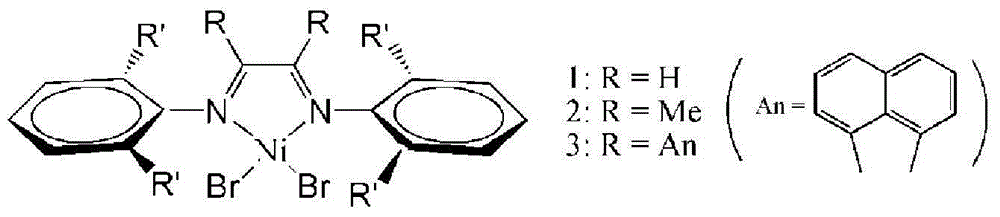

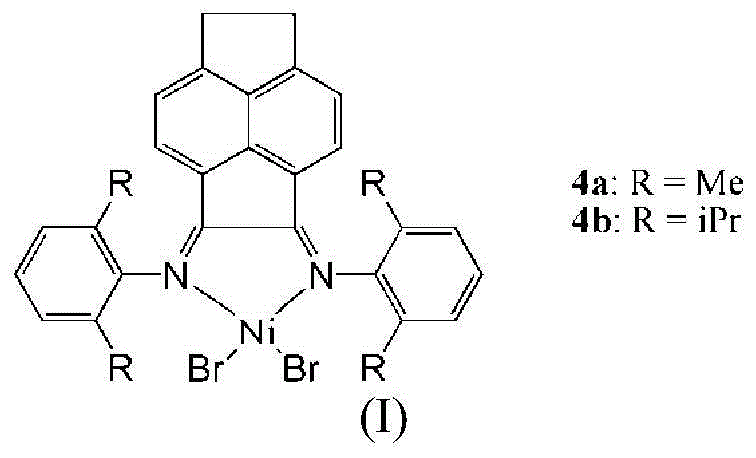

Ethylene acenaphthylene (alpha-diimine) nickel complex/alkyl aluminum chloride combined catalyst

A technology of alkyl aluminum chloride and combined catalyst is applied in the field of olefin catalytic polymerization to achieve the effects of cost reduction, good stability and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Polymerization of ethylene under normal pressure is carried out under anhydrous and oxygen-free conditions. At 60° C. and an ethylene pressure of 0.1 MPa, 40 mL of n-heptane (for polymerization) was injected into a 100 mL Schlenk bottle, and then 2.0 mmol of diethylaluminum monochloride was injected thereinto. Dissolve 10 μmol of procatalyst 4b (that is, R in the molecular formula is isopropyl) with 10 mL of toluene, and pour it into a Schlenk bottle (control the Al / Ni ratio to 200). After half an hour of polymerization, quickly drop the polymer solution into acidified methanol or acetone solution with a rubber dropper for precipitation, filter the polymer, then wash with methanol or acetone several times, and vacuum dry at 50°C to constant weight Weighed 6.7 grams of polymer. The catalyst activity is 1.34×10 6 g[mol(Ni)h]-1, the weight average molecular weight of the polymerization product is 149kg / mol, and the polydispersity coefficient is 1.9. 1 The degree of bran...

Embodiment 2

[0026] The cocatalyst monochlorodiethylaluminum was replaced by sesquiethylaluminum chloride, and other conditions and the polymer treatment method were the same as in Example 1 to obtain 6.6 grams of polymer. The catalyst activity is 1.32×10 6 g[mol(Ni)h] -1 , the weight average molecular weight of the polymerization product is 125kg / mol, and the polydispersity coefficient is 1.9. 1 The degree of branching of the polymer as determined by H-NMR was 125 / 1000 carbon atoms.

Embodiment 3

[0028] The cocatalyst monochlorodiethylaluminum was replaced by dichloroethylaluminum, and other conditions and polymer treatment methods were the same as in Example 1 to obtain 7.4 grams of polymer. The catalyst activity is 1.48×10 6 g[mol(Ni)h] -1 , the weight average molecular weight of the polymerization product is 64kg / mol, and the polydispersity coefficient is 1.7. 1 The degree of branching of the polymer as determined by H-NMR was 124 / 1000 carbon atoms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com