Compound airflow generator, circulating fluidized bed tower-front two-phase premixing device and method

A circulating fluidized bed and composite air flow technology, applied in the field of flue gas purification, can solve the problem of unimproved mixing and uniform distribution of material particles and flue gas, uneven mixing and distribution of flue gas and material particles, and increase of material particles. concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

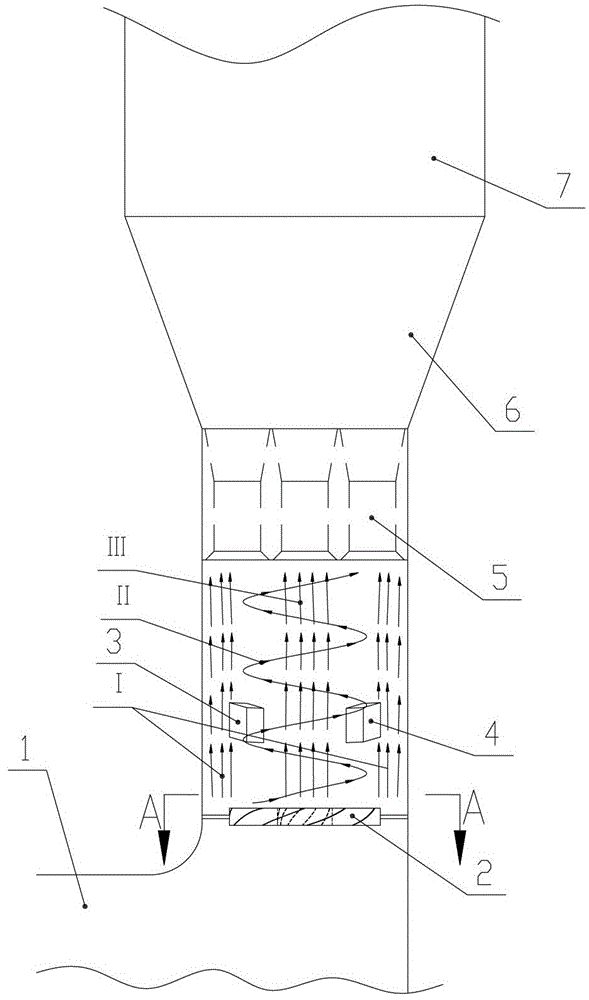

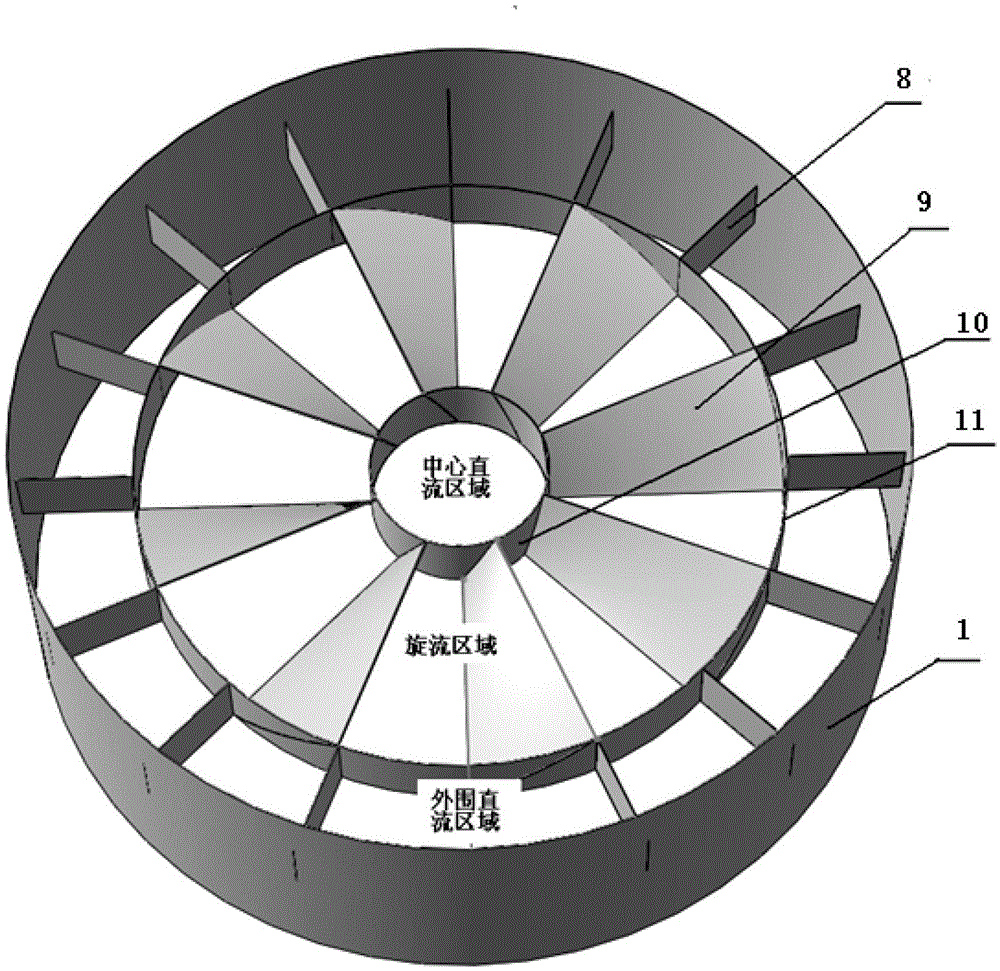

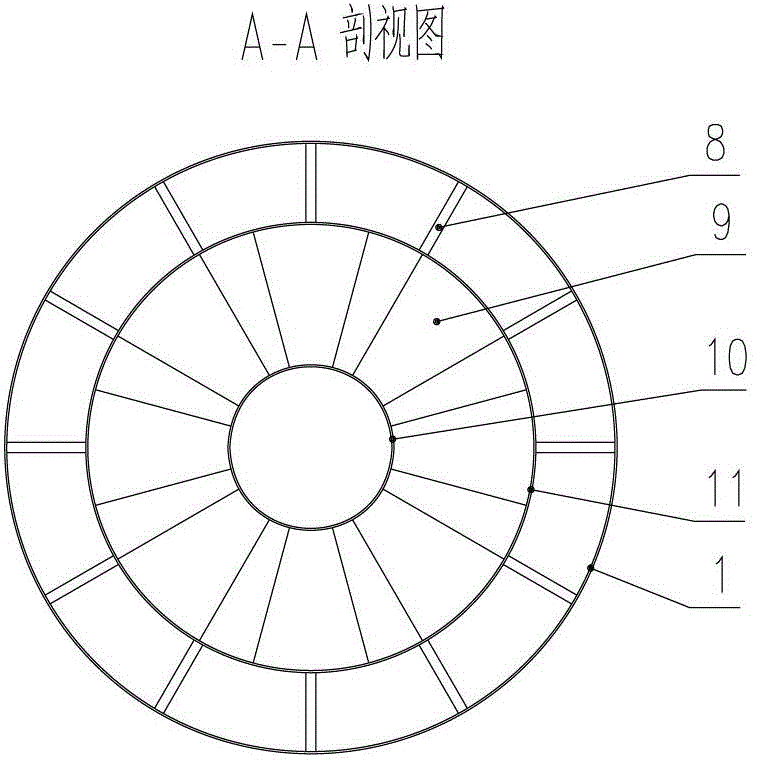

[0067] according to figure 1 As shown in the schematic diagram of the structure, the composite air flow generator is assembled. The cross-sectional area of the inner sleeve accounts for 12% of the cross-sectional area of the flue, and the cross-sectional area between the inner sleeve and the outer sleeve accounts for 58% of the cross-sectional area of the flue. The cross-sectional area between the outer sleeve and the inner wall of the flue accounts for 30% of the cross-sectional area of the flue; 15 swirl vanes are set between the inner sleeve and the outer sleeve, and each swirl guide vane is connected with the flue The included angle of the central axis is 45°; so that the flow rate of the direct air flow in the central area of the flow field is 15% of the total smoke flow; the flow rate of the direct air flow in the peripheral wall area is 35% of the total smoke flow; The flow rate is 50% of the total flue gas flow; the angle between the velocity direction of the...

Embodiment 2

[0073] Assemble the composite air flow generator according to the technical scheme of embodiment 1, the difference is that the cross-sectional area of the inner sleeve accounts for 5% of the cross-sectional area of the flue in this embodiment; the cross-sectional area between the inner sleeve and the outer sleeve The area accounts for 50% of the cross-sectional area of the flue; the cross-sectional area between the outer sleeve and the inner wall of the flue accounts for 45% of the cross-sectional area of the flue; 6 swirl blades are set between the inner sleeve and the outer sleeve , the angle between each swirl guide vane and the central axis of the flue is 30°; so that the flow rate of the direct current flow in the central area of the flow field is 7% of the total smoke flow; 50%; the swirling air flow between the two is 43% of the total flue gas flow; the angle between the speed direction of the swirling air flow and the direction of the flue gas flow is 30°;

...

Embodiment 3

[0078] Assemble the composite air flow generator according to the technical scheme of Example 1. The difference is that the cross-sectional area of the inner sleeve in this embodiment accounts for 10% of the cross-sectional area of the flue, and the cross-sectional area between the inner sleeve and the outer sleeve The area accounts for 51% of the cross-sectional area of the flue, and the cross-sectional area between the outer sleeve and the inner wall of the flue accounts for 39% of the cross-sectional area of the flue; 10 swirls are evenly arranged between the inner sleeve and the outer sleeve Blades, the angle between each swirl guide vane and the central axis of the flue is 40°; so that the direct current flow in the central area of the flow field is 12% of the total flue gas flow; the direct current flow in the peripheral wall area is the total flue gas flow 43% of the swirling airflow between the two is 45% of the total flue gas flow; the angle between the veloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com