Preparation method of titanium alloy surface passivation film transmission observation sample

A technology of titanium alloy and passivation film is applied in the field of preparation of samples for transmission observation of passivation film on the surface of titanium alloy, which can solve the problems of high cost, complicated process and low success rate, and achieves low cost, simple process and high success rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the titanium alloy surface passivation film transmission observation sample of the present invention, the preparation process includes conventional double spray thinning treatment, cathode polarization, anode passivation and other three parts, the specific steps are as follows:

[0039] (1) Double spray thinning treatment

[0040] The thin area of the alloy transmission sample is prepared by the double-jet thinning method, and the preparation equipment is the "Denmark Struers company Tenupol-5 double-jet thinning instrument".

[0041] In the present invention, the alloy transmission sample is a disc-shaped conventional plane sample with a diameter of Φ3mm. Before double jet thinning, the sample is polished step by step with 800#-2000# SiC water abrasive paper to a thickness of 40μm-50μm. Use liquid nitrogen to keep the double jet temperature in the range of -20°C to -30°C, adjust the flow rate (the flow rate ranges from 80ml / min to 100ml / min)...

Embodiment 1

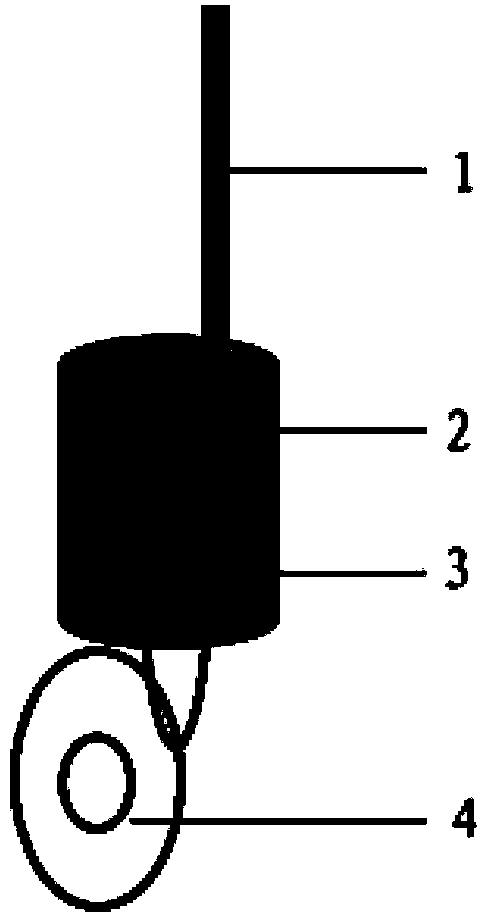

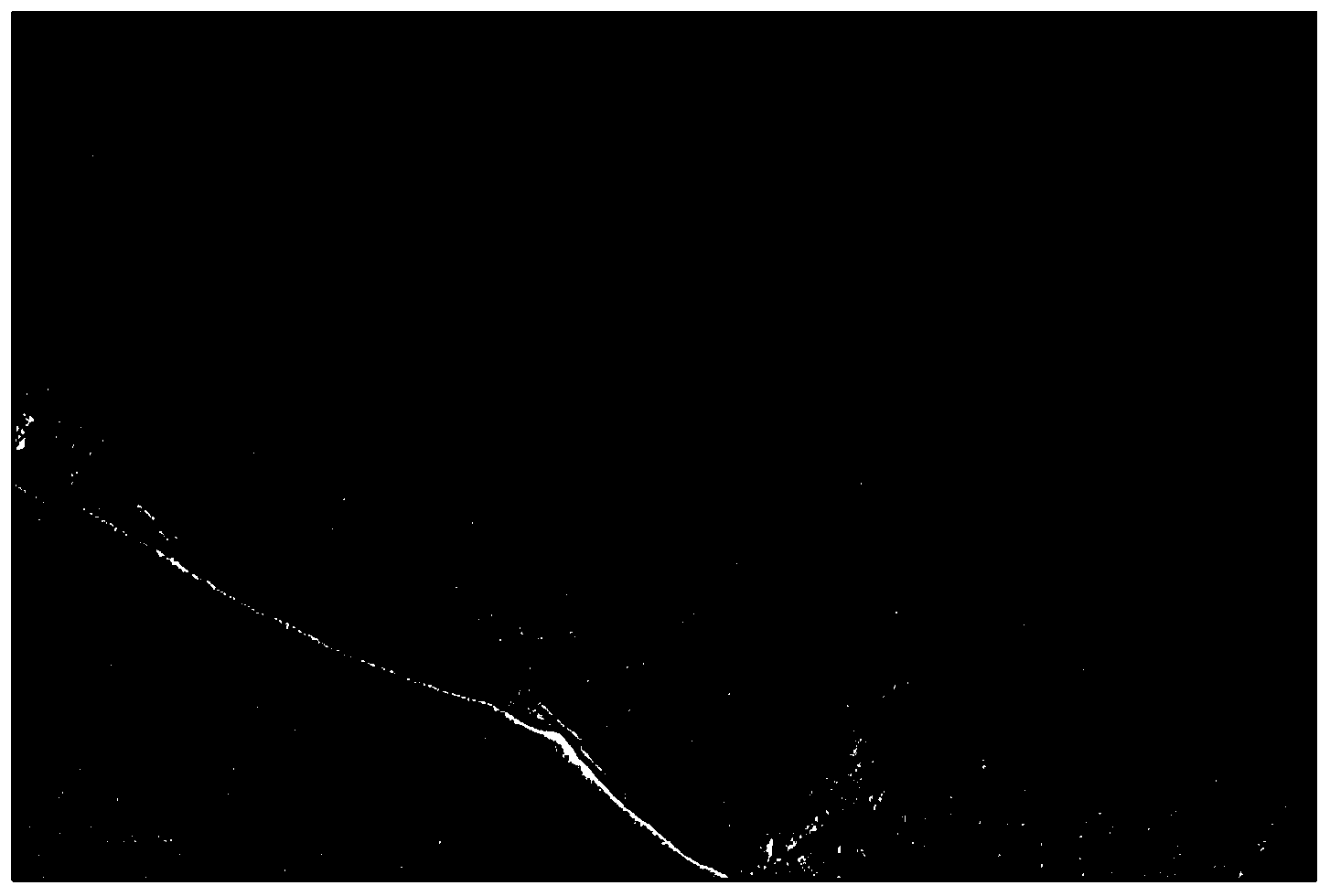

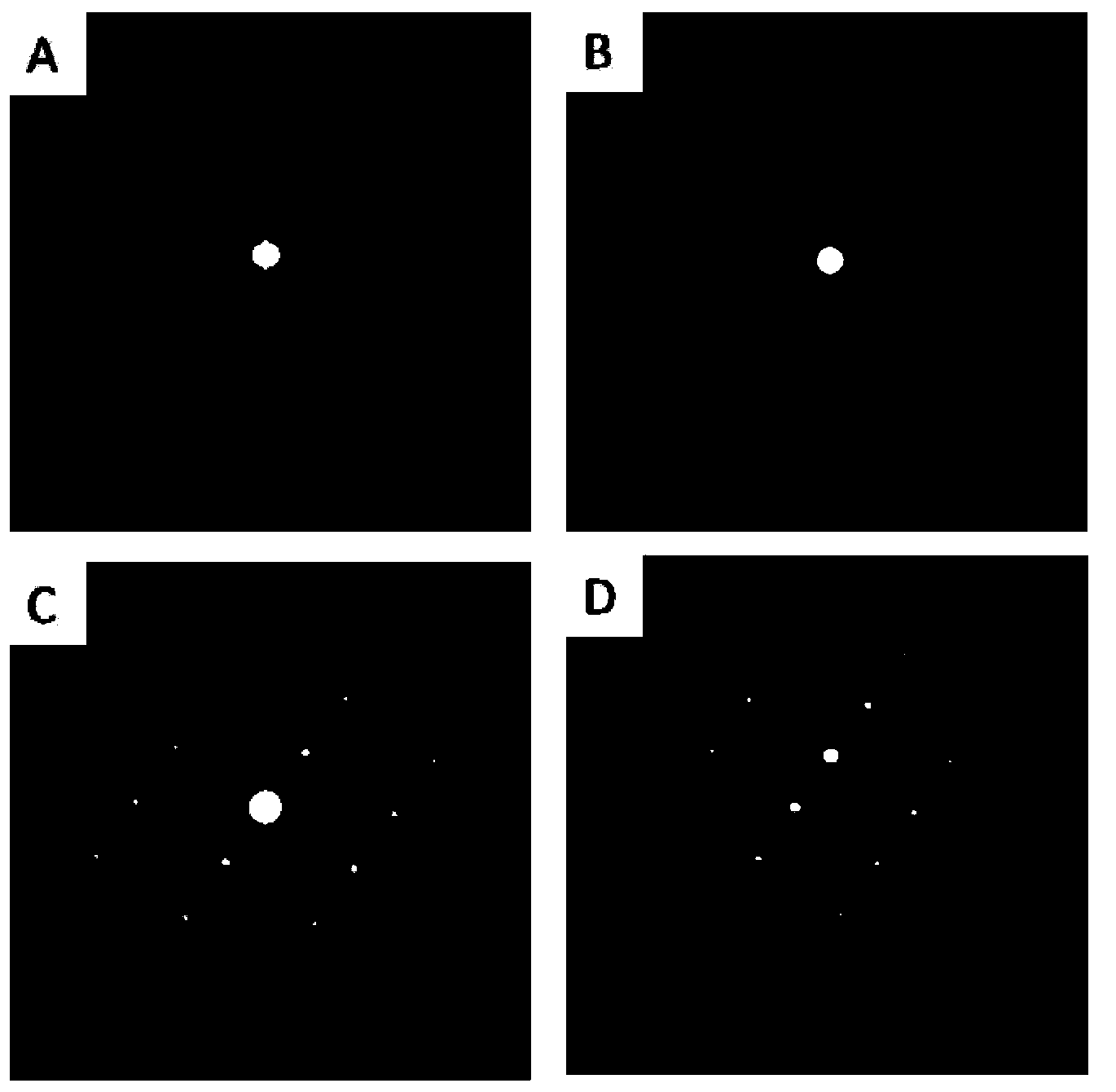

[0055] A pure titanium plane transmission sample with uniform distribution of thin areas was prepared by the "double jet thinning method". After washing and drying, the figure 1 Connect as shown. A three-electrode system was adopted, the electrode connected to the planar transmission sample was connected as the working electrode, and the cathodic polarization was performed under the constant potential mode of the electrochemical workstation. Let it stand for about 1 hour to stabilize the open circuit potential, then apply a voltage of -1V for 5 minutes to remove the surface oxide film; then apply a voltage of 1.0V for anode passivation for about 2 hours; the front end of the thin area is completely passivated Transmission samples such as figure 2 shown. In this embodiment, the electrolytic solution used for cathodic polarization and anode passivation uses NaCl as the electrolyte, and the concentration of the electrolytic solution is 0.5 wt%.

[0056] In this embodiment, th...

Embodiment 2

[0058] A flat transmission sample of Ti-6Al-4V alloy with uniform distribution of thin areas was prepared by "double-jet thinning method". After washing and drying, according to figure 1 Connect as shown. A three-electrode system was adopted, the electrode connected to the planar transmission sample was connected as the working electrode, and the cathodic polarization was performed under the constant potential mode of the electrochemical workstation. Stand for about 2 hours to stabilize the open circuit potential, then apply a voltage of -0.8V for 5 minutes to remove the surface oxide film; then apply a voltage of 0.5V for anode passivation for about 4 hours; the front end of the thin area is completely passivated transmission samples, such as Figure 4 shown. In this embodiment, the electrolytic solution used for cathodic polarization and anode passivation uses NaCl as the electrolyte, and the concentration of the electrolytic solution is 1 wt%.

[0059] In this embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com