Self-cleaning air filter and self-cleaning step thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

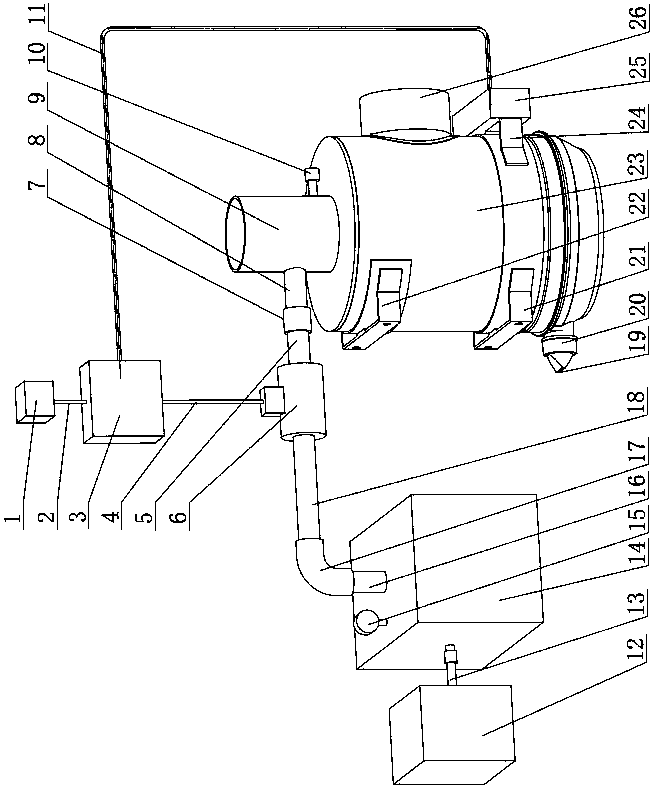

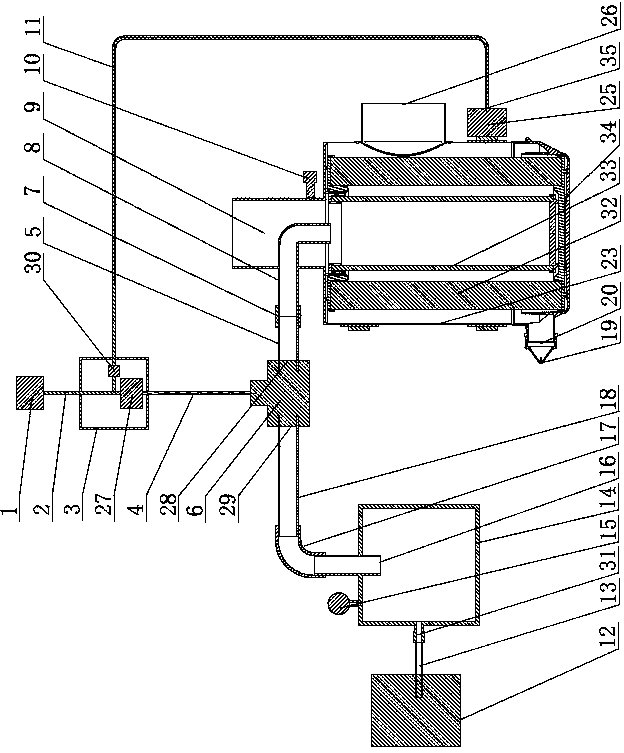

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0033] like figure 1 , figure 2 As shown, the air filter of the present invention has a circular cylindrical structure, and a safety filter element 33 and a main filter element 32 are sequentially arranged in the air filter housing 23 from the inside to the outside, and an air inlet 26 is arranged on one side of the housing 23 Corresponding to the safety filter element 33, a cylindrical air outlet 9 is provided above the housing 23, and the diameter of the air outlet 9 is less than or equal to the inner diameter of the safety filter element 33. The end cover 34 is set at the bottom of the air filter housing 23, the ash discharge port 20 is set on one side of the bottom of the housing 23, and the end of the ash discharge port 20 is provided with an ash discharge valve 19, a small amount of dust outside the safety filter element 33 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com