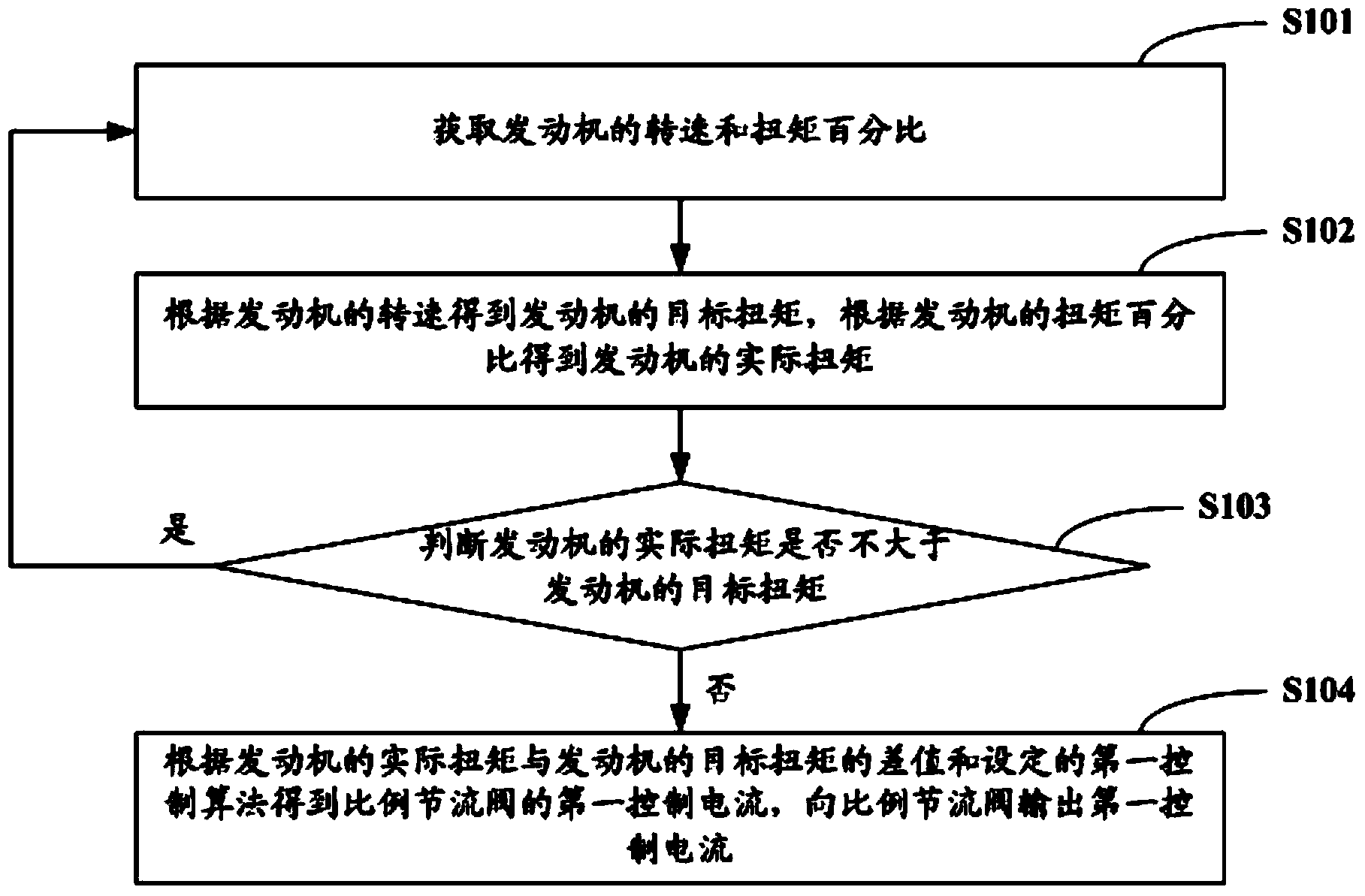

[0045]In order to improve the control consistency, dynamic response and stability of the load-sensing hydraulic system, as well as the control performance of power matching, the embodiment of the present invention provides a load-sensing hydraulic system, a power matching control method, device, system and a construction machinery. In the load-sensing hydraulic system provided, the load-sensing feedback oil circuit is connected with the inlet oil circuit of the relief valve, and a switching valve is arranged on the inlet oil circuit of the relief valve, and the load-sensing feedback oil circuit is also connected with the inlet oil circuit of the flow control valve group. The flow control valve group includes a proportional throttle valve and a first pressure compensating valve arranged on the inlet oil circuit of the proportional throttle valve. When it is necessary to adjust the pressure of the hydraulic system, open the on-off valve so that the oil inlet of the relief valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com