Acrylic acid-maleic anhydride copolymer pigment dispersing agent and preparation method thereof

A technology of pigment dispersant and maleic anhydride, applied in the direction of coating, etc., can solve the problems of weak dispersion stability and poor dispersion effect, and achieve the effects of good stability, uniform dispersion and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A pigment dispersant made of acrylic acid, maleic anhydride, catalyst, initiator and sodium hydroxide. The monomer acrylic acid is 30 parts, the ratio of maleic anhydride is 15 parts, the initiator is 2 parts of sodium persulfate, 1 part of hydrogen peroxide, and the amount of the catalyst ferrous sulfate is 25 ppm of the total monomer mass.

[0014] A certain amount of acrylic acid and maleic anhydride are dissolved in water and prepared into a 20% solution for later use. Add a certain amount of water to the reactor, add the catalyst ferrous sulfate, the addition amount is 25 ppm of the total monomer mass, start the stirrer, stir at 30 rpm for 5 minutes; at the same time increase the temperature of the reactor to 80°C. Add the prepared mixed solution of acrylic acid and maleic anhydride dropwise to the reaction kettle, control the dropping rate, and complete the dropwise addition within 3 hours. At the same time, sodium persulfate and hydrogen peroxide solution initiator...

Embodiment 2

[0017] A pigment dispersant made of acrylic acid, maleic anhydride, catalyst, initiator and sodium hydroxide. The monomer acrylic acid is 45 parts, the ratio of maleic anhydride is 9 parts, the initiator is 5 parts of sodium persulfate, 2 parts of hydrogen peroxide, and the amount of the catalyst ferrous sulfate is 90 ppm of the total monomer mass.

[0018] A certain amount of acrylic acid and maleic anhydride are dissolved in water and prepared into a 30% solution for later use. Add a certain amount of water to the reactor, add the catalyst ferrous sulfate, the addition amount is 90 ppm of the total monomer mass, start the stirrer, stir at 40 rpm for 7 minutes; at the same time increase the temperature of the reactor to 92°C. Add the prepared mixed solution of acrylic acid and maleic anhydride dropwise to the reaction kettle, control the dropping rate, and complete the dropwise addition within 4 hours. At the same time, sodium persulfate and hydrogen peroxide solution initiator...

experiment example

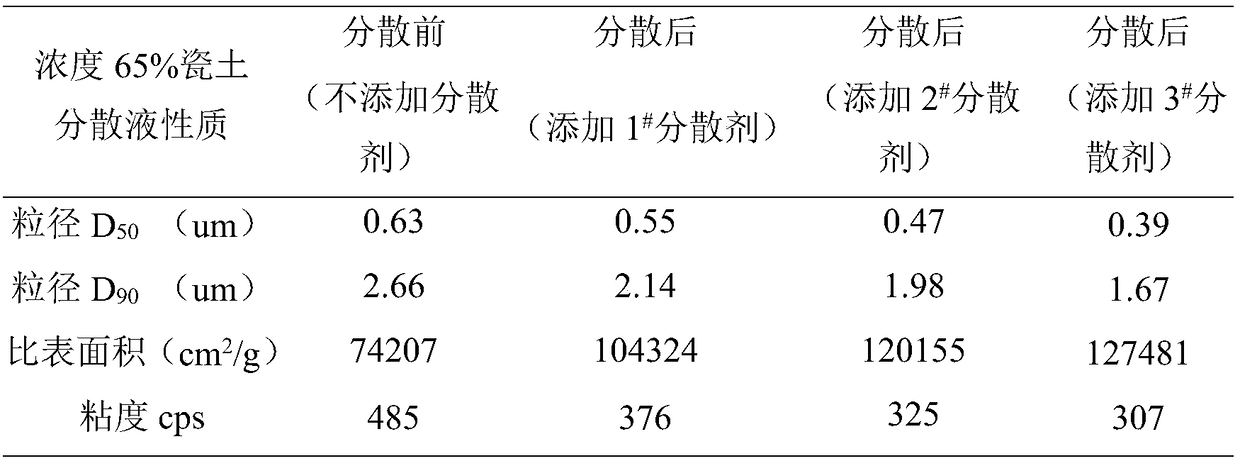

[0020] Select sodium polypropylene dispersant commonly used in paper mills as 1 # Sample, take the dispersant prepared in this application as 2 # And 3 # For the sample, the same pigment dispersion method was used to carry out the dispersion experiment of the porcelain clay pigment, and the amount of dispersant was 0.08% of the total mass of the porcelain clay. The specific test data are as follows:

[0021] Table 1 compares the dispersion effect of different dispersants:

[0022] Table 1

[0023]

[0024] It can be drawn from the table that the dispersing effect of the dispersant in this application is better than that of the commonly used commercially available sodium polyacrylate dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com