Composite film and preparation method thereof

A composite film and composite roll technology, applied in chemical instruments and methods, flat products, and other household appliances, can solve the problems of environmental and human hazards, inapplicability to mass production, and difficulty in expanding production, etc., to reduce pollution , excellent mechanical properties, and good industrial promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A composite membrane has an A / B / A three-layer structure.

[0057] The A layer is modified polyε-caprolactone, including the following components by weight: 60 parts of polyε-caprolactone, 5 parts of polylactic acid-glycolic acid copolymer, poly(ε-caprolactone -2 parts of L-lactide) random copolymer, 2 parts of compatibilizer, 0.5 parts of Fischer-Tropsch wax, 2 parts of stearyl stearate, 12 parts of modified nano-calcium carbonate, 2 parts of hyperdispersant, 4 parts of montmorillonite, 5 parts of thermoplastic starch, 4.5 parts of acetyl tributyl citrate, 0.3 parts of chitosan, 15 parts of antistatic agent, triethylene glycol bis[3-(3-tert-butyl-5 -methyl-4-hydroxyphenyl) propionate] 0.3 parts.

[0058] The thickness of layer A is 80 μm.

[0059] The preparation steps of described compatibilizer are as follows:

[0060] Mix 60 parts by weight of polyε-caprolactone (or polylactic acid-glycolic acid copolymer), 5 parts by weight of monomer glycidyl methacrylate, and 0...

Embodiment 2

[0073] A composite film, the composite film has an A / B / A / C four-layer structure.

[0074] The A layer is modified polyε-caprolactone, including the following components by weight: 150 parts of polyε-caprolactone, 30 parts of polylactic acid-glycolic acid copolymer, poly(ε-caprolactone -L-lactide) random copolymer 15 parts, glycidyl methacrylate grafted polyε-caprolactone 11 parts, glycidyl methacrylate grafted polylactic acid-glycolic acid copolymer 3 parts, sheet 0.15 parts of graphite, 0.15 parts of stearic acid, 22 parts of modified nano calcium carbonate, 4 parts of hyperdispersant, 9 parts of montmorillonite, 16 parts of thermoplastic starch, 15 parts of polyethylene glycol, 1.1 parts of chitosan, 15 parts of electrostatic agent, 0.1 part of epigallocatechin gallate.

[0075] The thickness of the A layer was 15 μm.

[0076] The preparation steps of glycidyl methacrylate graft poly-ε-caprolactone / glycidyl methacrylate graft polylactic acid-glycolic acid copolymer are as fo...

Embodiment 3

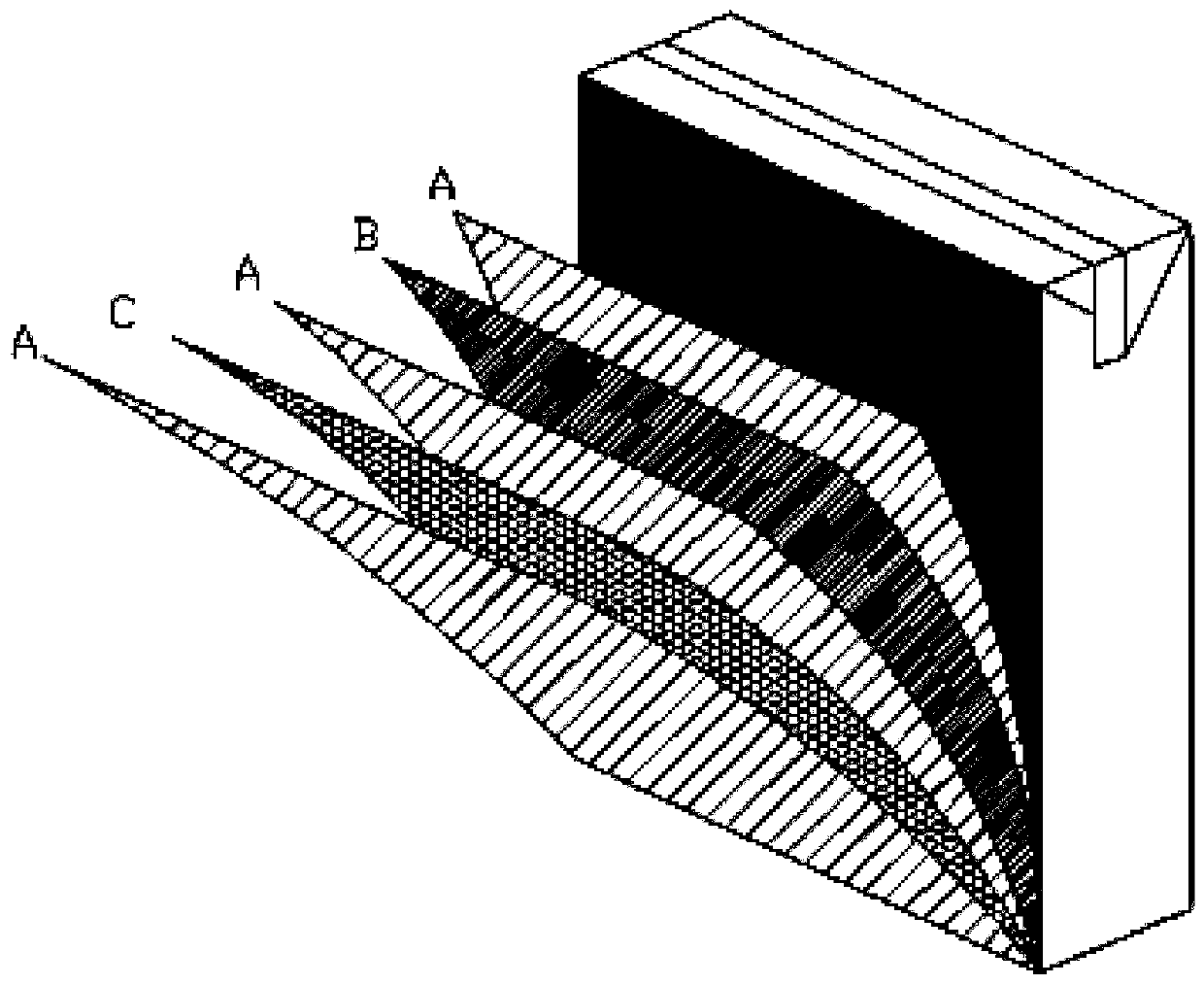

[0094] A composite film has a five-layer structure of A / B / A / C / A. Three layers of A are used to protect layers B and C and enhance the sealing performance. The structural schematic diagram of the multilayer composite film is as follows figure 1 shown.

[0095] The A layer is modified polyε-caprolactone, including the following components by weight: 120 parts of polyε-caprolactone, 20 parts of polylactic acid-glycolic acid copolymer, poly(ε-caprolactone -10 parts of L-lactide) random copolymer, 9 parts of glycidyl methacrylate grafted polyε-caprolactone, 9 parts of glycidyl methacrylate grafted polylactic acid-glycolic acid copolymer, cyclo 2 parts of oxygenated soybean oil, 4 parts of ethylene bis stearamide, 20 parts of modified nano calcium carbonate, 6 parts of hyperdispersant, 11 parts of montmorillonite, 20 parts of thermoplastic starch, 15 parts of diacetyl epoxy vegetable oil glyceride, 3 parts of chitosan, 20 parts of antistatic agent, 0.3 part of anthocyanin.

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com