Rotary valve and rotary control loop using same

A technology of rotary valve and control valve, which is applied to fluid pressure actuators, cranes, servo motors, etc., which can solve problems such as abnormal noise, reduce impact, and achieve stable start-stop operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

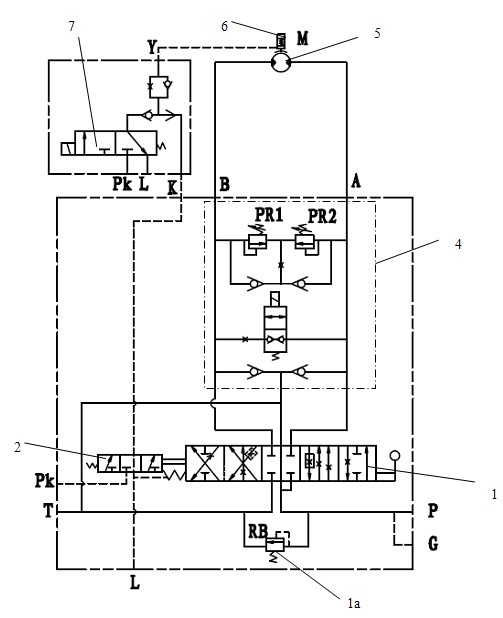

[0012] Below in conjunction with accompanying drawing, specific embodiment is described in detail as follows:

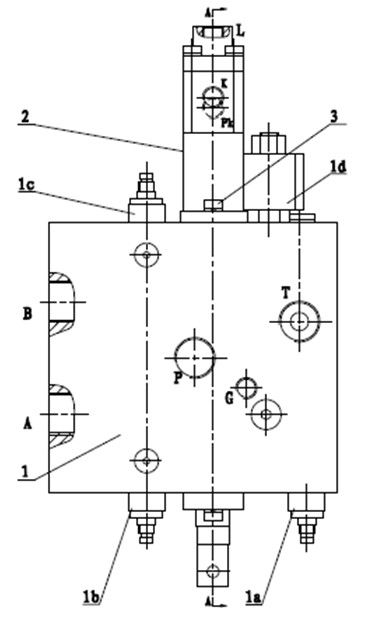

[0013] see figure 1 , The rotary valve of the present invention includes a main valve 1 and a control valve 2, and the two are connected by screws 3. The main valve 1 is equipped with a main relief valve 1a, which acts as overflow protection for the rotary valve. The main valve 1 is also equipped with overload valves 1b and 1c, which play an overload protection and buffer role for the rotary. In addition, it is also equipped with a solenoid valve 1d. After energizing, the slewing is in a free slip state.

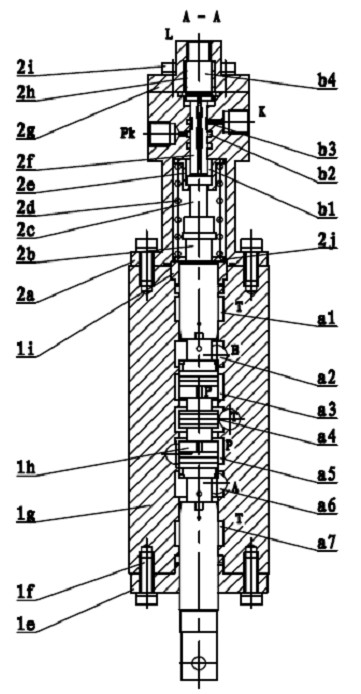

[0014] see figure 2 , the main valve 1 includes a valve body 1g and a main valve stem 1h located in the valve body 1g. The control valve 2 includes a control valve body 2a and a control valve rod 2f' located in the control valve body 2a, and the rotary valve also includes a connecting piece, which includes a connecting screw 2c and a positioning piece 2b. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com