Three-dimensional carbon nanometer tube/graphene hybrid material and preparation method thereof

A carbon nanotube and graphene microplate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult structure control, harsh reaction conditions, complicated process steps, etc. To achieve the effects of less severe esterification reaction conditions, good thermal stability and high esterification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

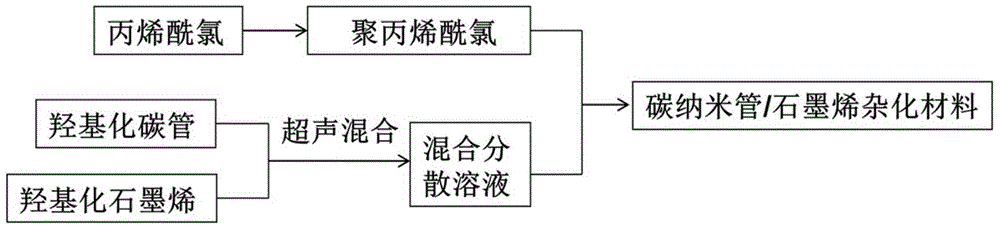

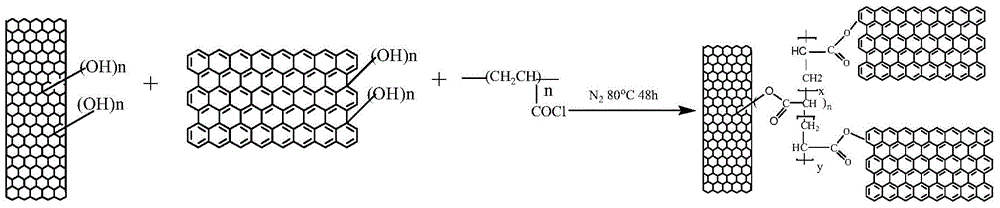

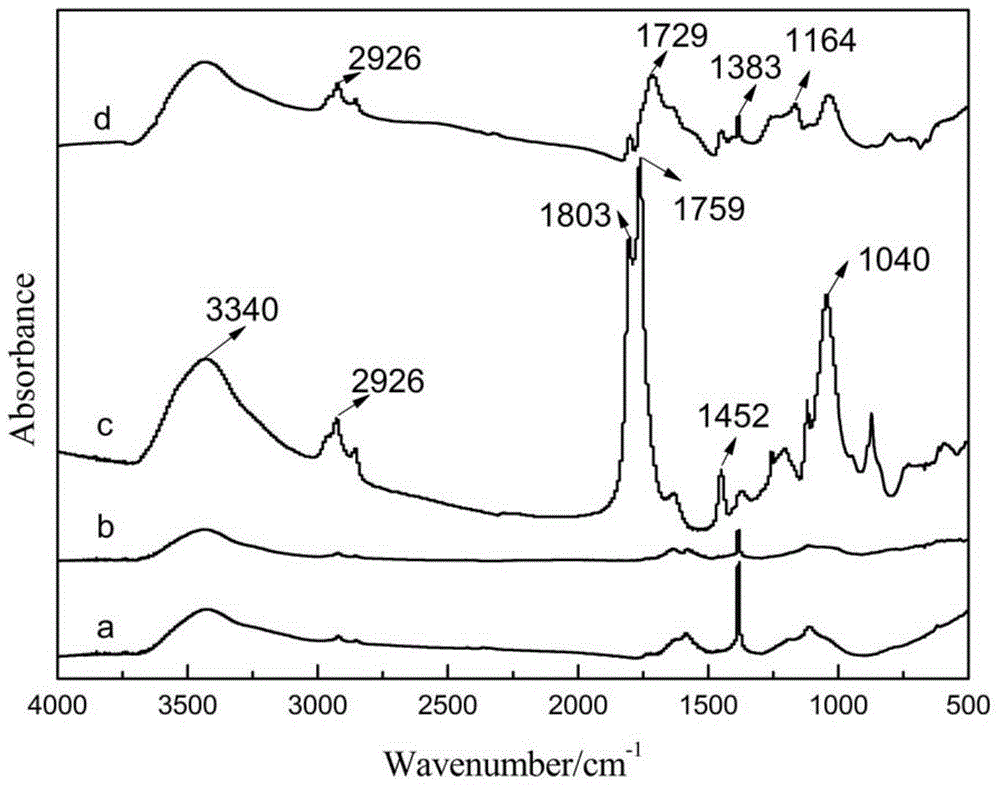

[0045] A three-dimensional carbon nanotube / graphene hybrid material, the specific preparation method is as follows:

[0046] (1) Adopt concentrated sulfuric acid and concentrated nitric acid to process carbon nanotubes and graphene microsheets respectively:

[0047] ①Put 600mg of carbon nanotubes and 30mL of concentrated sulfuric acid in a 250mL three-necked flask, stir and dissolve for 6 hours;

[0048] ② Add 30mL of concentrated nitric acid and stir to dissolve for 0.5 hours, wherein the volume ratio of concentrated sulfuric acid to concentrated nitric acid is 1:1;

[0049]③ Move the three-neck flask into a constant temperature oil bath at 140°C, and reflux for one hour; after the reaction, dilute it with 1000mL of deionized water, let it stand for 24 hours, pour off the supernatant after standing, and use a pore size of 220nm for the precipitate The mixed fiber microporous filter membrane was subjected to vacuum filtration, and repeatedly washed with deionized water until ...

Embodiment 2

[0063] A three-dimensional carbon nanotube / graphene hybrid material, the specific preparation method is as follows:

[0064] (1) Adopt concentrated sulfuric acid and concentrated nitric acid to process carbon nanotubes and graphene microsheets respectively:

[0065] ①Put 1000mg of carbon nanotubes and 60mL of concentrated sulfuric acid in a 250mL three-neck flask, stir and dissolve for 5 hours;

[0066] ② Add 20mL of concentrated nitric acid and stir to dissolve for 1 hour, wherein the volume ratio of concentrated sulfuric acid to concentrated nitric acid is 3:1;

[0067] ③ Move the three-neck flask into a constant temperature oil bath at 140°C, and reflux for one hour; after the reaction, dilute it with 1000mL of deionized water, let it stand for 24 hours, pour off the supernatant after standing, and use a pore size of 220nm for the precipitate The mixed fiber microporous filter membrane was subjected to vacuum filtration, and repeatedly washed with deionized water until the...

Embodiment 3

[0074] A three-dimensional carbon nanotube / graphene hybrid material, the specific preparation method is as follows:

[0075] (1) Adopt concentrated sulfuric acid and concentrated nitric acid to process carbon nanotubes and graphene microsheets respectively:

[0076] ①Put 100mg of carbon nanotubes and 20mL of concentrated sulfuric acid in a 250mL three-necked flask, stir and dissolve for 5 hours;

[0077] ② Add 10mL of concentrated nitric acid and stir to dissolve for 0.5 hours, wherein the volume ratio of concentrated sulfuric acid to concentrated nitric acid is 2:1;

[0078] ③ Move the three-neck flask into a constant temperature oil bath at 140°C, and reflux for one hour; after the reaction, dilute it with 1000mL of deionized water, let it stand for 24 hours, pour off the supernatant after standing, and use a pore size of 220nm for the precipitate The mixed fiber microporous filter membrane was subjected to vacuum filtration, and repeatedly washed with deionized water until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com