Preparation method and application for papermaking dry strength agent

A dry strength agent and reactor technology, used in papermaking, reinforcing agent addition, textiles and papermaking, etc., can solve the problems of gelation, high local concentration, local explosion, etc., to avoid environmental pollution and overcome product viscosity. , to avoid the effect of explosion and gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

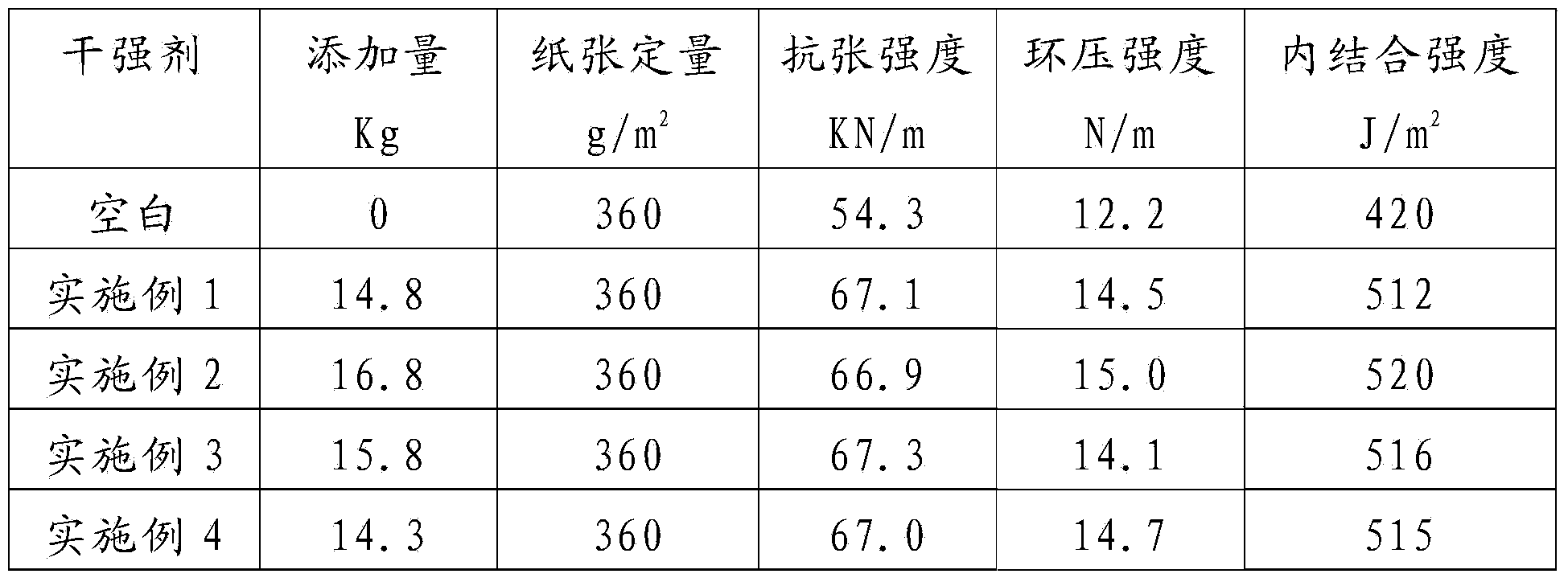

Examples

Embodiment 1

[0033] (1) Add 480kg of isopropanol and 200kg of deionized water into the reactor, stir and mix evenly, and heat up to 80-85°C;

[0034] (2) Mix 27kg of acrylic acid, 2.0kg of methyl acrylate, and 0.5kg of itaconic acid evenly to obtain dropwise solution A1; mix 120kg of acrylamide, 13kg of acrylic acid, 1.8kg of N,N-dimethylacrylamide, 25kg of DMC, 13kg acrylonitrile and 15kg deionized water were uniformly mixed to obtain drip solution A2; 0.46kg sodium persulfate and 50kg deionized water were uniformly mixed to obtain drip solution B1; 1kg sodium persulfate and 50kg deionized water were uniformly mixed to obtain Obtain dropwise solution B2;

[0035] (3) At 80-85°C, add dropwise liquids A1 and B1 to the above-mentioned reactor at a constant speed at the same time. After the polymerization reaction occurs for 1.5 hours, cool down to 35-45°C, and adjust the pH to 4-6 with NaOH , and then raise the temperature to 80-85°C, then drop the dripping solution A2 and B2 into the react...

Embodiment 2

[0038] (1) Add 600kg of n-butanol and 80kg of deionized water into the reactor, stir and mix evenly, and heat up to 80-85°C;

[0039](2) Mix 26kg of acrylic acid, 2.5kg of hydroxyethyl acrylate, 0.5kg of methyl methacrylate, and 1kg of DM evenly to obtain dropwise solution A1; mix 125kg of acrylamide, 15kg of acrylic acid, 1kg of N,N-dimethylacrylamide , 1kg maleic anhydride, 28kgDM, and 18kg deionized water were uniformly mixed to obtain dropwise solution A2; 2.5kg hydrogen peroxide (30% effective content) and 48kg deionized water were uniformly mixed to obtain dropwise solution B1; 1.5kg Mix hydrogen peroxide (effective content 30%) and 50kg deionized water evenly to obtain drip solution B2;

[0040] (3) At 80-85°C, drop the dripping solution A1 and B1 into the above-mentioned reactor at the same time at a constant speed, after the polymerization reaction occurs for 2 hours, cool down to 35-45°C, and adjust the pH to 4-6 with NaOH , and then raise the temperature to 80-85°C...

Embodiment 3

[0043] (1) Add 500kg of ethanol and 180kg of deionized water into the reactor, stir and mix evenly, and heat up to 80-85°C;

[0044] (2) Mix 30kg of acrylic acid, 2.5kg of hydroxypropyl acrylate, 0.5kg of ethyl acrylate, and 2kg of DADMAC evenly to obtain dropwise solution A1; mix 147kg of acrylamide, 19kg of Amide, 1.5kg sodium methacrylate, and 19kg deionized water were uniformly mixed to obtain drip solution A2; 0.46kg ammonium persulfate and 50kg deionized water were uniformly mixed to obtain drip solution B1; 0.6kg benzene peroxide Formyl and 50kg of deionized water were evenly mixed to obtain dropwise solution B2;

[0045] (3) At 80-85°C, drop the dripping solution A1 and B1 into the above-mentioned reactor at the same time at a constant speed, after the polymerization reaction occurs for 2 hours, cool down to 35-45°C, and adjust the pH to 4-6 with NaOH , and then raise the temperature to 80-85°C, then add the dripping solution A2 and B2 into the reactor at a constant s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com