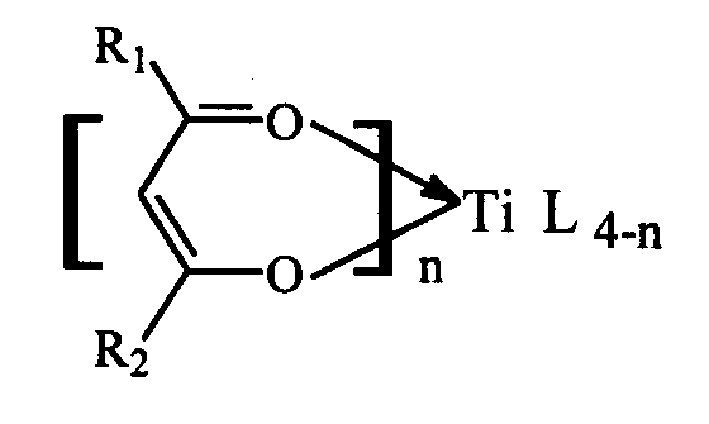

Technical method of preparing polynorbornene using beta diketone titanium non cyclopentadienyl catalyst

A technology for diketone titanium nonlocene catalyst and polynorbornene is applied in the field of preparing polynorbornene and can solve the problems of complex preparation process, low activity and poor stability of the pre-transition metal catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0014] Example 11. Preparation of the catalyst Using Schlenk technology, under the protection of argon, use a syringe to add 0.5mLTiCl to a 250mL three-neck round bottom flask successively 4 (99%) solution, 15 mL of dried toluene. A solution of 0.8586g phenol and 15mL toluene was added dropwise through a constant pressure dropping funnel, and refluxed for 2h after dropping. After cooling, add a solution of 2.0929 g of dibenzoylmethane and 15 mL of toluene dropwise through a constant pressure dropping funnel, and reflux for 4 hours after the dropwise addition. Slowly lower the temperature to obtain crystals, which are catalyst 1. Similarly, use 0.4299g phenol and 3.1311g dibenzoylmethane to obtain catalyst 2; use 1.2988g phenol and 1.0476g dibenzoylmethane to obtain catalyst 3; instead of phenol and dibenzoylmethane, add only 1.0mL Catalyst 4 was obtained from acetylacetone; Catalyst 5 was obtained from 0.8586g phenol and 1.0mL acetylacetone. The structures of these catalyst...

Embodiment 2

[0016] Catalyst 2 was used in the polymerization reaction, and all the other polymerization conditions were the same as in Example 1.

Embodiment 3

[0018] Catalyst 3 was used in the polymerization reaction, and all the other polymerization conditions were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com