Non-oil-immersed air gap type hydraulic motor vane pump

A hydraulic motor and vane pump technology, which is applied to rotary piston/oscillating piston pump components, pump elements, mechanical equipment, etc., can solve the problems of reducing the total efficiency of hydraulic motor pumps, complex hydraulic power units, and increased additional heat generation , to achieve the effect of light weight, compact structure and sufficient oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

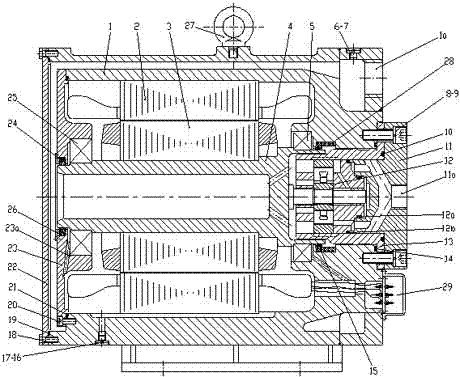

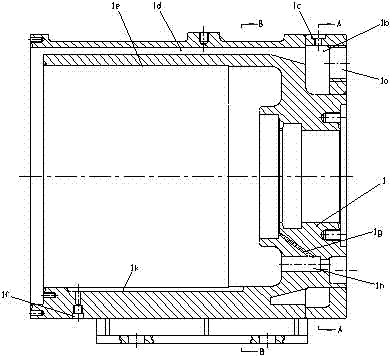

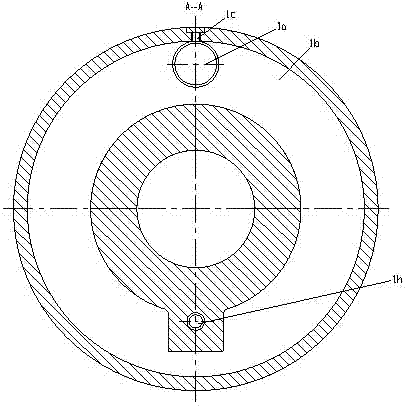

[0013] Such as Figure 1 to Figure 5 As shown, an air-gap non-oil-immersed electro-hydraulic power unit mainly includes a housing 1, a motor stator 2, a motor rotor 3, a main shaft 4, an oil outlet gland 11, a vane pump core 12, and a pump core seat 13 , the outer cover 22, the inner end cover 23, the suspension ring 27, the junction box 29, the motor rotor 3 and the main shaft 4 are press-fitted into one body, and are supported on the housing 1 and the inner end cover 23 through the first bearing 5 and the second bearing 25 Above, the vane pump core 12 is connected to the main shaft 4 through the spline 4c, the vane pump core 12 is installed in the pump core seat 13, and passes through the oil outlet gland 11, the second sealing ring 10, the fifth sealing ring 14, The first screw 8 and the first washer 9 are fixed on the casing 1, the motor stator 2 is press-fitted on the inner hole 1e of the casing 1, and the inner end cover 23 and the ninth sealing ring 21 are fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com