High-viscosity yellowing-resistant explosion-proof film adhesive, adhesive tape and preparation method of adhesive tape

A technology of anti-yellowing and explosion-proof film, which is applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., and can solve the problem of low viscosity of acrylic glue, poor die-cutting performance, yellowing of colloid color, etc. problem, to achieve the effect of low initiator residue, improved peeling force and long holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

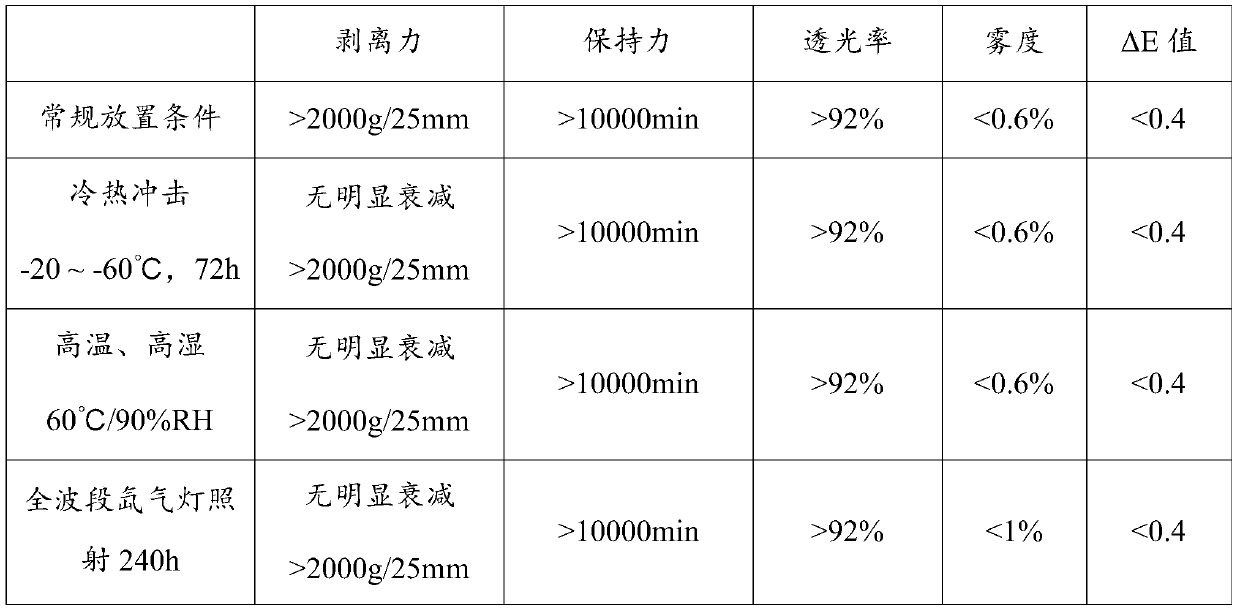

Examples

Embodiment 1

[0022] This embodiment provides a high-viscosity anti-yellowing explosion-proof film glue, including the following components by weight: 100 parts of acrylic glue, 8 parts of hydrogenated rosin pentaerythritol ester 100D, 0.1 part of isocyanate curing agent, epoxy curing agent 0.05 parts of agent, 30 parts of ethyl acetate, 30 parts of toluene.

[0023] The acrylic glue is prepared by reacting the following components in parts by weight: 26 parts of isooctyl acrylate, 3 parts of acrylic acid, 0.5 part of hydroxyethyl acrylate, 5 parts of methyl acrylate, 65 parts of ethyl acetate, 0.5 parts of azodiisobutyronitrile;

[0024] The synthesis process of the above-mentioned acrylic glue is as follows: the temperature of the above-mentioned monomer and solvent (ethyl acetate) is raised to 65-70° C., and the initiator (azobisisobutyronitrile) is added dropwise for 10 hours to obtain a solid content of 35%. Acrylic glue with a molecular weight of 500,000 to 800,000.

Embodiment 2

[0026] This embodiment provides a high-viscosity anti-yellowing explosion-proof film glue, including the following components by weight: 100 parts of acrylic glue, 8 parts of hydrogenated rosin pentaerythritol ester 5100F, 0.5 parts of isocyanate curing agent, epoxy curing agent 0.1 parts of agent, 30 parts of ethyl acetate, 30 parts of toluene.

[0027] The acrylic glue is prepared by reacting the following components in parts by weight: 30 parts of isooctyl acrylate, 5 parts of acrylic acid, 1 part of hydroxyethyl acrylate, 10 parts of methyl acrylate, 53 parts of ethyl acetate, even 1 part of azodiisobutyronitrile;

[0028] The synthesis process of the above-mentioned acrylic glue is as follows: the above-mentioned monomer and solvent (ethyl acetate) are heated to 65-70°C, and the initiator (azobisisobutyronitrile) is added dropwise for 10 hours to obtain a solid content of 47%, a molecular weight 500,000 to 800,000 acrylic glue.

Embodiment 3

[0030] This embodiment provides a high-viscosity anti-yellowing explosion-proof film glue, including the following components by weight: 100 parts of acrylic glue, 8 parts of terpene phenol TP2019, 0.3 parts of isocyanate curing agent, epoxy curing agent 0.08 parts, 30 parts of ethyl acetate, 30 parts of toluene.

[0031] The acrylic glue is prepared by reacting the following components in parts by weight: 28 parts of isooctyl acrylate, 4 parts of acrylic acid, 0.8 parts of hydroxyethyl acrylate, 8 parts of methyl acrylate, 58.4 parts of ethyl acetate, 0.8 parts of azodiisobutyronitrile;

[0032] The synthesis process of the above-mentioned acrylic glue is as follows: the temperature of the above-mentioned monomer and solvent (ethyl acetate) is raised to 65-70° C., and the initiator (azobisisobutyronitrile) is added dropwise for 10 hours to obtain a solid content of 41.6%, Acrylic glue with a molecular weight of 500,000 to 800,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com