Cationic resin regenerant and method for regenerating cationic resin with cationic resin regenerant

A technology of cation resin and regenerant, applied in the direction of ion exchange regeneration, ion exchange, chemical instruments and methods, etc., can solve problems such as affecting product quality and stability, cation resin activation cannot be carried out, etc., to avoid plasticizer pollution, The effect of saving operating procedures and easy operation in the regeneration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment is described by taking the softening of cationic resin in preparing wine as an example.

[0048] In this embodiment, the cationic resin regeneration agent is composed of the following raw materials in percentage by weight: 80% sodium citrate, 10% sodium gluconate, 5% sodium hexametaphosphate, and 5% sodium hydroxide. The sodium citrate, sodium gluconate, sodium hexametaphosphate and sodium hydroxide all use food-grade raw materials.

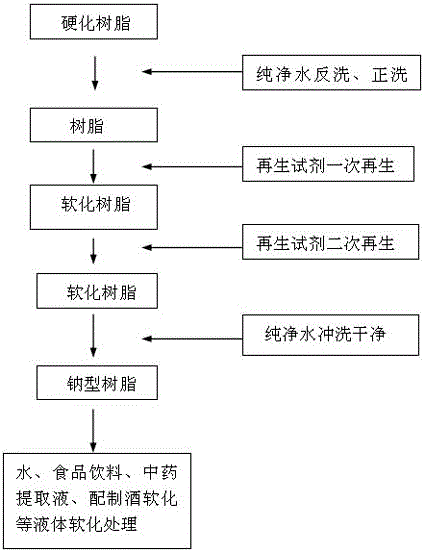

[0049] see figure 1 , utilize above-mentioned regeneration agent to carry out the method for cationic resin regeneration in the present embodiment, comprise the following steps:

[0050] (1) Rinse with pure water

[0051] After the wine preparation liquid in the resin is saturated, drain the liquid in the resin softening tank, backwash with pure water for 5 minutes, the flushing rate is 4BV / H, the resin expansion rate is 80%, and there is no visible mechanical impurity in the sample, then use pure The water is being rins...

Embodiment 2

[0072] In this embodiment, the softening of the cationic resin in the traditional Chinese medicine extract is taken as an example for illustration.

[0073] In this embodiment, the cationic resin regeneration agent is composed of the following raw materials in percentage by weight: 70% sodium citrate, 15% sodium gluconate, 8% sodium hexametaphosphate, and 7% sodium hydroxide. The sodium citrate, sodium gluconate, sodium hexametaphosphate and sodium hydroxide all use food-grade raw materials.

[0074] Utilize above-mentioned regeneration agent to carry out the method for cationic resin regeneration in the present embodiment, comprise the following steps:

[0075] (1) Rinse with pure water

[0076] After the Chinese medicine extract in the resin is saturated, drain the material liquid in the resin softening tank, backwash with pure water for 10 minutes, the flushing rate is 2BV / H, the resin expansion rate is 100%, and there are no visible mechanical impurities in the sample, th...

Embodiment 3

[0085] In this embodiment, the softening of the cationic resin during the preparation of pure water is taken as an example for illustration.

[0086] In this embodiment, the cationic resin regeneration agent is composed of the following raw materials in percentage by weight: 72% sodium citrate, 12% sodium gluconate, 15% sodium hexametaphosphate, and 1% sodium hydroxide. The sodium citrate, sodium gluconate, sodium hexametaphosphate and sodium hydroxide all use food-grade raw materials.

[0087] Utilize above-mentioned regeneration agent to carry out the method for cationic resin regeneration in the present embodiment, comprise the following steps:

[0088] (1) Rinse with pure water

[0089] After the softening material liquid in the resin is saturated, drain the material liquid in the resin softening tank, backwash with pure water for 8 minutes, the washing rate is 5BV / H, the resin expansion rate is 50%, and there is no visible mechanical impurity in the sample, then use pure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Chroma | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com