Adhesive material for adhesive tapes and preparation method thereof

A technology of adhesive materials and tapes, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems that are difficult to meet the performance requirements of metal film switches, computer keyboards, low peel strength of ordinary pressure-sensitive tapes, and adhesive tapes. Reduce the cohesion of the layer and other problems, and achieve the effects of avoiding aging yellowing, excellent light transmission, and reducing reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

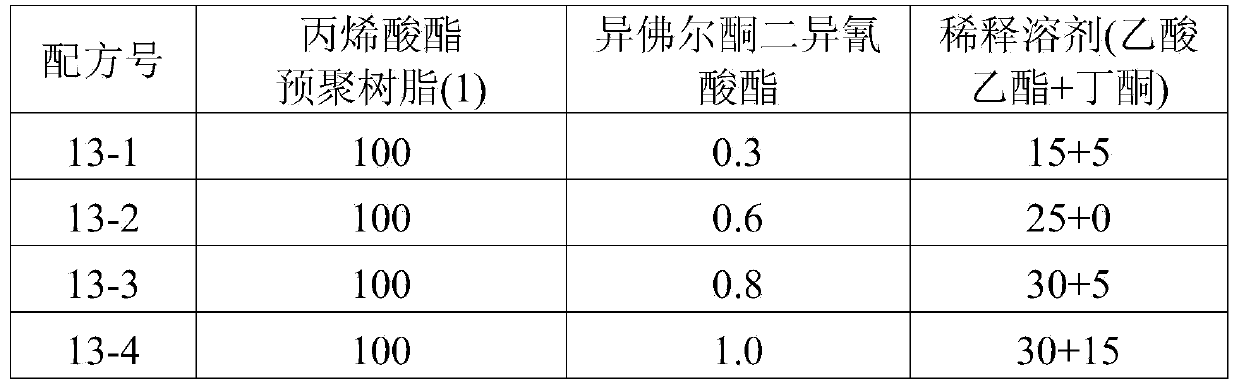

[0033] At room temperature, 35kg butyl acrylate, 15kg isooctyl acrylate, 25kg ethyl methacrylate, 20kg methoxyethyl acrylate, 10kg glycidyl methacrylate, 120kg solvent (ethyl acetate: methyl ethyl ketone=1:1) , And 0.8kg of benzoyl peroxide were added to the reactor equipped with a reflux device, stirred at 200rpm, and mixed uniformly; gradually heated to 75℃ under nitrogen protection, reacted for 4h, stopped heating, and then added 38.7 Kg of solvent (ethyl acetate: methyl ethyl ketone=1:1) is mixed uniformly, cooled to room temperature and discharged, and acrylic prepolymerized resin (1) with a solid content of 40% is prepared for use.

Embodiment 2

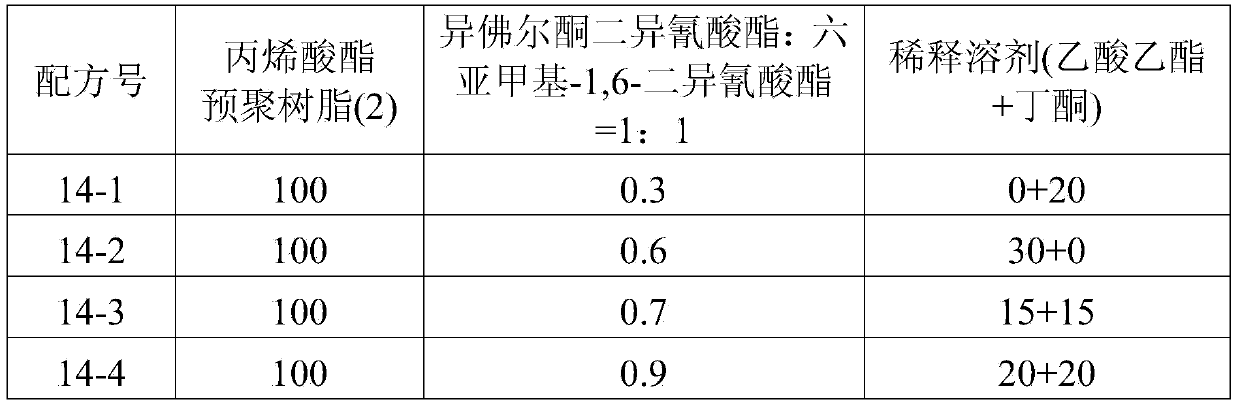

[0035] At room temperature 35kg butyl acrylate, 16kg isooctyl acrylate, 28kg ethyl methacrylate, 30kg methoxyethyl acrylate, 15kg glycidyl methacrylate, 120kg solvent (ethyl acetate: methyl ethyl ketone=1:1) , And 1.0 kg of benzoyl peroxide were added to the reaction kettle with a reflux device, stirred at 200 rpm, and mixed uniformly; under the protection of nitrogen, the temperature was gradually increased to 70°C, reacted for 4 hours, the heating was stopped, and then 67.5 Kg of solvent (ethyl acetate: methyl ethyl ketone=1:1) is mixed uniformly, cooled to room temperature and discharged, and acrylic prepolymer resin (2) with a solid content of 40% is prepared for use.

Embodiment 3

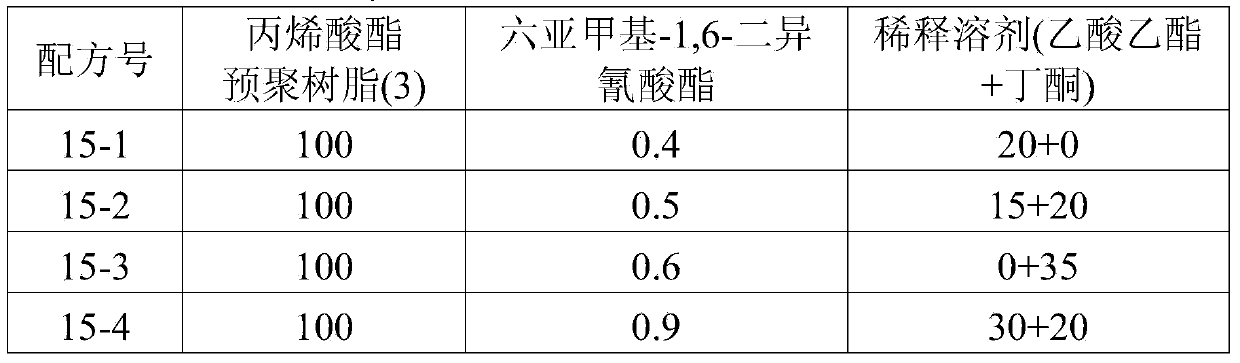

[0037] Combine 35kg butyl acrylate, 18kg isooctyl acrylate, 35kg ethyl methacrylate, 25kg methoxyethyl acrylate, 10kg glycidyl methacrylate, 120kg solvent (ethyl acetate: methyl ethyl ketone=1:1) at room temperature , And 1.0kg of azobisbutyronitrile were added to the reactor with reflux device, stirred at 200rpm, and mixed uniformly; gradually heated to 75℃ under nitrogen protection, reacted for 4h, stopped heating, and then added 66kg The solvents (ethyl acetate: methyl ethyl ketone=1:1) are mixed uniformly, cooled to room temperature and discharged, and the acrylic prepolymer resin (3) with a solid content of 40% is prepared for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com