Electronic control high-pressure common-rail fuel injection system for V-shaped diesel engine

A fuel injection system and high-pressure common rail technology, applied in fuel injection control, fuel injection device, electrical control, etc., can solve the problem that diesel engines cannot meet the needs of national development, and achieve high reliability, reduce emissions, and improve economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

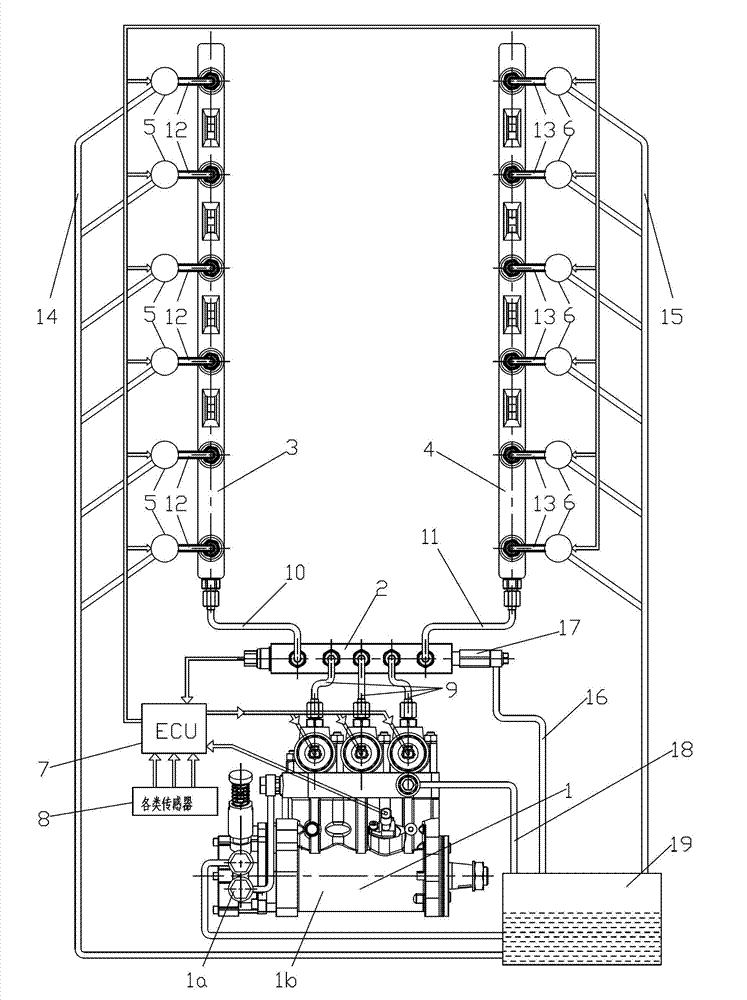

[0013] like figure 1 As shown, the electronically controlled high-pressure common rail fuel injection system in Embodiment 1 is used on a V-type 12-cylinder diesel engine. The electronically controlled high-pressure common rail fuel injection system is mainly composed of a common rail pump 1, a common rail pipe distributor 2, a first common rail pipe 3, a second common rail pipe 4, a first fuel injector 5, and a second fuel injector 6 , electronic control unit (ECU) 7, various sensors 8, high pressure oil pipe 9, first high pressure main oil pipe 10, second high pressure main oil pipe 11, second high pressure branch oil pipe 13, first oil return pipe 14, second oil return pipe 15 , the third oil return pipe 16, the pressure limiting valve part 17, the fourth oil return pipe 18 and the oil tank 19 and other components.

[0014] like figure 1 As shown, the oil inlet of the common rail pump 1 is connected to the oil tank 19, and the oil outlet of the common rail pump 1 is conne...

Embodiment 2

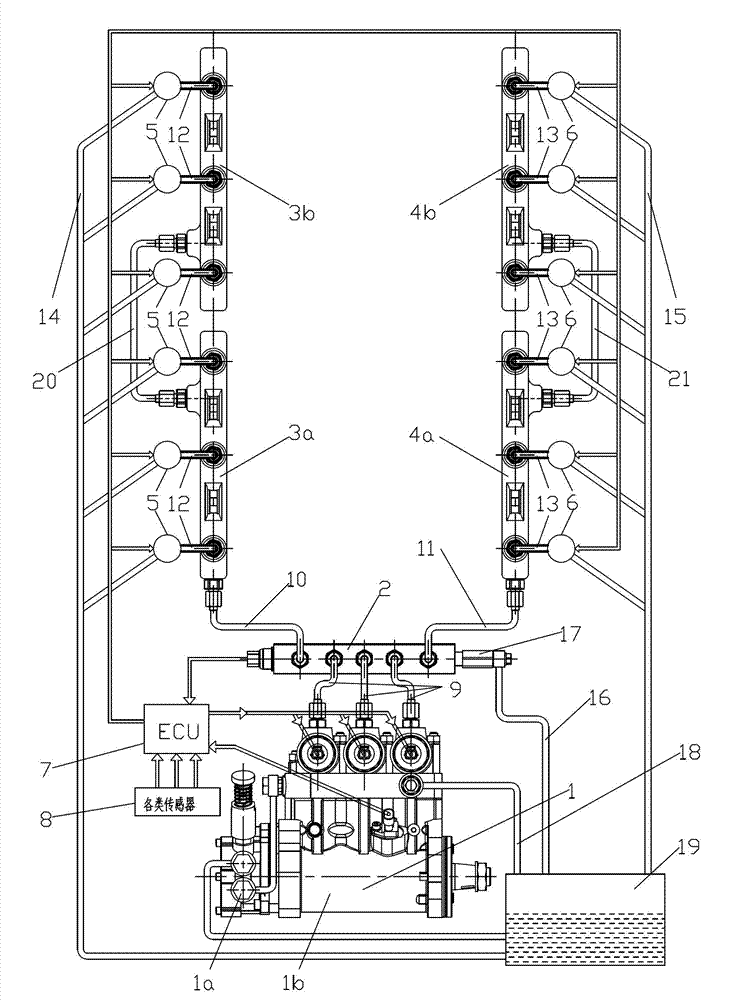

[0019] like figure 2 As shown, the electronically controlled high-pressure common rail fuel injection system in Embodiment 2 is also used in the V-type 12-cylinder diesel engine. The only difference between it and Embodiment 1 is that the first common rail pipe 3 is mainly composed of the first front common rail pipe 3a, the first rear common rail pipe 3b and the first high-pressure connecting oil pipe 20, and the first front common rail pipe 3a passes through The first high-pressure main oil pipe 10 is connected to the common rail pipe distributor 2, and the first rear common rail pipe 3b is connected to the first front common rail pipe 3a through the first high-pressure connecting oil pipe 20; the second common rail pipe 4 is mainly composed of the second front common rail pipe 3b. The rail pipe 4a, the second rear common rail pipe 5b and the second high-pressure connecting oil pipe 21 are composed, the second front common rail pipe 4a is connected with the common rail pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com