Silicon composite waterborne acrylic emulsion and preparation method thereof

A technology of water-based acrylic acid and butyl acrylate, which is applied in the field of architectural coatings and its preparation, can solve the problems of difficult dispersion of particles, poor color development, and high processing cost of silicon-acrylic emulsion, so as to prolong reaction time, improve film-forming performance, and improve exhibition color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of silicon composite aqueous acrylic acid emulsion of the present invention comprises the following steps:

[0024] a: Preparation of pre-emulsion: Add water, butyl acrylate, methyl methacrylate, isooctyl acrylate, 0-100% of the total amount of functional monomers, and emulsifier to the pre-emulsification tank at normal temperature and pressure. Stir for 20-40 minutes to mix it into a uniform pre-emulsion;

[0025] b: Raise the temperature of the reactor to 85-90°C, add the initiator and 5-10% pre-emulsion, and control the temperature at 80-85°C, and the reaction time is 20-40 minutes;

[0026] c: Raise the temperature of the reactor to 85-90°C, and add the remaining pre-emulsion to the reactor dropwise for 2-8 hours, 1-3 hours before the completion of the above drop operation, at the same time to the reaction Add the remaining functional monomers in step a dropwise to the kettle, and ensure that the pre-emulsion and the functional monomers are a...

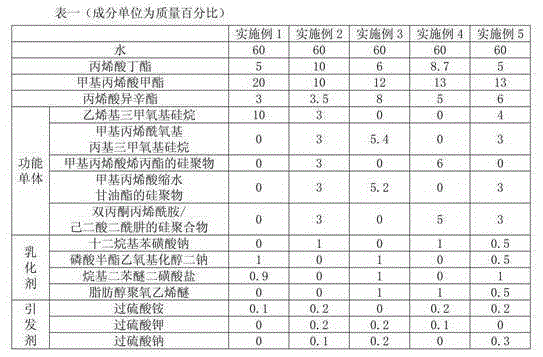

Embodiment 1

[0032] The silicon composite water-based acrylic emulsion of the present invention mainly includes water, butyl acrylate, methyl methacrylate, isooctyl acrylate, vinyltrimethoxysilane, phosphoric acid half ester ethoxylated alcohol disodium, alkyl diphenyl ether Disulfonate and ammonium persulfate, the contents of the above components are calculated by mass percentage: water 60%, butyl acrylate 5%, methyl methacrylate 20%, isooctyl acrylate 3%, vinyl trimethoxy Silane 10%, Disodium Phosphate Half Ethoxylate Alcohol 1%, Alkyl Diphenyl Ether Disulfonate 0.9%, Ammonium Persulfate 0.1%.

[0033] The preparation method of silicon composite aqueous acrylic acid emulsion of the present invention may further comprise the steps:

[0034] a: Preparation of pre-emulsion: Add water, butyl acrylate, methyl methacrylate, isooctyl acrylate, and emulsifier to the pre-emulsification tank at normal temperature and pressure, and stir for 20 minutes to form a uniform pre-emulsification liquid; ...

Embodiment 2

[0041] The silicon composite water-based acrylic emulsion of the present invention mainly includes water, butyl acrylate, methyl methacrylate, isooctyl acrylate, vinyl trimethoxysilane, methacryloxypropyl trimethoxysilane, methacrylic acid Allyl ester silicone polymer, glycidyl methacrylate silicone polymer, diacetone acrylamide / adipate dihydrazide silicone polymer, sodium dodecylbenzenesulfonate, ammonium persulfate, persulfuric acid Potassium and sodium persulfate, the contents of the above components are calculated by mass percentage: water 60%, butyl acrylate 10%, methyl methacrylate 10%, isooctyl acrylate 3.5%, vinyltrimethoxysilane 3% , Methacryloxypropyltrimethoxysilane 3%, Silicone Polymer of Allyl Methacrylate 3%, Silicone Polymer of Glycidyl Methacrylate 3%, Diacetone Acrylamide / Adipic Acid Silicon polymer of dihydrazide 3%, sodium dodecylbenzenesulfonate 1%, ammonium persulfate 0.2%, potassium persulfate 0.2%, sodium persulfate 0.1%.

[0042] The preparation method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com