Weather-resistant pearlescent pigment, and preparation method and application thereof

A pearlescent pigment, weather resistance technology, used in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0097] Another method for preparing weather-resistant pearlescent pigments of the present invention adopts the following technical solutions:

[0098] A preparation method of weather-resistant pearlescent pigment, the method is divided into three steps. One, deposit cerium, aluminum oxide or hydroxide on the surface of the pearlescent pigment, specifically as follows: add 100-150 parts by weight of pearlescent pigment successively in a reactor with a mechanical stirring device, remove 1000--1200 parts by weight Ionized water, then stirred and heated to 75-85°C, lowered the pH value to 4.2 with dilute hydrochloric acid, then added 25-40 parts by weight of 3.5% cerium salt solution, and at the same time added dropwise 30% sodium hydroxide solution to maintain The pH value does not change. After the dropwise addition, raise the pH value to 5.2, continue to drop 25-40 parts by weight of 3.5% aluminum salt solution, and simultaneously add dropwise 30% sodium hydroxide solution to ...

Embodiment 1

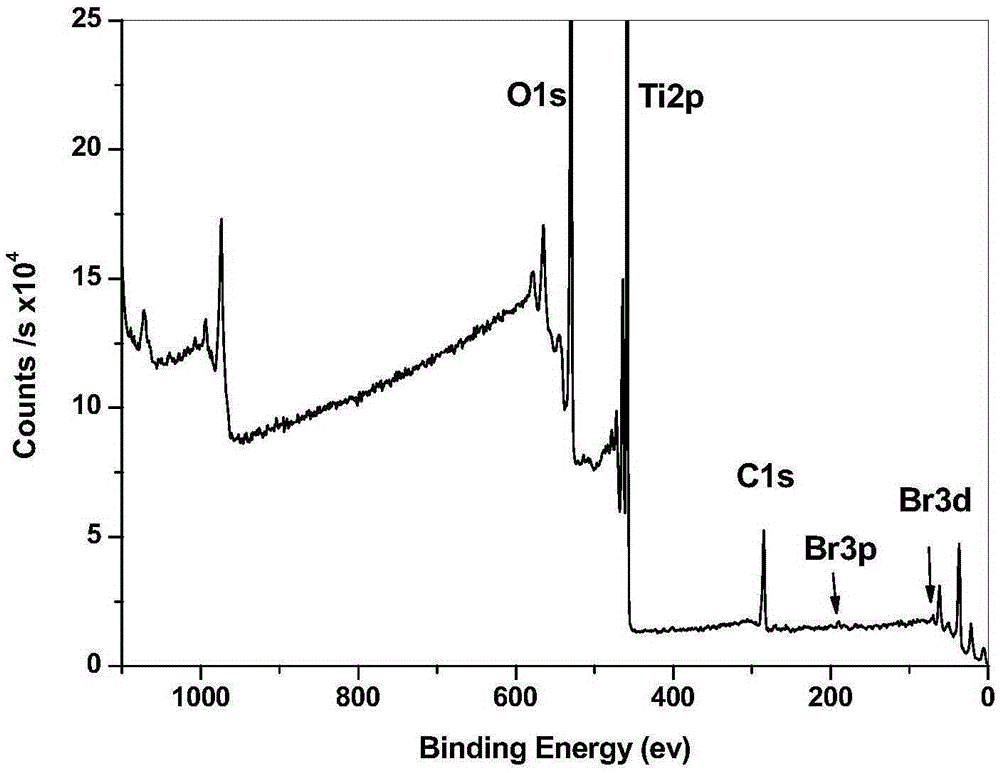

[0108] The first step: coating the inorganic layer on the surface of natural mica pearlescent pigments: add 120g of natural mica silver white pearlescent pigments (particle size 10-60μm, KC100A, Fujian Kuncai Material Technology Co., Ltd. company), 1100ml of deionized water, stirred thereupon and heated to 80°C, the pH value was reduced to 4.2 with dilute hydrochloric acid, then 30ml of 3.5% cerium chloride solution was added, and 30% of sodium hydroxide solution was added dropwise Keep the pH constant. After the dropwise addition, the pH value was raised to 5.2, and 30 ml of 3.5% aluminum chloride salt solution was added dropwise, while 30% sodium hydroxide solution was added dropwise to keep the pH value constant. After the dropwise addition, continue to stir for half an hour, filter, wash, and dry at 125° C. to obtain the first modified pearlescent pigment.

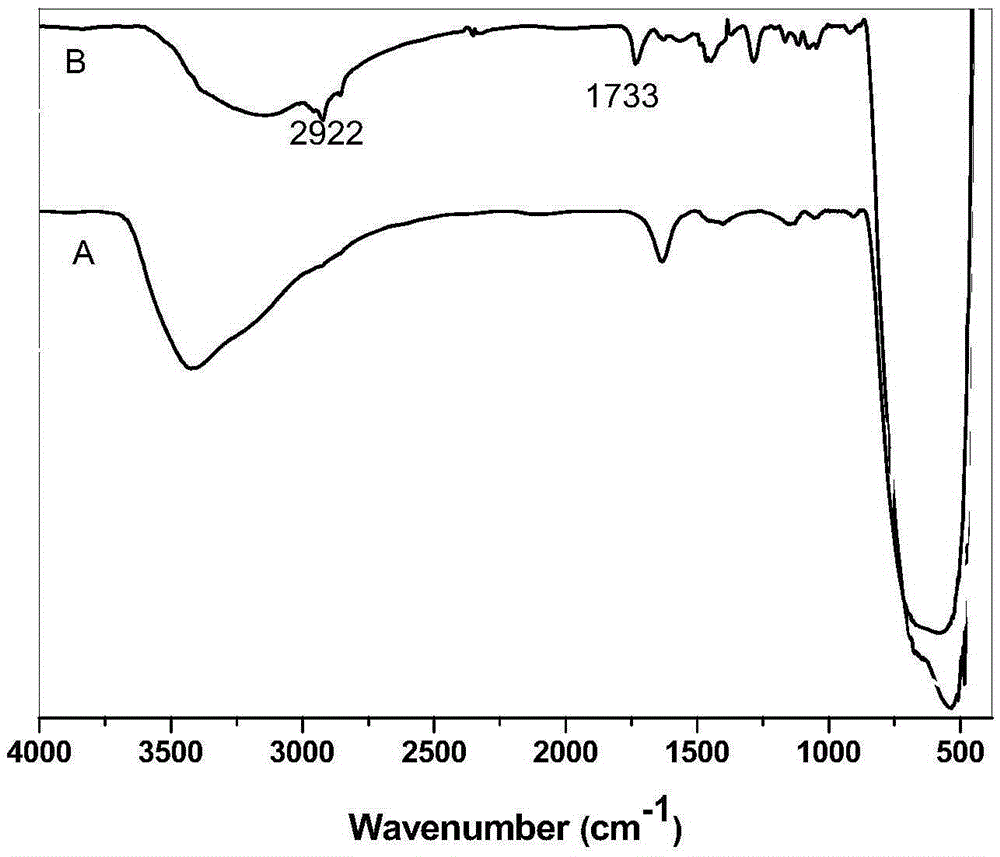

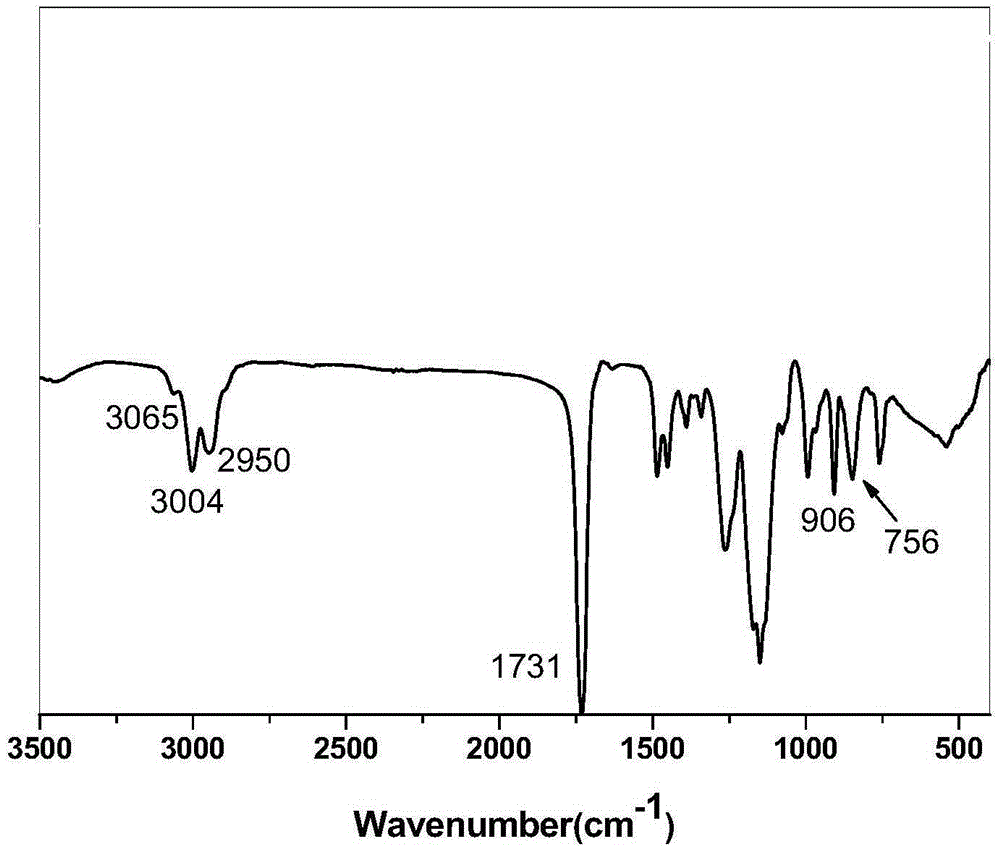

[0109] The second step: Coating the organic layer on the basis of the first modified pearlescent pigment prepared i...

Embodiment 2

[0115] The process conditions are the same as in Example 1, except that the natural mica pearlescent pigment is replaced with a synthetic mica pearlescent pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com