Lubricating and cooling jet nozzle for multi-station automatic cold header

A lubricating cooling and jet nozzle technology, applied in heating/cooling equipment, injection devices, manufacturing tools, etc., can solve the problems of polluting the factory environment, harmful to human body, etc., and achieve the effects of strong permeability, sufficient cooling, and reduction of oil mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

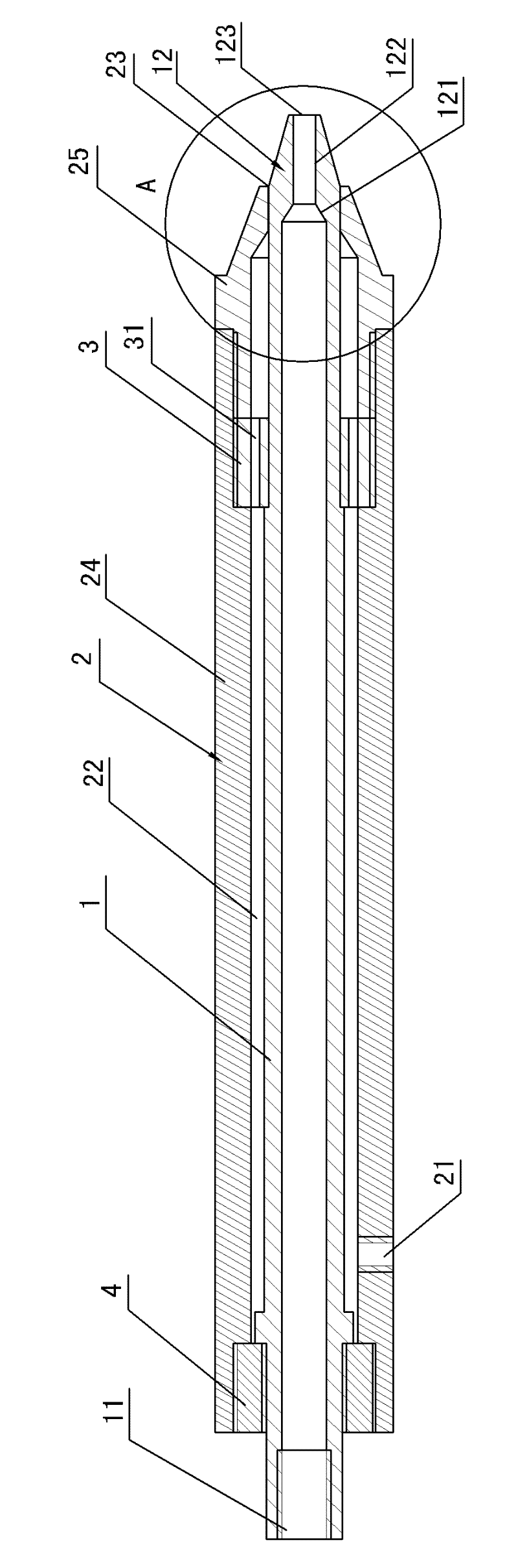

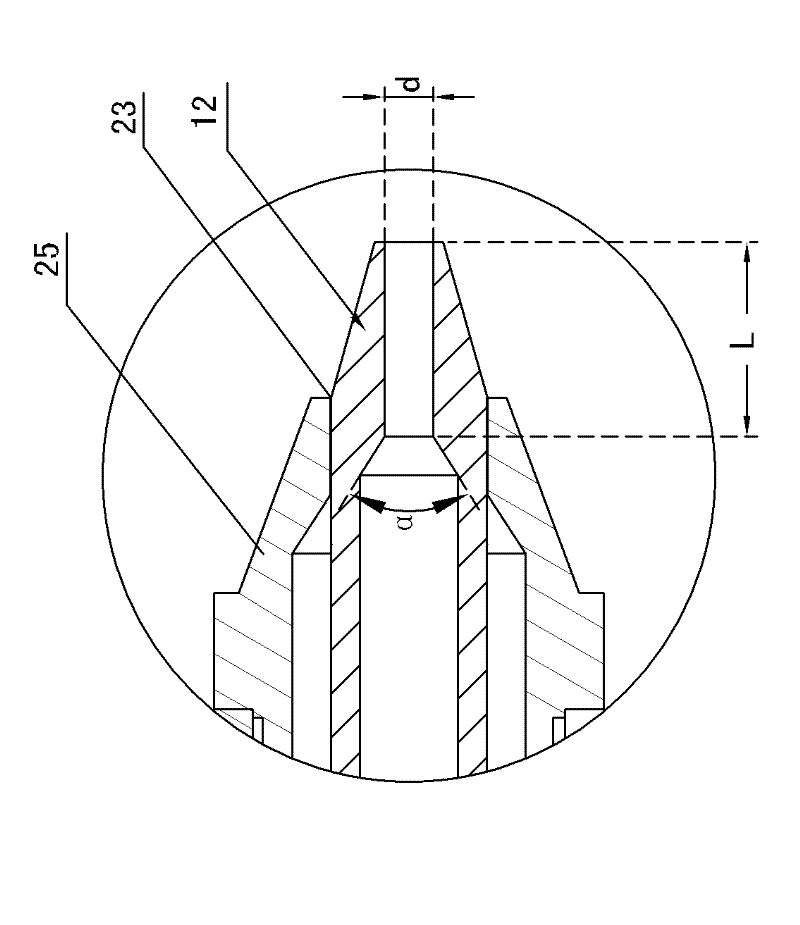

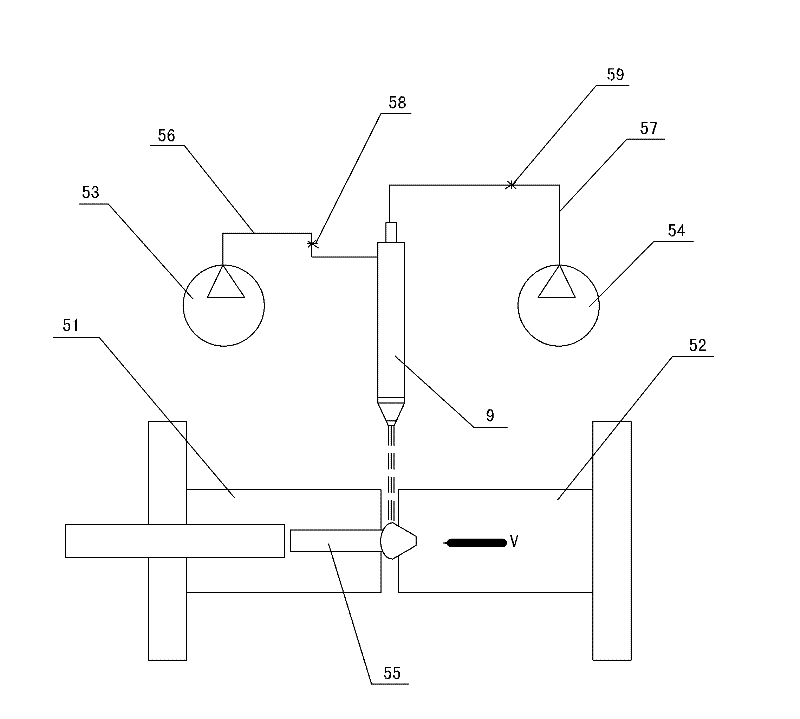

[0017] The present invention proposes a lubricating and cooling jet nozzle for a multi-station automatic cold heading machine, such as figure 1 and figure 2 As shown, it includes an oil injection pipe 1 and an air flow injection pipe 2 coaxially sleeved outside the oil injection pipe 1. The tail end of the air flow injection pipe 2 is sealed and connected with the tail of the oil injection pipe 1. The oil injection pipe The tail end of 1 is provided with an oil inlet 11, the front end of the oil injection pipe 1 is integrally provided with a constricted oil nozzle 12 for spraying continuous cylindrical oil jets, and the tail of the air flow injection pipe 2 is provided with an air inlet 21 The inner diameter of the air jet tube 2 is greater than the outer diameter of the oil jet tube 1, and the annular space between the inner peripheral wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com