A kind of preparation method of hydrogenated nitrile rubber

A technology for hydrogenating nitrile-butadiene rubber and nitrile-butadiene rubber, which is applied to the preparation of hydrogenated nitrile-butadiene rubber, and the field of preparing hydrogenated nitrile-butadiene rubber from the catalytic hydrogenation of nitrile-butadiene rubber, can solve the difficulty of catalyst separation, harsh reaction conditions, low catalytic activity, etc. problem, to achieve the effect of high recycling efficiency, low cost and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Present embodiment provides a kind of preparation method of hydrogenated nitrile butadiene rubber, it may further comprise the steps:

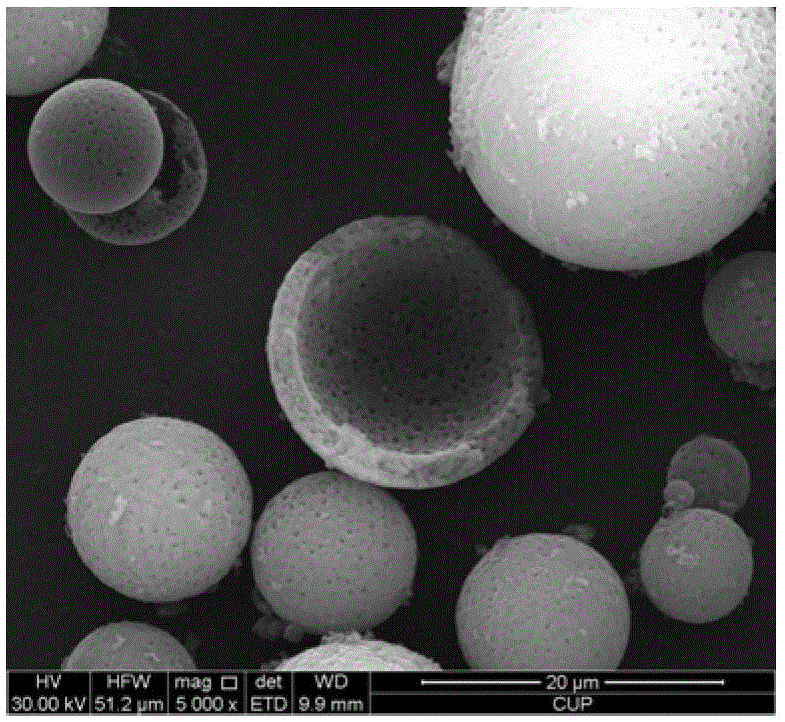

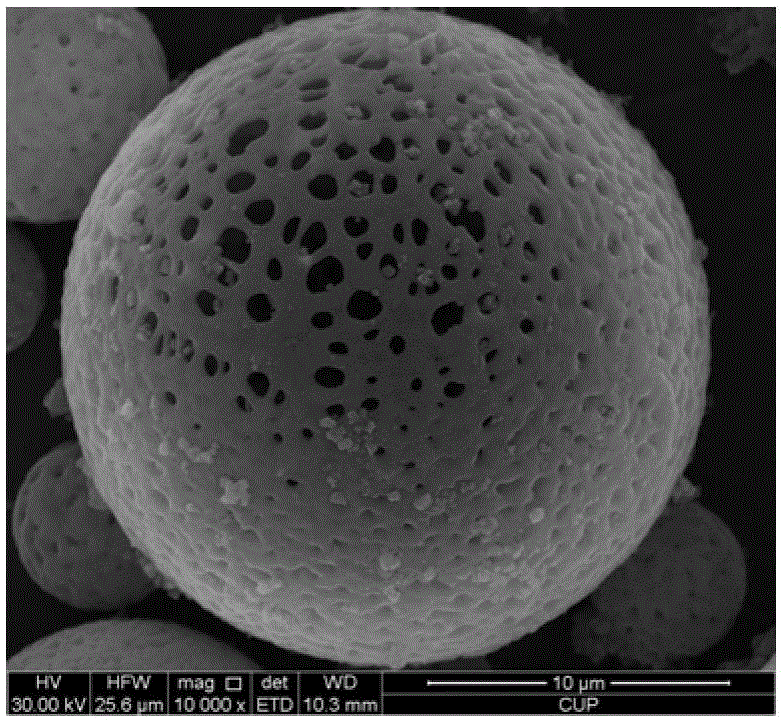

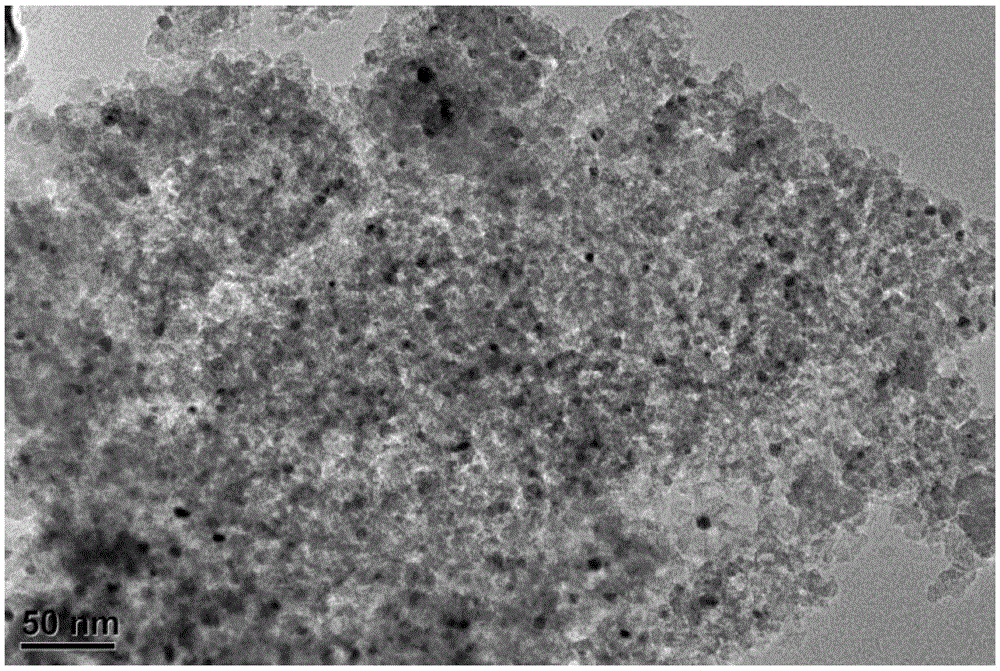

[0038] with PdCl 2 The HCl solution was used as the impregnation solution, and Pd was impregnated on the TM-SHMs by the equal volume impregnation method to prepare a heterogeneous catalyst Pd / TM-SHMs with an active metal Pd loading of 2wt.%. The transmission electron microscope (TEM) of the catalyst photos such as Figure 2a As shown, the Pd grain size distribution is as Figure 2b shown;

[0039] Dissolve 4g NBR in 100mL chlorobenzene solvent, add 0.4g heterogeneous catalyst Pd / TM-SHMs, 0.02g homogeneous catalyst triphenylphosphine rhodium chloride, 0.05g triphenylphosphine, in a high-pressure hydrogenation reactor Carry out catalytic hydrogenation reaction to obtain glue, the reaction conditions are: temperature 80°C, hydrogen pressure 6MPa, reaction time 5h;

[0040] After the reaction, the heterogeneous catalyst Pd / TM-SHMs was r...

Embodiment 2

[0042] Present embodiment provides a kind of preparation method of hydrogenated nitrile butadiene rubber, it may further comprise the steps:

[0043] With Pd(NH 3 ) 4 Cl 2 The ammonia solution was used as the impregnation solution, and Pd was loaded on TM-SHMs by ion exchange method to prepare a heterogeneous catalyst Pd / TM-SHMs with an active metal loading of 4wt.%.

[0044] Dissolve 5g NBR in 100mL acetone solvent, add 0.5g heterogeneous catalyst Pd / TM-SHMs, 0.02g homogeneous catalyst triphenylphosphine rhodium chloride, 0.05g triphenylphosphine rhodium chloride, and carry out in a high-pressure hydrogenation reactor Catalytic hydrogenation reaction to obtain glue, the reaction conditions are: temperature 60°C, hydrogen pressure 8MPa, reaction time 8h;

[0045] After the reaction, the heterogeneous catalyst Pd / TM-SHMs was recovered by centrifugation, and then the organic solvent was evaporated from the glue to obtain the product HNBR, and the degree of hydrogenation was l...

Embodiment 3

[0047] Present embodiment provides a kind of preparation method of hydrogenated nitrile butadiene rubber, it may further comprise the steps:

[0048] with RhCl 3 The HCl solution was used as the impregnating solution, and the Rh was impregnated on the TM-SHMs by the equal volume impregnation method to prepare the heterogeneous catalyst Rh / TM-SHMs with an active metal loading of 5wt.%.

[0049] Dissolve 5g NBR in 100mL tetrahydrofuran solvent, add 0.6g heterogeneous catalyst Pd / TM-SHMs, 0.02g homogeneous catalyst triphenylphosphine rhodium chloride, 0.05g triphenylphosphine, and carry out in a high-pressure hydrogenation reactor Catalytic hydrogenation reaction to obtain glue, the reaction conditions are: temperature 70°C, hydrogen pressure 5MPa, reaction time 6h;

[0050] After the reaction, the heterogeneous catalyst Rh / TM-SHMs was recovered by centrifugation, and then the organic solvent was evaporated from the glue to obtain the product HNBR, and the degree of hydrogenatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com