Highly active supporting method of non-metallocene catalyst

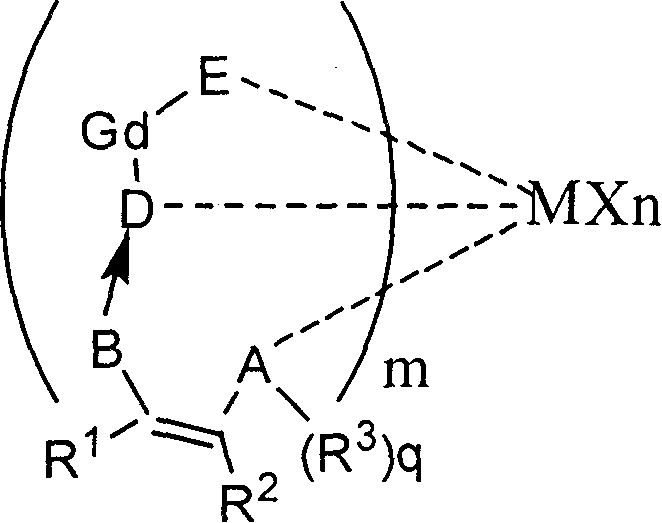

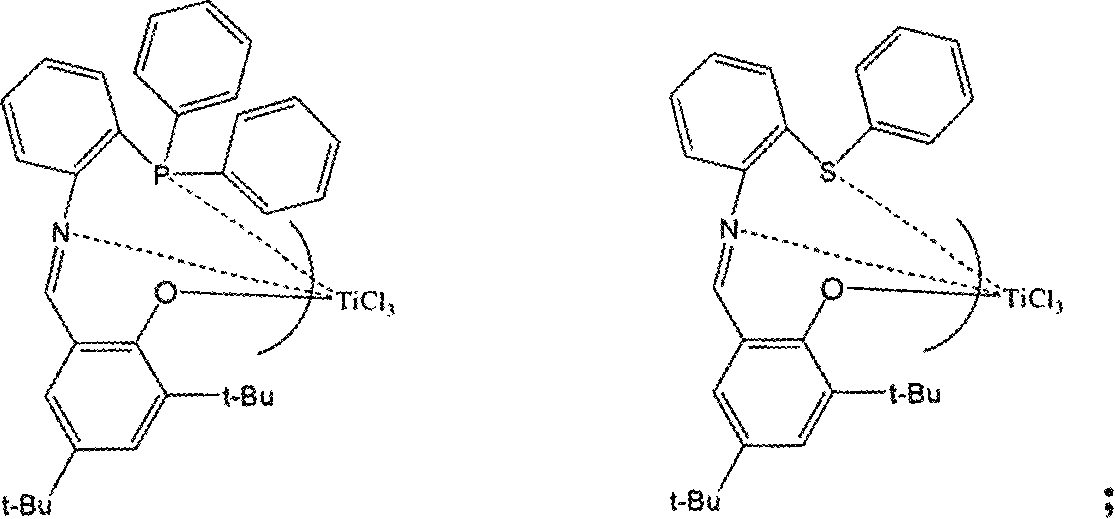

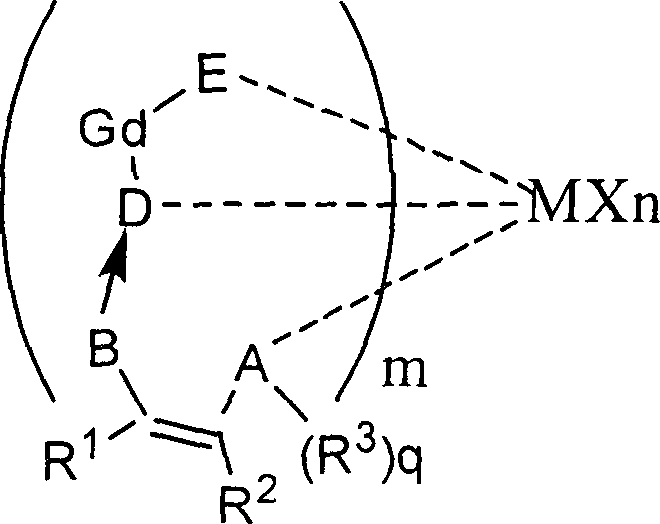

A non-metallocene and catalyst technology, applied in the field of supported non-metallocene catalysts, can solve the problems of low catalytic activity, uneconomical application of supported catalysts, and reduced catalytic olefin polymerization activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1, the highly active loading method of non-metallocene catalyst, mainly comprises the following steps:

[0071] The porous solid of the carrier adopts silica gel Grace 955, and the silica gel is heated at 500-800°C and N 2 Or continue drying or roasting under Ar atmosphere for 4-8h. Heat-activated dehydroxylated silica gel needs to be stored under an inert atmosphere.

[0072] The chemical activator adopts titanium tetrachloride; the activated carrier is reacted with titanium tetrachloride, and the modified carrier is obtained after filtering, washing, drying and pumping. The mass ratio of titanium tetrachloride and silica gel is 1: 40;

[0073] Magnesium chloride is dissolved in a tetrahydrofuran-ethanol mixed system to form a solution, and then the modified carrier is added into the solution, and fully reacted under the stirring condition of 0-60° C. to form a transparent system. The time is 1 to 48 hours, preferably 4 to 24 hours. The composite carrier...

Embodiment 1-1

[0081] Embodiment 1-1 is basically the same as Embodiment 1, but has the following changes:

[0082] Dissolve magnesium fluoride in tetrahydrofuran-methanol mixed system to form a solution.

Embodiment 1-2

[0083] Embodiment 1-2 is basically the same as Embodiment 1, but has the following changes:

[0084] Dissolve magnesium iodide in tetrahydrofuran-propanol mixed system to form a solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com