Degradable antifouling thermoplastic micro-airbag polymer elastomer material and preparation thereof

A technology of elastomer materials and polymer materials, applied in the direction of coating, etc., can solve the problems of easy dirtying of materials, lack of effective control and consideration, etc., to achieve the effect of reducing conductivity and polarity, improving oil resistance, and increasing tactility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

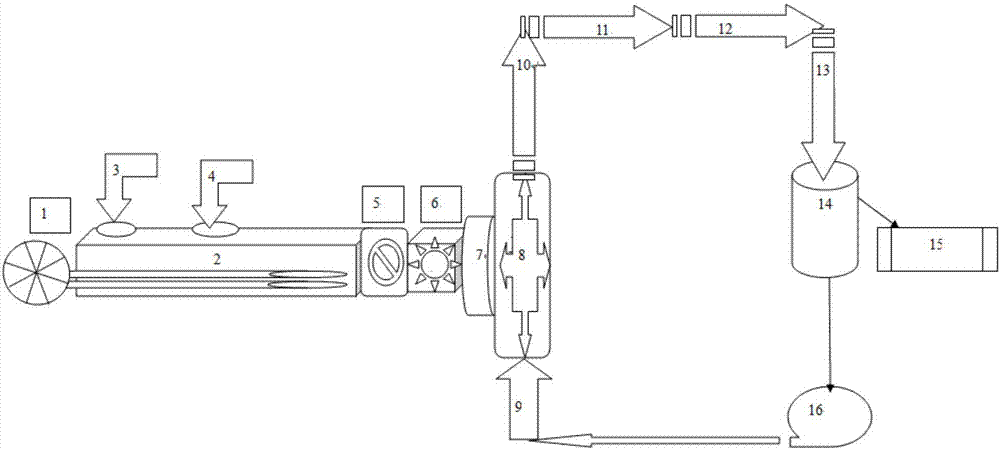

[0064] The preparation method of degradable antifouling thermoplastic micro-airbag polymer elastomer material may preferably comprise the following steps:

[0065] (1) Feed polymer raw materials, nucleating agents and environmentally friendly degradable organic perfluorinated materials from the feed port at the front end of the twin-screw extruder, and feed the foaming agent from the feed port in the middle of the twin-screw extruder, so that the raw materials are heated After the melting and mixing are sufficient, it enters the static mixer for further homogenization, and then is pressure-controlled and quantitatively transported by the melt pump;

[0066] (2) The hot melt pumped out by the melt pump enters the underwater pelletizing chamber through the die head to be pelletized, and is taken out by the process water for separation, and the obtained pellets are screened and dried to form the target product.

[0067] More preferably as the preferred technical solution above, t...

Embodiment 1

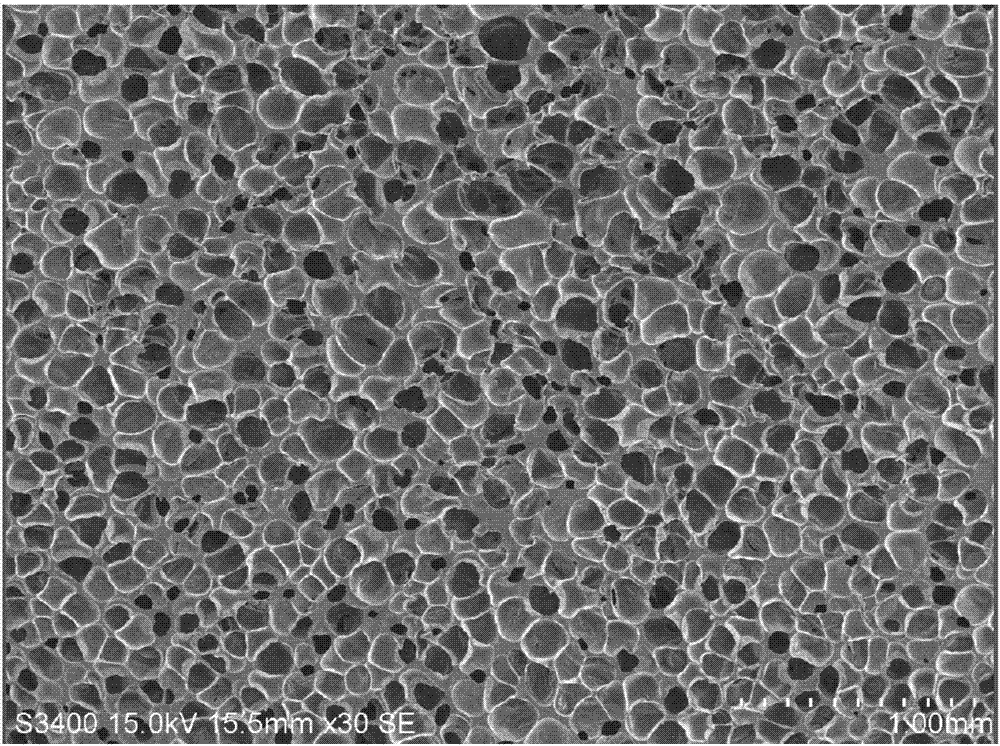

[0076] According to the above as figure 1 The technical process prepares the thermoplastic micro-airbag polymer elastomer material of the present invention according to the following raw material formula and process conditions:

[0077] Among them, molecular weight M w In 150K~300K (here K represents the unit thousand) polyether thermoplastic polyurethane, the addition ratio is 75% (weight percentage, the same below), the molecular weight M w For 50K-100K polyether thermoplastic polyurethane, the addition ratio is 20%, the addition amount of environmentally friendly and degradable organic perfluorinated materials is 2.5%, and the foaming agent is CO 2 , the addition amount is 2%, and the nucleating agent is calcium carbonate, and the addition amount is 0.5%. Twin-screw extruder length-to-diameter ratio L / D=40, screw heating temperature 160-220°C, static mixer temperature 140-180°C, melt pump inlet pressure 100-150bar, process water pressure about 12bar, just entering the und...

Embodiment 2

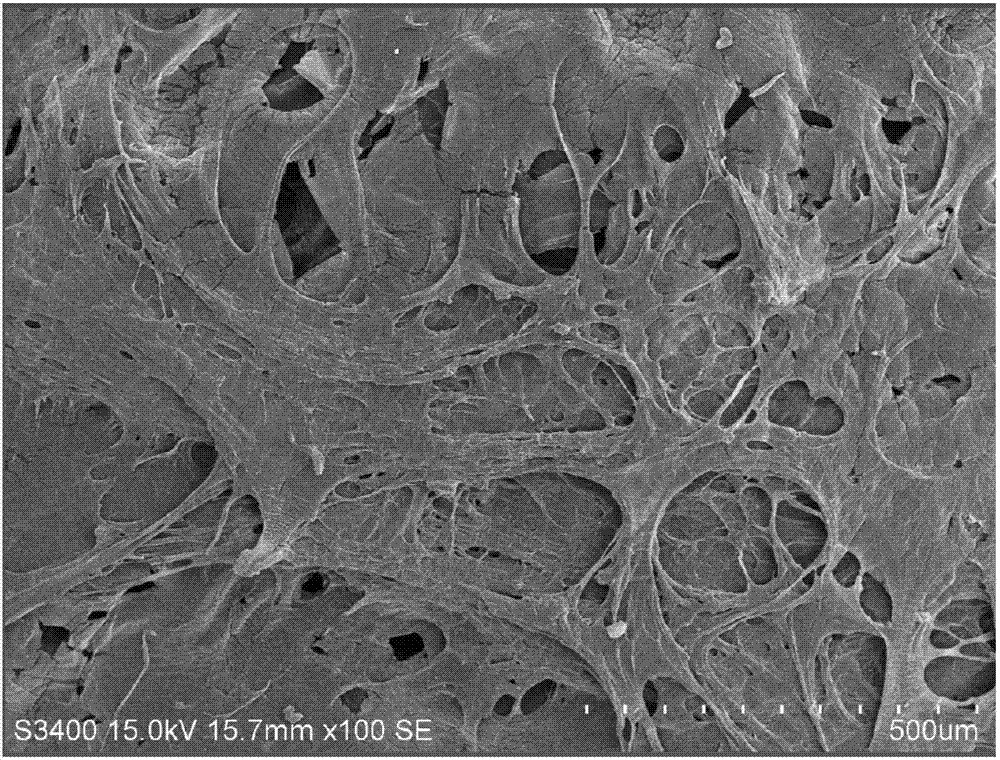

[0080] According to the above as figure 1 The technical process prepares the thermoplastic micro-airbag polymer elastomer material of the present invention according to the following raw material formula and process conditions:

[0081] Among them, molecular weight M w In 300K~500K polyether thermoplastic polyurethane, the addition ratio is 70% (weight percentage, the same below), and the molecular weight is M w For 150K-250K polyether thermoplastic polyurethane, the addition ratio is 18.1%, the addition amount of environmentally friendly and degradable organic perfluorinated materials is 10%, and the foaming agent is N 2 , the addition amount is 1.4%, and the nucleating agent is carbon black, and the addition amount is 0.5%. Twin-screw extruder length-to-diameter ratio L / D=56, screw heating temperature 160-220°C, static mixer temperature 140-180°C, melt pump inlet pressure 100-150bar, process water pressure about 6bar, just entering the underwater cutting The temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com